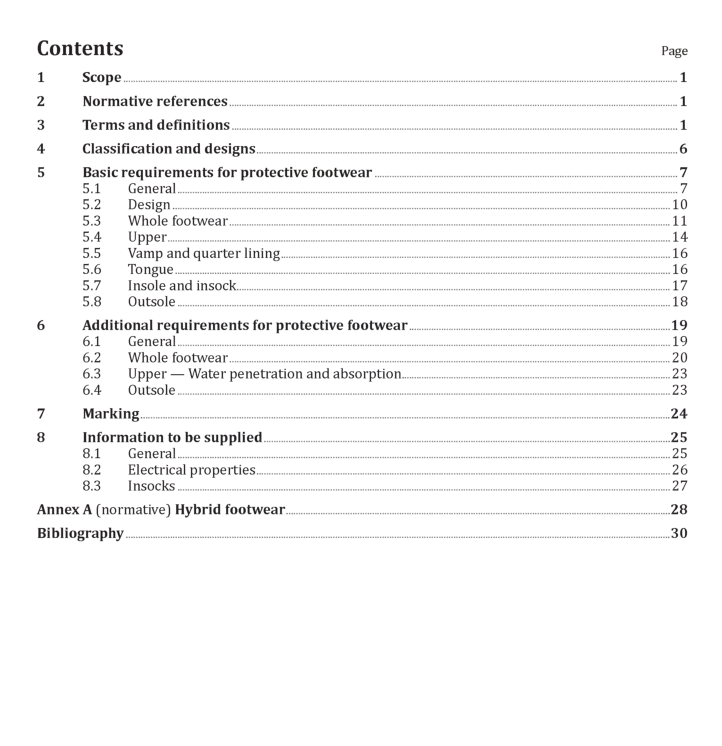

BS EN ISO 20346:2014 pdf download.Personal protective equipment — Protective footwear

This International Standard specifies basic and additional (optional) requirements for protective footwear used for general purpose. It includes, for example, mechanical risks, slip resistance, thermal risks, ergonomic behaviour.

Special risks are covered by complementary job-related standards (e.g. footwear for firefighters,electrical insulating footwear, protection against chain saw injuries, protection against chemicals and molten metal splash, protection for motor cycle riders).

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 17075, Leather — Chemical tests — Determination of chromiu

ISO 20344:2011, — Tes

EN 12568:2010, Foot and leg protectors — Requirements and test methods for toecaps and penetration resistant inserts

EN50321, Electrically insulating footwear for working on low voltage installations

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

NOTE The component parts of footwear are illustrated in Figures 1. 2 and 3.

3.1 protective footwear

footwear incorporating protective features to protect the wearer from injuries that could arise through accidents

Note 1 to entry: Items of protective footwear are fitted with toecaps designed to give protection against impact when tested at an energy level of at least 100 J and against compression when tested at a compression load of at least 10 kN.

3.2 leather

hide or skin tanned to be imputrescible

3.2.1 leather split

flesh or middle part of a hide or skin, obtained by splitting a thick leather, which is tanned to be imputrescible

3.3 rubber

vulcanized elastomers

3.4 polymeric materlals

iarge molecules composed of repeating structural units (monomers) typically connected by chemical bond

EXAMPLE Polyurethane (PU] or polyvinylchloride (PVC) .

3.5 insole

non-removable component used to form the base of the shoe to which the upper is usually attached

during lasting

3.6 insock

removable or non-removable footwear component used to cover part or all of the insole

Note 1 to entry: “Non removable” means that the insock cannot be removed without being damaged.

3.7 lining

material covering the inner surface of the upper

Note 1 to entry: The wearer’s foot is in direct contact with the lining.

Note 2 to entry: Where an upper is split at the forepart to house the toecap, or if an external piece of material is

stitched to the upper to form a pocket to house the toecap. the material under the toecap acts as a lining.

3.7.1 vamp lining

material covering the inner surface of the forepart of the upper

3.7.2 quarter lining

material covering the inner surface of the quarters of the upper

3.8 cleat

protruding part of the outer surface of the sole

3.9 rigid outsole

sole which cannot be bent through an angle of 45° under a load of 30 N

Note 1 to entry: Testing is performed in accordance with Is0 203442011, 841.

3.10 cellular outsole

outsole which has a density of0,9 g/ml or less with a cellstructure that is visible under 10x magnification

3.11 penetratio

1-resistant insert

footwear component placed in the sole complex in order to provide protection against penetration

3.12 protective toecap

built-in footwear component designed to protect the toes of the wearer from impacts of an energy level of at least 100 I and compression at a load of at least 10 kN

3.13 seat region

counter area

rear 10 % of the total length of the footwear (upper and sole)

3.14 conductive footwear

footwear, the resistance of which is in the range of0 kQl to 100 kn

Note 1 to entry: Resistance is measured in accordance with IS0 20344:2011, 5.10.

3.15 antistatic footwear

footwear, the resistance of which is above 100 kd and less than or equal to 1 000 MO

Note 1 to entry: Resistance is measured in accordance with IS0 20344:2011, 5.10.

3.16 electrically insulating footwear

footwear which protects the wearer against electrical shocks by preventing the passage of dangerous current through the body via the feet

3.17 fuel oil

aliphatic hydrocarbon constituent of petroleum

3.18 specific job-related footwear

safety or occupational footwear relating to a specific profession EXAMPLE

Footwear for firefighters; footwear with resistance to chain saw cutting.

3.19 hybrid footwear

class II footwear incorporating another materlal which extends the upper

Note 1 to entry: See Figure A.1.BS EN ISO 20346 pdf download.BS EN ISO 20346 pdf download