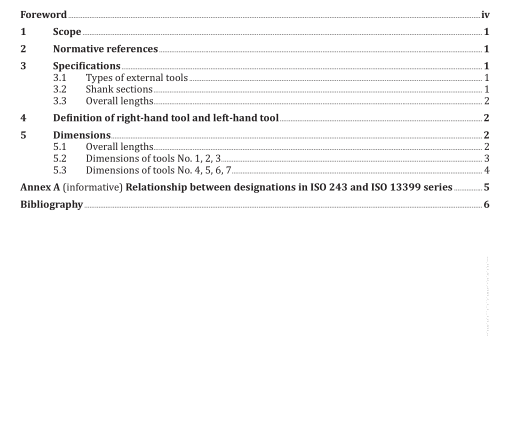

ISO 243:2014 pdf download.Turning tools with carbide tips — External tools

This International Standard specifies the types and the dimensions of turning tools with carbide tips; it deals only with external tools. It also gives the definition of right-hand and left-hand tools.

The shank sections and the inserts used are selected respectively from those defined in ISO 241 and ISO 242.

NOTE Internal tools are the subject of ISO 514; designation and marking are the subject of ISO 504.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 241, Shanks for turning and planing tools — Shapes and dimensions of the section ISO 242, Carbide tips for brazing on turning tools

3? Specifications

3.1 Types of external tools

Only seven types of tools, regarded as those most commonly used, have been retained; except for No. 4, each of these types can be provided as a left-hand or right-hand tool.

Dimension l given in Table 2 and Table 3 is the nominal length of the ISO tip. It is equal to:

b for tool No. 4;

0,8 b for tools No. 1, 2, 3, 5 and 6;

0,4 b for tool No. 7.

Dimensions n and p, the 20° angle of tool No. 1, and in particular, the cutting angle of 10°, are given for information only, but should be used unless otherwise specified, particularly in the case of tools delivered from stock.

3.2 Shank sections

For the particular case of external tools, only two types of sections are selected from among the various types provided for in ISO 241.

a) the square section h = b;

b) the rectangular section with a ratio of h/b = 1,6 approximately.

NOTE The choice between these two sections for any given tool is in accordance with the table for external tools. This choice is based on present-day techniques, but may be subject to revision in the future on the basis of studies to be undertaken by various countries with a view to establishing which type of section is best adapted to its purpose from a technical point of view.

3.3 Overall lengths

Only one range of overall lengths is specified, the length being a function of the height h of the shank,whether of square or rectangular section.

These lengths, ranged approximately in the series of preferred numbers

R 40/2 for h from 10 mm to 25 mm, and

R 40/3 for h from 32 mm to 63 mm,

are practically a linear expression in terms of h, no value departing by more than 5 mm from the minimum value obtained with the linear formula:

3,6 h + 55

4? Definition? of? right-hand? tool? and? left-hand? tool

To define whether the direction of a tool is left-hand or right-hand, it is assumed that the tool in question is mounted on its base on a vertical table, with the leading face towards the onlooker and at the bottom.

In these conditions, the tool is defined as right-hand when its cutting edge is directed towards the right of the onlooker, and as left-hand in the opposite case. See Figure 1.

5 Dimensions

5.1 Overall lengths

The overall length of the tool is a function of the height h of the shank (square or rectangular section),as given in Table 1. See Figure 2.ISO 243 pdf download.ISO 243-2014 pdf download.