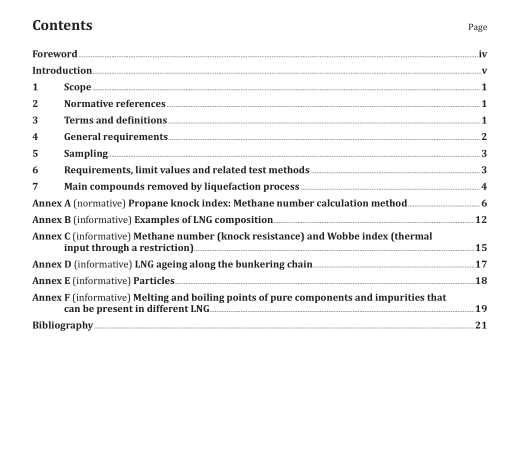

ISO 23306:2020 pdf download.Specification of liquefied natural gas as a fuel for marine applications (ISO 23306:2020)

4 General requirements

4.1 The LNG at the delivery point shall conform with the characteristics and limits given in Table 1 when tested in accordance with the specified methods.

The components listed in Table 1 and Table 2 shall be measured to enable the calculation of the physical properties of the LNG at the delivery point.

4.2 The LNG delivered shall be free from any material at a concentration that causes the LNG to be unacceptable for use, i.e. material not at a concentration that is harmful to personnel, jeopardizes the safety of the ship, or adversely affects the performance of the machinery.

4.3 Physicochemical characteristics not requiring measurement are listed in Table 3.

It is not practical to require detailed chemical analysis for each delivery of fuels beyond the requirements listed in Table 1 or Table 2. Instead, a liquefaction plant, LNG terminal or any other supply facility, including supply barges and truck deliveries, shall have in place adequate quality assurance and management of change procedures to ensure that the resultant LNG is in conformance with the requirements of this document.

Examples of LNG compositions are given in Annex B.

Information on ageing of LNG can be found in Annex D and information on particles can be found in Annex E.

4.4 The reference conditions shall be 288,15 K, 101,325 kPa (see ISO 13443:1996, Clause 3) in the gaseous phase.

5 Sampling

Samples for quality verification are not mandatory but can be taken at various locations as agreed among the parties concerned. Samples, if any, can also be taken at multiple moments in time, as LNG has distinct different ageing characteristics than traditional hydrocarbon maritime fuels (with regards to ageing reference is made to Annex D). In order to ensure a representative sample, proper sampling procedures should be followed.

When sampling of LNG for analysis is carried out, it shall be in accordance with the procedures provided in ISO 8943 or an equivalent national standard agreed between the parties concerned. Where specific sampling requirements are documented, the relevant parties should agree on the reference test methods. The LNG collected in liquid state shall be instantly conditioned to gaseous state without any partial vaporization or loss of molecular components to ensure a representative sample.

There are two methods for sampling LNG as defined in ISO 8943, continuous and intermittent. Both methods obtain LNG from the LNG cargo/bunker line and then it is gasified in a vaporizer. The continuous method collects the gasified LNG in a sample holder at a constant flow rate for offline analysis. The intermittent method collects gasified LNG and directs it to an on-line analyzer at predetermined intervals. Please refer to ISO 8943 for more details on these methods.

The requirements for sampling LNG for marine applications can vary throughout the industry,depending on availability and equipment. Load port samples can be used for quality determination if the sampling equipment is not available and if it is agreed between the parties.

6 Requirements, limit values and related test methods

The components and physicochemical characteristics that shall be measured or calculated using the related test methods are given in Table 1 and Table 2.

NOTE Information can be found in ISO 6975 [1] .

Information on MN and Wobbe index can be found in Annex C.

The fuel supplier shall calculate the actual MN at the delivery point and provide this information to the user (see Clause 5 for sampling location). This information shall be given as MN (PKI) or MN (EN 16726) .

For guidance on the MN applicability to a specific application, Original Equipment Manufacturer (OEM) specifications should be considered.

7 Main compounds removed by liquefaction process

Natural gas is liquid at around −160 °C under atmospheric pressure and becomes Liquefied Natural Gas (LNG). To avoid freezing and plugging in the liquefaction plant’s cryogenic heat exchangers,usual impurities or compounds that are present in the natural gas from various sources are removed upstream from the liquefaction process below their solubility level. Some LNG components (e.g. ethane,propane, butane and pentane) are possibly removed for commercial reasons or to achieve a targeted calorific value range.ISO 23306 pdf download.ISO 23306 pdf download