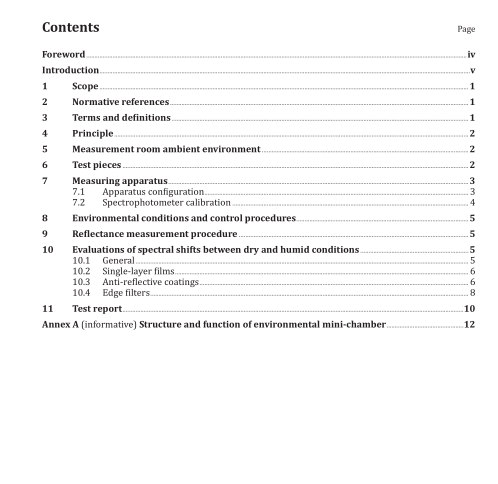

ISO 23738:2021 pdf download.Fine ceramics (advanced ceramics, advanced technical ceramics) — Measurement method of spectral reflectance of fine ceramic thin films under humid conditions

4 Principle

Fine ceramic thin films sometimes possess a voided micro columnar structure. Due to this structure, moisture in the air is adsorbed onto the surfaces of columns with voids between them.

The quantity of adsorbed water is affected by the hydrostatic vapour pressure and temperature in the environment. Depending on the quantity of water that is adsorbed, the refractive index of a thin film changes, resulting in a change in its spectral reflectance. To evaluate what effects the adsorption of water on the surface of voids in fine ceramic thin films has on the spectral reflectance of thin films, it is necessary to measure the optical properties under a vacuum, a high-humidity environment and a low-humidity environment. Comparing the results measured under a vacuum, a high-humidity environment and a low-humidity environment facilitates an evaluation of changes in the spectral reflectance due to the environmental humidity.

5 Measurement room ambient environment

The tests shall be carried out in a measurement laboratory under a room atmosphere in which the temperature and humidity changes are negligible. In particular, to prevent the condensation of water in the environmental mini-chamber, the ambient temperature shall be controlled to restrict it to a certain range.

a) Measurement room temperature: (23 ± 2) °C.

b) Measurement room relative humidity: below 70 %.

6 Test pieces

The test pieces shall comprise single-layer or multilayer thin films of fine ceramics deposited on substrates such as glass or polymer materials.

There are no restrictions on the types of materials that can be used for the substrates, provided the measurements will not be disturbed by any of the properties of the substrates. Any test piece is acceptable as long as it fits in the environmental mini- chamber in terms of its size and shape.

7 Measuring apparatus

7.1 Apparatus configuration

a) Spectrophotometer: an instrument that utilizes a double-beam method with a wavelength accuracy of ±0,2 nm or less in UV-visible light and ±1,0 nm or less in the near-infrared domain. The repeatability of the wavelength setting is ±0,1 nm or less in UV-visible light and ±0,5 nm or less in the near-infrared domain, with a desirable measurement range of 300 nm to 2 500 nm. The use of a double-beam spectrophotometer is strongly recommended. However, the use of an integrating sphere is not mandatory.

b) Environmental mini-chamber: an airtight container that maintains test pieces under a vacuum, a high-humidity environment and a low-humidity environment for the measurement of the spectral reflectance under each condition.

The chamber consists of an optical feedthrough that comprises a transparent quartz glass plate, a backside window, and two valves for the inlet of environmental air and evacuation. A test piece is fixed inside the chamber for the measurement of light reflectance. It is necessary to confirm that there is no vacuum leak from the chamber when the valves are closed. The spectrometry device configuration is shown in Figure 1. An example of the blueprint is shown in Annex A.

c) Vacuum evacuation: an exhaust equipment rotary pump or a dry pump shall be used. Any type can be used, provided the ultimate pressure is less than 40 Pa.

d) Temperature/humidity-controlled chamber: a type of chamber that allows the temperature and relative humidity to be set to 23 °C and from 40 % to 80 %, respectively. It is desirable to measure the humidity around the test pieces by using a hygrometer.

7.2 Spectrophotometer calibration Perform a wavelength and reflectance calibration for the spectrophotometer apparatus as follows:

a) Wavelength calibration: apply a test method that uses an optical glass filter.

b) Baseline correction: set the spectral reflectance to 100 % within the range of the measuring wavelength by using the baseline adjustment function of the apparatus without setting an environmental mini-chamber.ISO 23738 pdf download.ISO 23738 pdf download