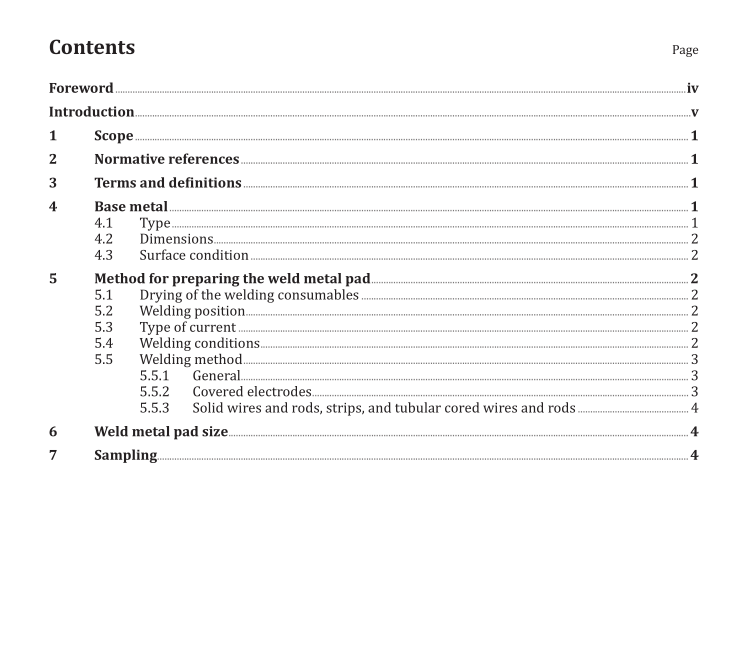

BS EN ISO 6847:2020 pdf download.Welding consumables — Deposition of a weld metal pad for chemical analysis

This document specifies the procedure to be used for deposition of a weld metal pad for chemical analysis.

This document applies to deposition of a weld metal pad by use of covered electrodes, wire electrodes for gas shielded metal arc welding, tubular cored electrodes for gas shielded metal arc welding and for non-gas shielded metal arc welding, solid rods and tubular cored rods for gas tungsten arc welding, and wire-flux and strip-flux combinations for submerged arc welding or electroslag welding and cladding.

This document is applicable to welding consumables for non-alloy and fine grain steels, high strength steels, creep-resisting steels, stainless and heat-resisting steels, nickel and nickel alloys, and copper and copper alloys.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 6947, Welding and allied processes — Welding positions

ISO 14175, Welding consumables — Gases and gas mixtures for fusion welding and allied processes

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1alloying flux

flux designed to modify the chemical composition of the weld using metals other than, or in addition to,manganese and silicon

4 Base metal

4.1 Type

The base metal (except for cladding) shall have a composition similar to that of the deposited metal or be a weldable carbon manganese structural steel with a carbon content of less than 0,2 %.

The base metal for cladding combinations shall be a weldable carbon manganese structural steel with a carbon content of less than 0,15 %, and with each of the following elements present at less than 0,10 % by weight: Cr, Mo, Nb, Ni.

4.2 Dimensions

The minimum dimensions of the base metal are given in Table 1.

4.3 Surface condition

The surface of the base metal on to which the weld metal is to be deposited shall be cleaned by grinding or other means in order to remove any rust, scale, grease, or paint.

5 Method for preparing the weld metal pad

5.1 Drying of the welding consumables

Drying of the welding consumables (covered electrodes, fluxes for submerged arc welding or electroslag welding) shall be performed using conditions indicated by the manufacturer. Tubular cored electrodes on metal supports may be dried in accordance with the manufacturer’s recommendations.

5.2 Welding position

The weld metal pad shall be welded in the flat position (PA position) in accordance with ISO 6947.

5.3 Type of current

The weld metal shall be deposited using the type of current (and, if appropriate, the polarity) indicated by the manufacturer. However, if both DC operation and AC operation are claimed, then the test shall be performed using AC.

5.4 Welding conditions

The welding conditions used, such as current, voltage, welding speed, etc., shall be in accordance with the limits specified in the relevant standard. If the welding conditions are not specified in the relevant standard, each pass shall be welded with a welding current of 70 % to 90 % of the maximum current indicated by the manufacturer. The welding conditions used to produce the weld metal pad shall be reported.

5.5 Welding method

5.5.1 General

Various methods for building up a weld metal pad have been shown to be acceptable and the weld metal pad shall be prepared using one of the methods shown in Figure 1. After the welding of each pass, the test piece may be cooled in water for about 30 s, then dried sufficiently before proceeding with the next pass. The slag shall be removed from each pass. The welding shall be performed by alternating the direction of welding for each layer.BS EN ISO 6847 pdf download.BS EN ISO 6847 pdf download