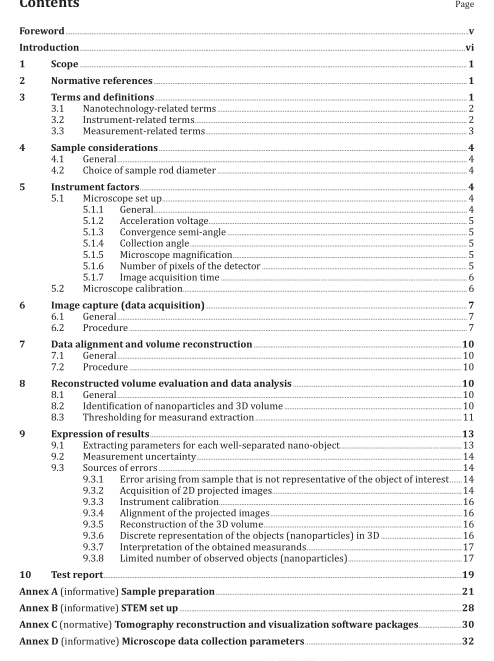

ISO TS 22292:2021 pdf download.Nanotechnologies — 3D image reconstruction of rod-supported nano- objects using transmission electron microscopy

4 Sample considerations

4.1 General

Clause 4 discusses physical properties of the sample rod. For methods that can be applied to prepare the sample rod, see Annexes A, E and F.

4.2 Choice of sample rod diameter

Sample rod diameter considerations apply to both TEM and scanning TEM (see Annex B) as follows:

a) The sample shall be rod-shaped with cross section shape no more that 50 % different from circular cross section (1:1,5 ratio of axis length for elliptical sample rod cross section);

NOTE 1 Rectangular cross-section that does not exceed the 1:1,5 aspect ratio is acceptable.

b) The sample rod shall be made of low atomic number material such as carbon;

c) The sample rod diameter shall be less than one inelastic mean free path for the incident electron energy in the TEM chosen. For example, at 300 keV incident electron energy a carbon rod with less than 250 nm diameter shall be utilized;

d) Sample rod diameter that exceeds twice the inelastic mean free path shall be avoided to reduce the effect of plural electron scattering in the sample rod and the associated loss of spatial resolution [5] [6][7] ;

e) The effect of geometrical broadening of the electron beam shall be kept at a small fraction of desired resolution of the final 3D reconstructed volume. The geometrical broadening can be estimated from instrument convergence semi-angle and collection semi-angle [1] ;

f) To ensure adequate image resolution, the sample rod diameter shall not exceed two times the depth of focus [15] .

NOTE 2 Typical imaging conditions in conventional TEM mode at 300 keV electron energy allow for about 250 nm sample rod diameter.

NOTE 3 The choice of imaging parameters for TEM and STEM tomography, depth focus, and rod diameter is described in detail in Reference [15].

5 Instrument factors

5.1 Microscope set up

5.1.1 General

This clause provides guidance on conventional parallel beam transmission electron microscope (TEM) instrumentation set up for data acquisition. For scanning TEM (STEM) instrumentation set up, see Annex B.

The critical set up parameters for TEM data acquisition are:

a) acceleration voltage (see 5.1.2);

b) convergence semi-angle (see 5.1.3);

c) collection angle (see 5.1.4);

d) microscope magnification (see 5.1.5);

e) number of pixels of the detector (see 5.1.6);

f) image acquisition time (see 5.1.7).

5.1.2 Acceleration voltage

The acceleration voltage shall be selected as described in A.2.4 d) on sample thickness. Typically, 300 kV or 200 kV should be used. Using the maximum voltage available on a particular TEM is preferred. Using the maximum available voltage means maximum allowable sample rod diameter and maximum depth of focus. For example, using 300 kV rather than 200 kV allows for 250 nm diameter carbon rod rather than 200 nm diameter rod at 200 kV.

5.1.3 Convergence semi-angle

The convergence semi-angle shall be selected so that the illumination at the sample plane is uniform over the imaged area of the sample. Furthermore, the illumination uniformity has to be such that the apparent sample focus does not visibly change over the observed area.

NOTE The illumination uniformity can be verified by performing an intensity profile across the image (e.g. diagonally from corner to corner of the image). The uniformity of the defocus value is typically not a concern and it can be verified by performing a fast Fourier transform (FFT) of sub areas of the image. For example, a 2048 × 2048 image can be divided into 256 × 256 pixels regions of interest. The image composed of absolute value of FFT can be compared among the various regions of interest to ensure that the FFT does not vary too much from region to region. An FFT that has same numbers of circular rings over an arbitrary sub-field of view is an indication that illumination is sufficiently uniform.ISO TS 22292 pdf download.ISO TS 22292 pdf download