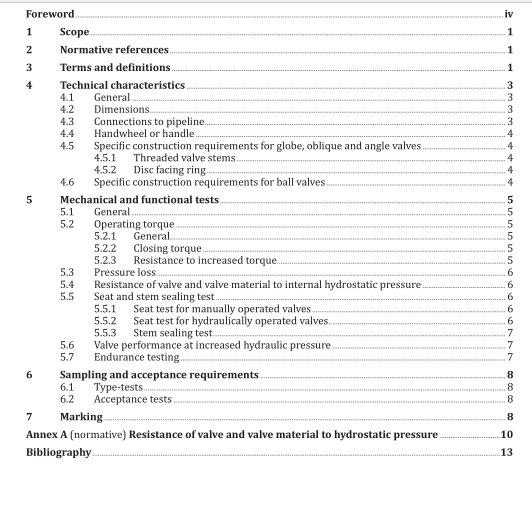

BS ISO 24649:2022 pdf download.Agricultural irrigation equipment — Manually and hydraulically operated plastics valves

4 Technical characteristics

4.1 General

The valves are intended for installation in irrigation piping networks, using water at temperatures up to 60 °C. They can be fitted with handwheels or add-on automatic control mechanisms.

All valve components that come in contact with water shall be suitable for use with water, fertilizers and chemicals commonly used in irrigation, including treated sewage water.

The body material shall be opaque.

Plastics materials shall be UV resistant.

All parts of the valve shall be of good workmanship, whole and smooth, and shall contain no holes, air bubbles, flash, projections or any other defects that could impair performance or cause injury.

All spare parts of valves shall be made available by the manufacturer within the guarantee period.

On request, the manufacturer shall supply any available information on the resistance of the valve to corrosive attack by fertilizers and chemicals used in agriculture.

NOTE Guidance on chemical resistance can be found in ISO/TR 10358 (for plastics) and ISO/TR 7620 (for rubbers).

Operating conditions, including pressures, are as specified by the manufacturer.

4.2 Dimensions

The face-to-face dimensions of valves for use in flanged pipe systems shall be selected from ISO 5752.

For all other types of end connections, the selection of the face-to-face dimensions shall be the responsibility of the manufacturer.

4.3 Connections to pipeline

The flanged connection dimensions of the valve to the pipeline shall be in accordance with ISO 7005-1 or ISO 9624.

In valves with threaded ends intended for direct connection to the pipeline, the threads shall be in accordance with ISO 7-1. However, other threads are allowed, provided that a suitable adaptor is supplied with each threaded connection such that it complies with ISO 7-1.

4.4 Handwheel or handle

The handwheel or handle shall be free from sharp projections, burrs or other defects that could cause injury. The handwheel or handle shall be securely connected to the valve stem and shall be replaceable.

NOTE The handwheel and mechanical stem in hydraulically operated plastics valves are not used for closing or opening the valve, but only for limiting the stroke of the obturator when the user wants to limit the flow.

4.5 Specific construction requirements for globe, oblique and angle valves

4.5.1 Threaded valve stems

The threads of the valve stems shall be as designed by the manufacturer to be self-locking.

The valve stem shall be of sufficient length to permit full closure of the valve when the handwheel or handle is mounted on the stem and the disc facing ring is removed.

4.5.2 Disc facing ring

4.5.2.1 General

The disc facing ring, if used, shall remain securely attached to the disc when in operation, but shall be removable for replacement without requiring removal of the valve from the system — with or without the closing disc.

When the disc facing ring is of elastomeric material, the material shall meet the requirements given in 4.5.2.2 to 4.5.2.4.

4.5.2.2 Hardness

Test the hardness of the disc facing ring in accordance with ISO 48-2, using methods N or M, depending on the disc facing ring shape. The hardness value shall be defined by the manufacturer.

4.5.2.3 Compression set

Test the compression set of the disc facing ring in accordance with ISO 815-1 for 24 h at 70 °C. The compression set after test shall not exceed 20 %.

4.5.2.4 Ageing

Repeat the hardness test (see 4.5.2.2) after keeping the disc facing ring at 70 °C for 16 h, in accordance with ISO 188 (accelerated ageing in oxygen). The change in hardness due to ageing shall be in the range of −5 to + 8 Shore A.

4.6 Specific construction requirements for ball valves

4.6.1 The stem shall be provided with a seal to ensure tightness.

The seal shall be of elastomeric or other material of suitable mechanical properties.

4.6.2 If the seal is of O-ring shape, the hardness of the O-rings shall be determined using the test method specified in ISO 48-2 and shall be 60 to 80 Shore A ±5.

The compression set of the O-ring material shall be determined using the test method given in ISO 815-1 (22 h at 70 °C) and shall not be more than 20 %.BS ISO 24649 pdf download.BS ISO 24649 pdf download