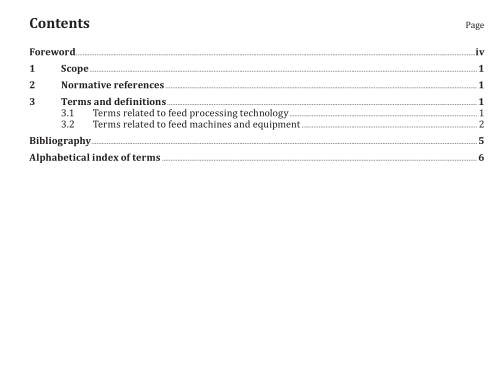

ISO 24378:2022 pdf download.Feed machinery — Vocabulary

This document defines terms related to feed processing technology, machines and equipment widely

used in feed mills.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1 Terms related to feed processing technology

3.1.1 air-assisting

using the forced air to enhance working efficiency, control dust, particle size, temperature, pressure and/or moisture

3.1.2 batching

dosing and weighing ingredients to combine them to meet the formulation requirements

3.1.3 coating

covering the surface of an intermediate product uniformly with a predetermined amount of liquid, and/or powder

3.1.4 destoning

removing stones from raw materials by specific gravity differences, using airflow and screening surfaces

3.1.5 dry mixing

mixing dry, solid ingredients without the addition of liquid ingredients

3.1.6 extruding

pressing or pushing feed through constrictions to continuously shape a feed EXAMPLE Using a machine with one or more rotating screws and die.

3.1.7 flushing

passing a predetermined amount of a specified material through a machine or a closed feed production system to clean it and reduce contamination of next feed production cycle

3.2.6 expander

machine that uses a rotating screw to continuously push feedstuff through an annular gap, active disc

system or crown

3.2.7 extruder

machine that heats up the product and propels it through the die to create the desired shape, using a

system of barrels and cylinders that create increased pressure and sudden depressurization

3.2.8 extruder die

perforated plate installed at the discharge end of the extruder (3.2.7) barrel for shaping the feed product

3.2.9 feeder

machine that regulates flow and conveys material

3.2.10 hammer mill

machine that reduces particle size by impact from rotating plates (hammers) in a chamber

Note 1 to entry: A screen (3.2.23) is used to regulate the particle size.

3.2.11

helical ribbon

spiral component attached to the main shaft in a mixer (3.2.16) used to agitate ingredients

3.2.12 high temperature and short time conditioner

HTST conditioner

machine used for the pre-treatment and conditioning of animal feed that involves high temperature and high pressure for a short period of time

EXAMPLE An expander (3.2.6).

3.2.13 liquid homogenizer

machine used to reduce particle size of liquid components and mix them uniformly

3.2.14 lump breaker

machine that breaks up large materials or conglomerates

3.2.15 magnetic separator

equipment that removes ferrous materials by magnetic attraction

3.2.16 mixer

machine that blends ingredients to homogeneous product

3.2.17 paddle

tool attached to the shaft to mix and/or convey material

3.2.18 pellet die

part used in a pellet mill (3.2.19) with hole openings through which the mixed mash feed is pressed to form pellets

Note 1 to entry: It may be mounted in different orientations and be a ring or flat.

3.2.19 pellet mill

pelletizer

pellet press

machine used to agglomerate feed by compacting and forcing it through die openings to be formed into pellets

3.2.20 pulverizer

machine used to grind small particulate with air assist

Note 1 to entry: It is typically vertical in orientation and capable of grinding up to 100 μm.

3.2.21 retentioner

machine for retaining the preconditioned mash feed for a length of time at a predetermined temperature and moisture setting

3.2.22 roller mill

grinding machine mainly comprising one or more pairs of parallel corrugated rolls rotating in opposite directions

3.2.23 screen

equipment used to separate particles by size and shape

3.2.24 working tank

tank that holds pre-adding or pre-coating liquids before the mixing or coating (3.1.2) process

Note 1 to entry: The amount held in a working tank is predetermined by operations.ISO 24378 pdf download.ISO 24378 pdf download