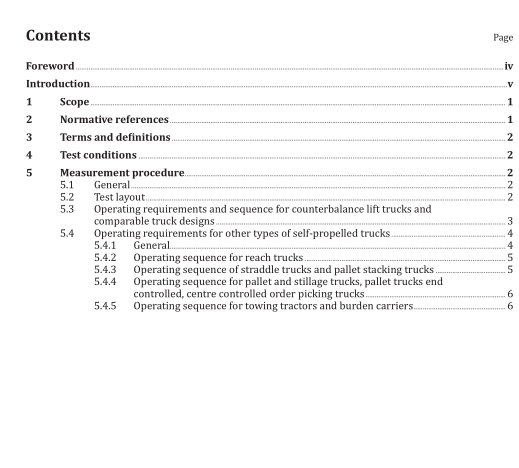

ISO 23308-2:2020 pdf download.Energy efficiency of industrial trucks — Test methods — Part 2: Operator controlled self propelled trucks, towing and burden carrier trucks

This document specifies the method of energy consumption measurement for the following types of industrial trucks as defined in ISO 5053-1:

— counterbalance lift truck;

— articulated counterbalance lift truck;

— reach truck (with retractable mast or fork arm carriage);

— straddle truck;

— pallet-stacking truck;

— pallet truck;

— platform and stillage truck;

— pallet truck end controlled;

— order-picking truck;

— centre-controlled order-picking truck;

— towing, pushing tractor and burden carrier;

— towing and stacking tractor;

— side-loading truck (one side only);

— lateral-stacking truck (both sides);

— lateral-stacking truck (three sides);

— multi-directional lift truck.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 23308-1:2020, Energy efficiency of Industrial trucks — Test methods — Part 1: General

ISO 3691-1:2011, Industrial trucks — Safety requirements and verification — Part 1: Self-propelled industrial trucks, other than driverless trucks, variable-reach trucks and burden-carrier trucks

ISO 5053-1, Industrial trucks — Terminology and classification — Part 1: Types of industrial trucks

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 5053-1 and ISO 23308-1 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

4 Test conditions

The test conditions are given in ISO 23308-1:2020, Clause 4.

5 Measurement procedure

5.1 General

ISO 23308-1 applies together with 5.2, 5.3 and 5.4, which describe specific information for the respective truck type.

5.2 Test layout

5.3 Operating requirements and sequence for counterbalance lift trucks and comparable truck designs

For counterbalance trucks, lorry-mounted trucks, multi-directional forklift trucks and articulated counterbalance lift trucks the cycle shall be performed according to Figure 1 and Table 1 and shall start at position “A”.

While travelling, the load shall be at a lift height defined by the manufacturer, typically 300 mm. The mast or the fork carriage shall be tilted to the maximum backwards tilt.

Simultaneous operation is not permissible, travelling is not permitted while lift/lowering, or tilt operations.

The test duration shall be 1 h and the speed shall be adapted to reach the number of cycles per hour as defined in Table 1. If the truck is not capable to achieve the number of cycles as specified within 1 h,the test shall be continued at maximum performance until the specified number is achieved. The time needed shall be reported in the declaration as defined in ISO 23308-1:2020, 6.2.1.

At position “B” and “D”, the load shall be lifted and lowered without depositing the load.

The sequence of the cycle shall be carried out with the following actions:

— start at position “A”;

— travel in forward direction to position “B” by turning through 90°;

— return the backward tilt to the vertical position;

— lift the load with the lift as specified in Table 1;

— lower to the lift height for travelling (300 mm);

— tilt back to maximum;

— drive backwards to position “C”;

— drive forward to position “D”;

— repeat the procedure as on position “B”;

— drive backwards to position “A”;

5.4 Operating requirements for other types of self-propelled trucks

5.4.1 General

For other truck types within the scope of this document, the cycle shall be performed according to Figure 1 and Table 2.

NOTE For types of trucks not covered by this document or other parts of the ISO 23308 series, one of the specific measurement procedures can be chosen and used as a guideline.

At position “B” and “D”, the load shall be lifted and lowered without depositing the load.

The test duration shall be 1 h and the speed shall be adapted to reach the number of cycles per hour as defined in Table 2.

Simultaneous operation is not permissible, travelling is not permitted while lift/lowering, reach or tilt operations.

While travelling, the load shall be at a lift height defined by the manufacturer, typically 300 mm.ISO 23308-2 pdf download.ISO 23308-2 pdf download