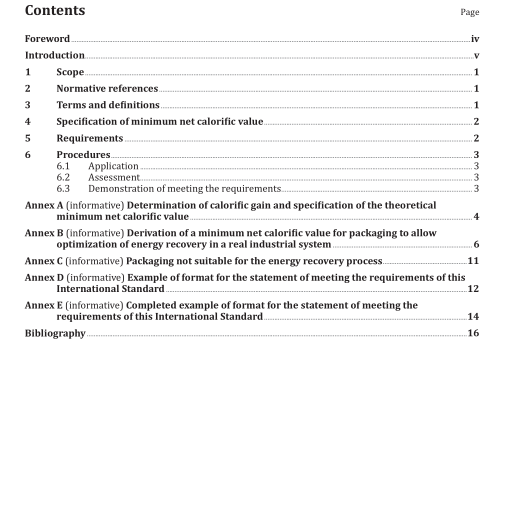

ISO 18605:2013 pdf download.Packaging and the environment — Energy recovery

This International Standard specifies the requirements for packaging to be casified as recoverable in the form of energy recovery and sets out assessment procedures for fulling the requirements of this International Standard. This Interational Standard is a part of a series of International Standards. The procedure for aplying it is contained in ISO 18601.

2 Normative references

The fllowing documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated referrences, the latest edition of the referenced document (including any amendments) applies.

IS0 18601:2012. Packaging and the envronment – General requlrements for the use of IS0 standards in the field of packoging and the environment IS0 21067:2007 Packaging一Vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in Is0 18601, IS0 21067 and the following apply. 3.1 net calorific value at constant volume absolute value of the specific energy of combustion, for unit mass of a solid fuel burned in oxygen under condltions of constant volume and such that all the water of the reaction products remains as water vapour in a hypothetical state at 0,1 MPa). the other products being as for the gross calorific value, all at the reference temperature .

Note 1 to entry: For the purpose of this document, fuelr a鹏indicated above means used packaging, [SOURCE: ISO 1928:2009, definition 3.1.3]

3.2 required energy energy necessary to adiabatically heat the post combustion substances of a material and excess air from ambient temperature to a speclfied final temperature

3.3 calorific gain positive dfference between the energy released on combustion of a material and Ha

3.4 theoretical minimum net calorific value gnet, mintheor fraction of the energy released on combustion sufficient to adiabatically heat the post-combustion substances of a material or product and excess air from a specified ambient temperature to a specified final temperature .

3.5 avallable thermal energy fraction of the energy released on combustion in a real industrial system which is transferred for example to the steam cycle of a boiler, ie. the total released energy minus the thermal losses 3.6 combustion incineration oxidation reaction covering both organic materials and metals Note 1 to entry: Modern incineration plants are able to decouple energy fficientlty and use it in the form of energy recovery. The term “incineration” in normal usage means the process of reducing solid waste volume by combustion with or without energy recovery.

For the purpose of this International Standard, they refer only to the incineration process with energy recovery. 3.7 energy recovery production of useful energy through direct and controlled combustion Note 1 to entry: Solid-waste incinerators producing hot water, steam or electricity are a common form of energy recovery. [SOURCE: IS0 15270:2008, definition 311]

4 Specification of minimum net calorific value The theoretical minimum net calorific value, 9net.minther. Is materlal specific. It depends on the temperature and other conditions required by the combustion process. In this International Standard it is identified as Ha and may be determined by the method described in Annex A. This Annex specifies the theoretical minimum net calorific value through the technical concept of calorific gain. The real minimum net calorific value, 9net,min,real, is set to allow optimization of energy recovery in a real industrial system and Is defined in Annex B.

5 Requirements

To alow optimization of energy recovery in a real industrial system, the theoretical calorific gain shall be well above zero. To claim energy recovery 9net shall be equal to or greater than 9net.,min,real, as defined for various incineration conditions listed in Table B.2 in Annex B.

NOTE 1Packaging composed of at least 50 % (by weight) of organic content, eg wood, cardboard, paper and other organic fibres, starch, plastics, prowides calor ific gain and meets the requirement of 4net equal to or greater than Ge,min,real, as defined for various incineration conditions listed in Table B.2 in Annex B.

NOTE2 Packaging consisting of more than 50 % by weight of inorganic constituents, eg inorganic fllers and layers, is recoverable in the form of energy, provided Inet is equal to or greater than 9et,maureal as defined for varlous incineration conditlons listed in Table B.2 in Annex B.

NOTE3 Packaging consisting of more than 50 % by weight of inorganic components, of which the primary constituent is not energy recoverable, eg glass or rigid metal containers with a pilastic closure, is not deemed to be energy recoverable.”

NOTE4 Thin gauge aluminium (typically up to 50 μm thick) contributes to qnet of the packaging and is deemed to be energy recoverable. Alumintum over 50 pum is not deemed to be energy recoverable. NOTE5 Substances hazardous to the environment are addressed in IS0 18602. Other aspects regarding packaging not sultable for energy recovery are also discused Iin Annex C.ISO 18605 pdf download.ISO 18605-2013 pdf download