BS ISO 4708:2015 pdf download.Composition cork — Gasket material — Test methods

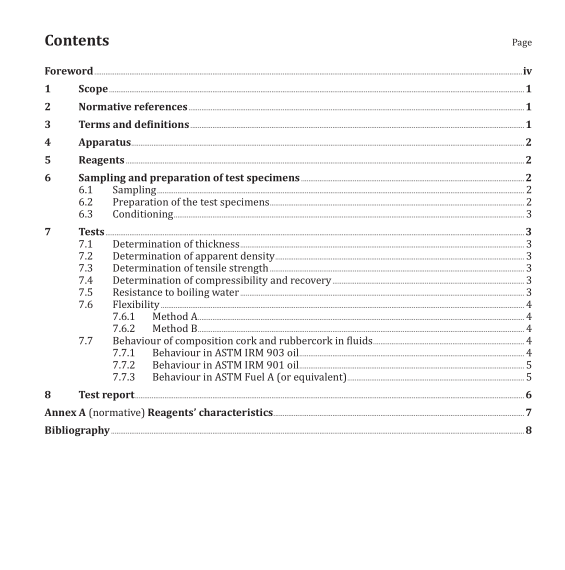

7 Tests

7.1 Determination of thickness

Determine the thickness in accordance with ISO 7322:2014, 6.1.

7.2 Determination of apparent density

Determine the apparent density in accordance with ISO 7322:2014, 6.2.

7.3 Determination of tensile strength

Determine the tensile strength in accordance with ISO 7322:2014 6.3.

7.4 Determination of compressibility and recovery

Determine the compressibility and recovery in accordance with ISO 7322:2014, 6.4.

The dimensions of the test specimens are specified in Table 1. The test specimens shall consist of a single ply or a number of superimposed plies to give a minimum test thickness of 3,2 mm.

Results obtained for test specimens outside this test thickness shall be regarded as merely indicative.

For specification purposes, agreement on compressibility and recovery values shall be reached between the interested parties for those materials whose thickness, in a single ply or multiple plies, does not fall within the nominal thickness specified.

7.5 Resistance to boiling water

Determine the resistance to boiling water in accordance with ISO 7322:2014, 6.5.

7.6 Flexibility

7.6.1 Method A

7.6.1.1 Procedure

Firmly hold the test specimen at one point on a circular mandrel (4.1) and slowly but firmly, under finger pressure, force the test specimen to contact 180° of the full mandrel diameter for approximately (5 ± 1) s. Repeat this flexure using decreasing mandrel diameters on new test specimens until failure (3.3) occurs.

7.6.1.2 Calculation and expression of results

The test result is the minimum diameter, expressed in millimetres, on which the test specimen could be flexed without any signs of failure (3.3).

A flexibility factor may be calculated by dividing this minimum diameter by the nominal thickness of the test specimen.

7.6.2 Method B

7.6.2.1 Procedure

Place the test specimens in the oven (4.2) set at (100 ± 2) °C, for 70 h. After this period, remove the test specimens, allow them cool for (24 ± 1) h under laboratory ambient conditions. Carry out the test as specified in 7.6.1.1.

7.6.2.2 Calculation and expression of results

The test result is the minimum diameter, expressed in millimetres, on which the test specimen could be flexed without any signs of failure (3.3).

7.7 Behaviour of composition cork and rubbercork in fluids

These test methods provide a standardized procedure to measure the effect of immersion in specified fluids under definite conditions of time and temperature. The test results are not intended to give any direct correlation with service conditions, taking into account the wide variations in temperature and special use that may be found in gasket applications. The specific test fluids and test conditions outlined were selected as typical for purposes of comparing different materials and may be used as a routine test when agreed between the interested parties.

7.7.1 Behaviour in ASTM IRM 903 oil

7.7.1.1 Procedure

The test specimens shall have the dimensions defined in Table 1 and the material thickness defined in Table 2. The test specimens shall be conditioned before the test as specified in 6.3.

Determine the thickness of the test specimens as specified in 7.1.

Place the test specimens in the containers (4.3) with ASTM IRM 903 oil (or equivalent), for 72 h, at ambient temperature (between 22 °C and 30 °C). At the end of this period, remove the test specimens,clean them with absorbent paper (4.5) and determine the new thickness of the test specimens.

7.7.2 Behaviour in ASTM IRM 901 oil

7.7.2.1 Procedure

The test specimens shall have the dimensions specified in Table 1 and the material thickness specified in Table 2. The test specimens shall be conditioned before the test as specified in 6.3.

Determine the thickness of the test specimen as specified in 7.1.

Place the test specimens in the containers (4.3) with ASTM IRM 901 oil (or equivalent), ensuring that the test specimens are separated from each other and from the bottom of the container and remain immersed in the test fluid. Cover the containers with aluminium foil (4.6) and place the containers for (70 ± 2) h in the oven (4.2) set at 100 °C.

After this period, remove the test specimens from the containers and immediately immerse them in a cool fresh portion of the test fluid, for 30 min to 60 min at ambient temperature (between 22 °C and 30 °C). Remove the test specimens from the containers, clean them with absorbent paper (4.5) and determine the new thickness of the test specimens.BS ISO 4708 pdf download.BS ISO 4708 pdf download