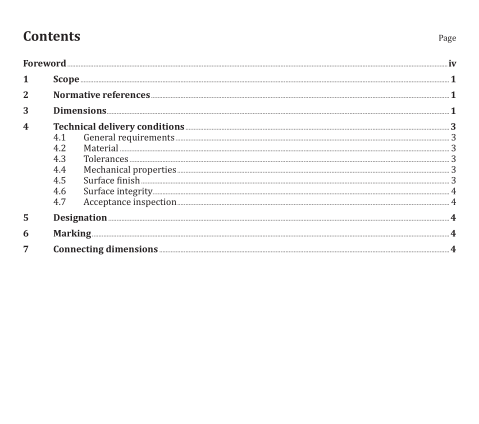

ISO 21670:2014 pdf download.Fasteners — Hexagon weld nuts with flange

This International Standard specifies characteristics for hexagon weld nuts with flange, with sizes M5 to M16 (coarse thread) or D = 8 mm to 16 mm (fine pitch thread), of product grade A.

Weld nuts conforming to this International Standard are suitable for use with bolts of property classes up to 10.9 according to ISO 898-1.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 724, ISO general-purpose metric screw threads — Basic dimensions

ISO 898-1, Mechanical properties of fasteners made of carbon steel and alloy steel — Part 1: Bolts, screws and studs with specified property classes — Coarse thread and fine pitch thread

ISO 898-2, Mechanical properties of fasteners made of carbon steel and alloy steel — Part 2: Nuts with specified property classes — Coarse thread and fine pitch thread

ISO 965-3, ISO general purpose metric screw threads — Tolerances — Part 3: Deviations for constructional screw threads

ISO 3269, Fasteners — Acceptance inspection

ISO 4759-1, Tolerances for fasteners — Part 1: Bolts, screws, studs and nuts — Product grades A, B and C

ISO 6157-2, Fasteners — Surface discontinuities — Part 2: Nuts

ISO 8992, Fasteners — General requirements for bolts, screws, studs and nuts

3 Dimensions

Nut dimensions shall be as given in Figure 1 and Table 1.

4 Technical delivery conditions

4.1 General requirements

General requirements are specified in ISO 8992.

4.2 Material

Weld nuts with flange shall be made of steel with a maximum carbon content of 0,25 % having a carbo equivalent content CEV of maximum 0,53 % (mass fraction) determined as follows:

If quenching and tempering of the nuts is required, the hardness shall not exceed 300 HV.

Use of free-cutting steel is not permissible.

If a specific steel is required, this shall be agreed on ordering.

4.3 Tolerances

Weld nuts with flange shall be of product grade A in accordance with ISO 4759-1, with threads in accordance with ISO 724, however, with tolerance class 6G in accordance with ISO 965-3.

4.4 Mechanical properties

Weld nuts according to this International Standard shall meet the proof load values as specified in Table 2. The proof load test shall be in accordance with ISO 898-2.

In case of dispute, welding projections shall be removed prior to testing.

4.5 Surface finish

Hexagon weld nuts with flange are delivered uncoated.

Since uncoated weld nuts may be affected by corrosion during transport or storage, the manufacturer shall prove corrosion protection that does not impair nut weldability.

4.6 Surface integrity

Limits for surface discontinuities are specified in ISO 6157-2.

4.7 Acceptance inspection

Acceptance inspection shall comply with the specifications given in ISO 3269.

5 Designation

EXAMPLE 1 A hexagon weld nut with flange, thread M10, made of steel, not quenched and tempered, which is suitable for use with a corresponding bolt or screw of property class 10.9, is designated as follows:

Weld nut ISO 21670 – M10 – St

If a quenched and tempered weld nut is agreed, the symbol QT shall be added to the designation.

EXAMPLE 2 A hexagon weld nut with flange, thread M12 × 1,5, made of steel, quenched and tempered, which is suitable for use with a corresponding bolt or screw of property class 10.9, is designated as follows:

Weld nut ISO 21670 – M12 × 1,5 – St – QT

6 Marking

Hexagon weld nuts with flange of size M5 or greater shall be marked with the manufacturer’s mark. The marking shall be at the nut face which is opposite to the flange.

7 Connecting dimensions

See Figure 2 and Table 3.ISO 21670 pdf download.ISO 21670 pdf download