BS EN ISO 3501-2022 pdf download.Plastics piping systems — Mechanical joints between fittings and pressure pipes — Test method for resistance to pull- out under constant longitudinal force

This document specifies a method for checking the ability of assembled uniaxial joints between fittings and plastic pressure pipes to withstand longitudinal tensile stresses. The test applies regardless of the design and material of the fitting used for jointing plastics pipe.

This test method is not applicable to fusion-welded joints.

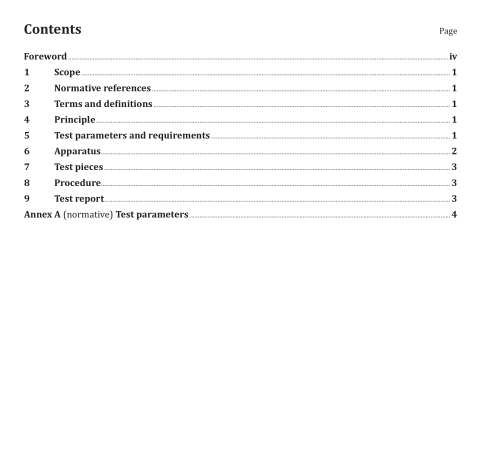

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3126, Plastics piping systems — Plastics components — Determination of dimensions

ISO 17456:2006, Plastics piping systems — Multilayer pipes — Determination of long-term strength 3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

4 Principle

An assembled joint is subjected to a longitudinal tensile force calculated as a function of the pipe dimensions and the maximum permissible induced hoop stress of the relevant pipe.

5 Test parameters and requirements

The test parameters of the standard which refers to this document shall be used and the requirements shall be fulfilled. If one or more parameters are not given in the referring document, the ones given in Annex A shall apply.

The following test parameters should be given by the standard which refers to this document:

a) pull-out force (N);

7 Test pieces

The test specimen shall consist of one or more joints formed by the assembly of at least one fitting and one or more pieces of plastic pressure pipe of the size and quality for which the fitting is designed.

The fittings and pipes shall not be tested until 24 h after their production. For practical reasons, the manufacturer can wait a shorter time before testing. In case of dispute, a duration of 24 h shall apply.

The assembly of the joint should be carried out in accordance with the manufacturer’s instructions.

8 Procedure

Determine the mean wall thickness of the pipe, according to ISO 3126. Secure the test specimen in the apparatus. Apply the calculated force gradually over a period of 30 s. Hold the specimen in constant tension for the specified test period.

Inspect the joint(s) for, and record any, indications of loosening of the joint or partial or complete separation from the fitting by pull-out.

9 Test report

The test report shall include the following information:

a) a reference to this document (ISO 3501:2021) and to the referring standard;

b) the nominal pressure class or S series of the components [e.g. fitting(s), pipe] comprising the joint(s) under test;

c) all details necessary for identification of the test pieces, including the nominal size of the pipes and fittings used to produce the test pieces, the type of material and the manufacturer’s code;

d) the test period;

e) the test temperature;

f) the calculated force;

g) the pipe free length (l 0 );

h) information on the loosening of the joint or partial or complete separation of the joint by pull-out;i) any factors which might have affected the results, such as any incidents or any operating details

not specified in this document;

j) the date of test.BS EN ISO 3501 pdf download.BS EN ISO 3501 pdf download