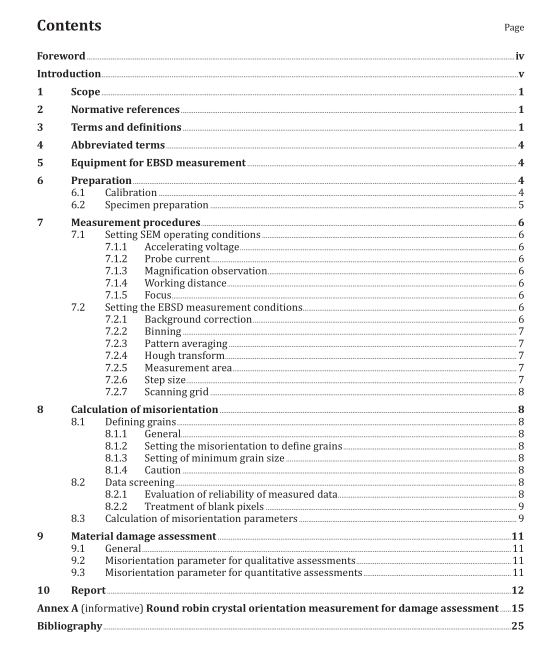

BS ISO 23703:2022 pdf download.Microbeam analysis — Guidelines for misorientation analysis to assess mechanical damage of austenitic stainless steel by electron backscatter diffraction (EBSD).

7 Measurement procedures

7.1 Setting SEM operating conditions

7.1.1 Accelerating voltage

Accelerating voltage ranging between 10 kV and 20 kV is recommended to get reasonable EBSD patterns.

Increasing the accelerating voltage may result in increasing beam spread in the specimen, and hence make the spatial resolution worse. It depends on the specimen Z number, but in most cases, there is no merit to use higher accelerating voltage more than 20 kV with recent high sensitivity image detectors.

See ISO 24173:2009, 5.3.1.

7.1.2 Probe current

Increasing the probe current increases the number of electrons contributing to the diffraction pattern and it will give brighter EBSD patterns. This improves the signal/noise ration of the EBSD patterns resulting in better band detection and better orientation determination. Therefore, it allows shorter camera exposure time, namely faster mapping.

See ISO 24173:2009, 5.3.1.

7.1.3? Magnification? observation

Depending on the observation’s purpose, it is recommended that the measurement area is nearly equal to the observation area because of that the effective probe diameter depends on SEM’s magnification.

The measurement area should be set to include more than about 100 grains to avoid effects of individual grains becoming too large. Therefore, the magnification should be set between 300 and 500 times in case of that the grain size (diameter) is about couple of 10 µm.

7.1.4 Working distance

The ideal working distance for EBSD is the working distance at which the brightest region of the raw EBSD pattern (i.e. without background correction) becomes nearly at the centre of the phosphor screen.

It is set at around 15 mm in general case, but it can be changed depending on each SEM/EBSD system configuration. Short working distances generally improve the spatial resolution of EBSD measurements,although additional care shall be paid to avoid collisions between the specimen and the pole-piece or the backscatter detector (if present).

See ISO 24173:2009, 5.3.2.

7.1.5 Focus

EBSD measurement will be done with a highly tilted specimen in a SEM. Therefore, the focus can vary depending on the beam position on the specimen (see ISO 24173). The dynamic focus is recommended to be used to avoid the out of focus condition at upper and lower of measurement area.

See also ISO 24173:2009, 5.3.

7.2 Setting the EBSD measurement conditions

7.2.1 Background correction

EBSD patterns generally have a bright centre and become much darker near the corners. The brightness of raw EBSD pattern images decrease seriously in the surrounding area. Background correction should be used to make the “raw” EBSD pattern image into ones with more uniform brightness across its whole area with better local contrast.

See ISO 24173:2009, 5.3.6.

7.2.2 Binning

The number of camera pixels, which form EBSD pattern image acquired through an image detector can be adjusted by binning setting. If the image size becomes smaller, it means binning is set larger. Then the time required for measurement becomes shorter, though the accuracy of orientation measurement can become lower in general. Large binning does not always get the faster measurement speed either, because of that the measurement speed is sometimes limited by the image processing speed or data transfer speed. The accuracy of orientation measurement for distinguishing about 0,5˚ orientation difference, can be acquired by setting the binning to the image size between 100 × 100 and 200 × 200 camera pixels.

See ISO 24173:2009, 5.3.4.

NOTE The binning is applicable to CCDs cameras and not applicable to CMOS cameras.

7.2.3 Pattern averaging

Quality of EBSD pattern image can be improved by averaging patterns collected more than one frame at the same measurement point. However, the pattern averaging makes the measurement speed slower a lot. For this reason, it is recommended to increase the probe current to acquire the same quality of EBSD patterns, instead of using pattern averaging. The quality of EBSD pattern is also controlled by adjusting the binning size and the gain of the image detector.

See ISO 24173:2009, 5.3.5.BS ISO 23703 pdf download.BS ISO 23703 pdf download