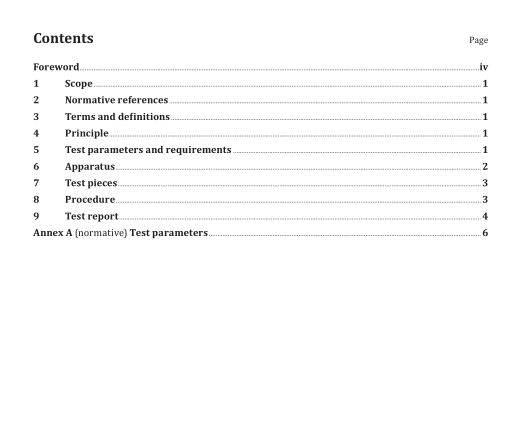

ISO 13844:2022 pdf free download.Plastics piping systems — Elastomeric-sealing-ring-type socket joints for use with plastic pipes — Test method for leaktightness under negative pressure, angular deflection and deformation

This document specifies a method for testing the leak tightness under negative pressure, angular deflection and deformation of assembled joints between elastomeric-sealing-ring-type sockets made of plastic or metal and plastic pressure pipes.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

4 Principle

A test piece consisting of a plastic pipe mounted into a socket is exposed within a specified temperature range to two specified negative internal pressures for a specified test period, while the pipe is being subjected to an angular deflection in the socket and to deformation. During the test, the test piece is monitored for signs of leakage.

5 Test parameters and requirements

The test parameters of the standard which refers to this document shall be used and the requirements shall be fulfilled. If one or more test parameters are not given in the referring standard, the ones given in Annex A shall apply.

The following test parameters should be given by the standard which refers to this document:

a) test medium;

b) test pressure (bar or MPa);

c) test duration (h);

d) test temperature (°C);

e) deformation (%);

f) angle of deflection (°);

g) free length (mm).

6 Apparatus

6.1 Framework, comprising at least two fixing devices, one of which is movable, to allow angular deflection to be applied to the test joint, while a negative air pressure (partial vacuum) is being applied.

6.2 Vacuum gauge, capable of checking conformity to the specified test pressure to within ±1 % of the measured values.

6.3 Equipment, designed to produce a deforming force on the pipe spigot at a specified distance from the mouth of the socket. A typical arrangement is shown in Figure 1.

6.4 Vacuum source (pump), capable of producing in the test piece the partial vacuum specified in the referring standard (see 8.6).

6.5 Isolation valve, between the test piece and the vacuum pump (see 8.6).

6.6 Mechanical or hydraulic device, capable of applying the necessary diametric deformation to the spigot (see 8.2) and acting on a beam which is free to move in the vertical plane square to the axis of the pipe. For pipes with a diameter equal to or greater than 400 mm, each beam may be elliptically shaped to suit the expected shape of the pipe when deformed as required. The length of the beam or the curved part of the beam shall be greater than the contact area with the deformed spigot.

The following width, b, (see Figure 1), shall depend upon the nominal outside diameter, d n , of the pipe:

— b = 100 mm for d n ≤ 710 mm;

— b = 150 mm for 710 mm < d n ≤ 1 000 mm;

— b = 200 mm for d n > 1 000 mm.

7 Test pieces

The test piece shall comprise an assembly of a plastic pipe section mounted into the socket to be tested.

The fittings and pipes shall not be tested until 24 h after their production. For practical reasons, the manufacturer may wait a shorter time before testing. In case of dispute, a duration of 24 h shall apply.

The assembly shall be carried out in accordance with the socket manufacturer’s instructions.

A pipe of the same nominal pressure (PN) or the same pipe series (S) as that of the socket shall be used for the test.

The mean outside diameter, d em , of the pipe should preferably conform to the minimum specified value, and the socket dimensions (mean inside diameter, d im , and the diameter of the groove for housing the sealing ring) should preferably conform to the maximum values stated by the manufacturer, in order to have dimensions as close as possible to the extreme limits of their relevant tolerances.

8 Procedure

8.1 Secure the socket, without any deformation, to the solid framework and align the pipe section with the axis of the socket.

8.2 Apply the deformation to the pipe in the vertical plane, as required by the referring standard,using a pair of beams (6.6) placed at a distance of 0,5 d n from the mouth of the test socket. Measure the deformation at the face of the beam adjacent to the mouth of the socket.ISO 13844 pdf download.ISO 13844 pdf download