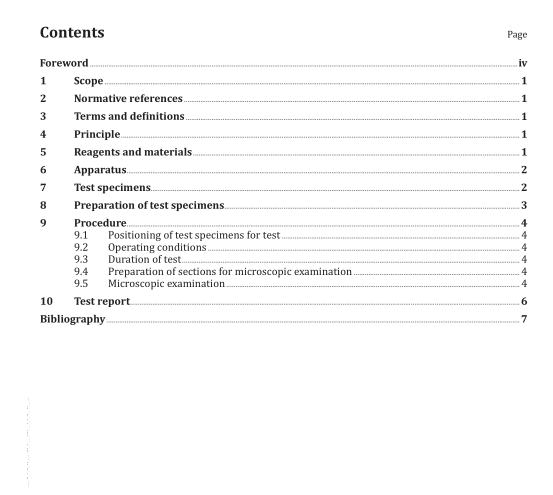

ISO 6509-1:2014 pdf download.Corrosion of metals and alloys — Determination of dezincification resistance of copper alloys with zinc — Part 1: Test method

9 Procedure

9.1 Positioning of test specimens for test The test specimens shall be placed in the beaker (6.1) containing the copper (II) chloride solution (5.1) so that the test surfaces are vertical and at least 15 mm above the bottom of the beaker. The plastic foil shall then be placed over the beaker and secured (see Figure 1). NOTE 250 ml − + 10 50 ml of the copper (II) chloride solution are required per 100 mm 2 of exposed surface of the test pieces. 9.2 Operating conditions

9.2.1 The beaker containing the test specimens shall be placed in the thermostatically controlled environment (6.2), the temperature of which shall be maintained at 75 °C ± 5 °C during the entire exposure period.

9.2.2 Different alloys shall not be tested simultaneously in the same beaker.

9.3 Duration of test The test specimens shall be exposed continuously for 24 h ± 30 min. At the end of this period, they shall be removed from the beaker, washed in water (5.2), rinsed in an appropriate solvent (5.4) and allowed to dry.

9.4 Preparation of sections for microscopic examination Microscopic examination of the test specimens shall be carried out as soon as possible after exposure. If the test specimens are stored before microscopic examination, they shall be kept in a desiccator. Each test specimen shall be sectioned at right angles to the exposed test surface. The section shall be ground and polished for microscope examination. The total length of the section through the exposed surface shall be not less than 5 mm. If the dimensions of the test specimen make this impossible, the section shall be taken to provide the maximum possible total length.

9.5 Microscopic examination

9.5.1 The micro-section prepared from each test area shall be examined using an optical microscope provided with a scale for measurement of the dezincification depth (6.3) and the maximum as well as the average depth of dezincification with respect to the final, corroded, surface shall be recorded. The appropriate magnification shall be used to provide the greatest accuracy of measurement.

9.5.2 For some purposes, assessment of the characteristics of dezincification distribution, for example whether the depth of the dezincified zone varies greatly (localized dezincification) or is an extended area (layer dezincification) and whether the attack is limited to a single phase in the alloy, measurements of both the average and the maximum depth of dezincification shall be executed. In the case of a few localized dezincification attacks, only the measurement of the maximum depth of attack is required. The importance of measurement of both maximum and average dezincification depth is demonstrated in Figure 3.

9.5.3 The examined section shall have the maximum possible length. If there is evidence of edge effects, for example a greater depth of dezincification along the line of the interface between the mounting material and the specimen, the maximum depth of dezincification shall be measured at a sufficient distance from the interface to render such edge effects negligible.

9.5.4 Using the measuring scale incorporated in the microscope, measure and record the dezincification depth, i.e. the point of intersection of the scale and the dezincification front [see Figure 4 a)], for each contiguous field. If the scale lies between two dezincified areas within the visual field, the dezincification depth shall be recorded as the point of intersection of the scale and an imaginary line joining the extremities of the two dezincification fronts adjacent to the scale [see Figure 4 b)]. If there is no evidence of dezincification in the field examined, or only one dezincified area which does not intersect the scale, then record the dezincification depth of that field as zero [see Figure 4 c)].

NOTE To ensure the best accuracy of measurement, measure the largest number of contiguous fields at the greatest possible magnification.

9.5.5 After measurement of all the contiguous fields along the entire length of the section for evaluation, calculate and report the mean dezincification depth as the sum of the measured depth for every field, divided by the number of contiguous fields examined.ISO 6509-1 pdf download.ISO 6509-1 pdf download