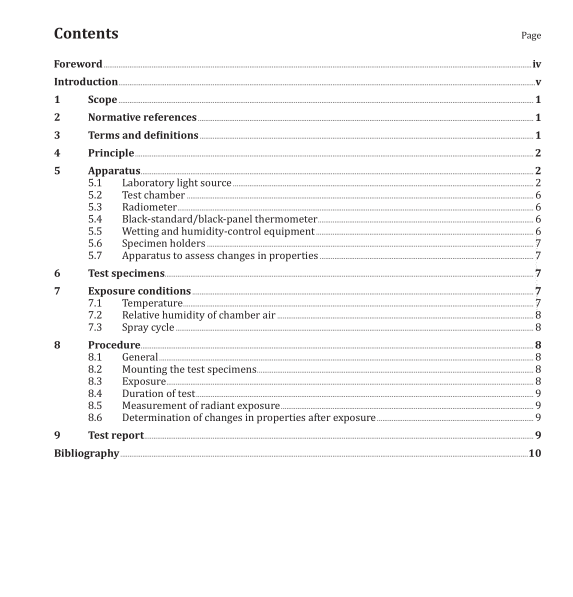

ISO 16474-4:2013 pdf download.Paints and varnishes — Methods of exposure to laboratory light sources — Part 4: Open-flame carbon-arc lamps

Note 2 to entry: If the irradiance E is constant throughout the whole exposure time, the radiant exposure H is given simply by the product of E and t.

4 Principle

4.1 Specimens of the materials to be tested are exposed to glass-filtered open-flame carbon-arc light, to heat, to relative humidity and to water (see 4.3) under controlled environmental conditions.

4.2 The exposure conditions may be varied by selection of

a) the light filter(s);

b) the temperature during light exposure;

c) the relative humidity of the chamber air during light and dark exposures, when test conditions requiring control of humidity are used;

d) the type of wetting (see 4.3);

e) the water temperature and wetting cycle;

f) the timing of the light/dark cycle.

4.3 Wetting is usually produced by spraying the test specimens with demineralised/ deionized water or by condensation of water vapour onto the surfaces of the specimens.

4.4 The procedure may include measurements of the irradiance and radiant exposure in the plane of the specimens.

4.5 It is recommended that a similar material of known performance (a control) be exposed simultaneously with the test specimens to provide a standard for comparative purposes.

4.6 Intercomparison of results obtained from the test specimens exposed in different types of apparatus should not be made unless an appropriate statistical relationship has been established between the apparatuses for the particular material to be tested.

5 Apparatus

5.1 Laboratory light source

5.1.1 General

Open-flame carbon-arc light sources typically use one, three or four pairs of carbon rods which contain a mixture of rare-earth metal salts and have a surface coating of a metal such as copper. An electric current is passed between the carbon rods which burn, giving off ultraviolet, visible and infrared radiation. The pairs of carbon rods are burned in sequence, with one pair burning at any one time.

Use the carbon rods recommended by the manufacturer of the apparatus. The radiation reaching the specimens passes through glass filters. Three types of glass filter are used in practice. Tables 1 and 2 show the typical relative spectral power distribution for open-flame carbon-arc lamps with daylight and window-glass filters, respectively. When extended-UV filters are used, the relative spectral power distribution shall meet the requirements of Table 3.

NOTE Solar spectral irradiance for a number of different atmospheric conditions is described in CIE No. 85.

The benchmark daylight used in this part of ISO 16474 is that defined in CIE No. 85:1989, Table 4.

5.1.2 Spectral irradiance of open-flame carbon-arc lamps with daylight filters (Type 1)

The data in Table 1 are typical of an open-flame carbon-arc lamp with glass filters used to simulate daylight (see CIE No. 85:1989, Table 4).

5.1.3 Spectral irradiance of open-flame carbon-arc lamps with window glass filters (Type 2)

The data in Table 2 are typical of an open-flame carbon-arc lamp with window-glass filters.

5.1.4 Spectral irradiance of open-flame carbon-arc lamps with extended-UV filters (Type 3)

The data in Table 3 are typical of an open-flame carbon-arc lamp with extended-UV filters. A typical example of a suitable type 3 filter is that commonly known as Corex 7058 1) .

5.1.5 Factors which can affect the spectral power distribution of open-flame carbon-arc lamps

The following factors can affect the spectral power distribution:

a) differences in the composition and thickness of the filters can have large effects on the amount of short-wavelength UV radiation transmitted;

b) accumulation of dirt or other residues on the filter can affect the filter transmission properties;

c) differences in the composition of the metallic salts used in the carbon rods can affect the spectral power distribution.

5.1.6 Irradiance uniformity

The irradiance at any position in the area used for specimen exposure shall be at least 80 % of the maximum irradiance. Requirements for periodic repositioning of specimens when this requirement is not met are described in ISO 16474-1.

For some materials of high reflectivity, or/and high sensitivity to irradiance and temperature, periodic repositioning of specimens is recommended to ensure uniformity of exposures, even when the irradiance uniformity in the exposure area is within the limits so that repositioning is not required.ISO 16474-4 pdf download.ISO 16474-4-2013 pdf download