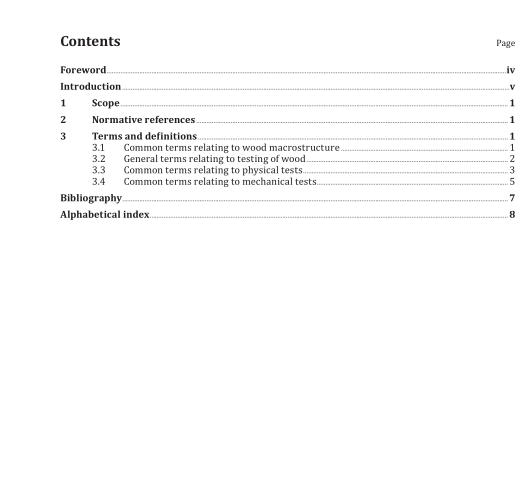

ISO 13061-18:2022 pdf download.Physical and mechanical properties of wood — Test methods for small clear wood specimens — Part 18: Vocabulary

This document lists the terms and definitions relating to general concepts, macrostructure, sampling, and methods of physical and mechanical testing of wood. Other terminologies that are not mentioned in this standard are defined in ISO 24294.

2 Normative references

There are no normative references in this document.

3? Terms? and? definitions

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1 Common terms relating to wood macrostructure

3.1.1 annual ring

growth ring (3.1.2) corresponding to an annual period of growth

[SOURCE: ISO 24294:2021, 9.9, modified — Note 1 to entry was deleted.]

3.1.1.1 annual ring width

distance, measured radially, between boundaries of adjacent annual rings (3.1.1) of wood

3.1.2 growth ring

layer of wood produced in one growing season

[SOURCE: ISO 24294:2021, 9.8, modified — Note 1 to entry was deleted.]

3.1.2.1 growth ring width

distance, measured radially, between boundaries of adjacent growth rings (3.1.2)

Note 1 to entry: The width of growth rings (3.1.2) depends on the tree species and on growing conditions. In temperate growth zones, growth rings correspond to annual rings (3.1.1).

3.1.3 juvenile wood

wood formed during the early years, found at the centre of the stem and branches, possessing physical and mechanical properties different from those of wood formed later

3.2.10 test piece

test specimen

specimen

unit or section of definite dimensions and shape intended for tests

Note 1 to entry: Usually cut from a wood piece with direction generally parallel to the grain of wood or the long

axis of a work piece sample (3.2.13).

3.2.10.1 full-size test piece

test piece (3.2.10) of identical size to the product or differing in length only

3.2.10.2 side plane of the test piece

side surface of the test piece (3.2.10)

3.2.10.3 small clear test piece

small clear test specimen

small clear wood specimen

test piece (3.2.10) of small cross-section of the clear wood (3.2.1), straight-grained wood (3.2.8)

3.2.11 transverse section

cross-section

section perpendicular to the wood grain

Note 1 to entry: Usually perpendicular to the long axis of the test piece (3.2.10).

3.2.12 working section

working part of the test piece

section of the test piece (3.2.10) where the effect of the characteristic being investigated is most important

3.2.13 workpiece sample

unit or part of products intended for preparation of test piece (3.2.10)

3.3 Common terms relating to physical tests

3.3.1 dimensional stability

ability to resist changes in dimension and volume with variation in moisture content (3.3.5)

3.3.2 density

mass per volume of a test piece (3.2.10) at a specified moisture content (3.3.5)

Note 1 to entry: Influenced by rate of growth, percentage of late wood and in individual pieces, the proportion of heartwood.

Note 2 to entry: The moisture content (3.3.5) is specified for both mass and volume.

Note 3 to entry: Usually expressed in kg/m 3 or g/cm 3 .

3.3.2.1 density in the absolutely dry condition

oven-dry density

density (3.3.2) based on oven-dry mass and oven-dry volume of a test piece (3.2.10)

[SOURCE: ISO 13061-2:2014, 3.2]

3.3.2.2 density at specified moisture content

density (3.3.2) based on mass of a test piece including moisture and its volume at the same moisture content (3.3.5)

[SOURCE: ISO 13061-2:2014, 3.3]

3.3.2.3 basic (conventional) density

density (3.3.2) based on oven-dry mass of a test piece and its green volume (3.3.4)

[SOURCE: ISO 13061-2:2014, 3.4]

3.3.4 green volume

volume of a test piece at moisture content (3.3.5) greater than or equal to the fibre saturation point before any shrinkage occurs due to drying

[SOURCE: ISO 13061-2:2014, 3.5]

3.3.5 moisture content

amount of water contained in the test piece (3.2.10), expressed as a percentage of the mass of the wood in the oven-dry state

Note 1 to entry: Determined as mass of evaporable water divided by mass of wood in oven-dry state.

Note 2 to entry: When moisture content (3.3.5) is specified for production, it is expressed as either an average moisture content with a limit on the variation, or as a moisture content limit, which a large portion of the production should not exceed.

[SOURCE: ISO 24294:2021, 6.1, modified — In the definition, “in wood” was replaced by “in the test piece”.]

3.3.6 specific gravity

relative density

ratio of the oven-dry weight of wood at a specified moisture content (3.3.5) to the weight of volume of water equal to the volume of wood

3.3.7 shrinkage

decrease in the dimensions or volume of test piece (3.2.10) due to reduction of moisture content (3.3.5) below fibre saturation point

3.3.7.1 radial shrinkage

shrinkage (3.3.7) in radial (3.2.6) direction

3.3.7.2 tangential shrinkage

shrinkage (3.3.7) in tangential (3.2.9) direction.ISO 13061-18 pdf download.