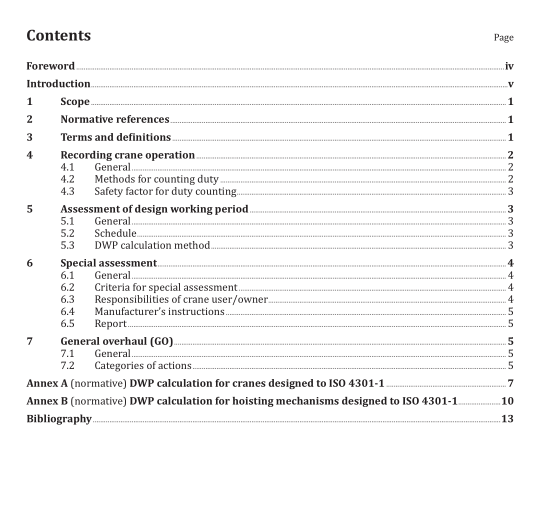

BS ISO 12482:2014 pdf download.Cranes — Monitoring for crane design working period

4 Recording crane operation

4.1 General

The crane owner should keep records of the crane use, adequate to identify the criteria specified by the crane manufacturer and applicable to carry out the assessments described in this standard. Records should also be kept of maintenance, inspections, repairs, modifications and exceptional occurrences, e.g. overloads, extreme climatic conditions and collisions. Records should be updated at least once a year during periodic inspections, see ISO 9927-1.

4.2 Methods for counting duty Estimation of the duty history can be divided into the following categories, based on systematic and reliable data collection and documentation procedures.

a) Crane operation data are recorded by a special, purpose-built system, which always operates automatically when the crane is in use. The crane operator does not have a possibility to switch off the recording system.

b) The crane is provided with counters recording the crane operation data. The user collects and documents the operation data manually from the counters.

c) The crane duty history is calculated based upon a regular process in which the crane is working. The crane is an integral part of the process. Process data are documented.

d) The crane duty history is estimated based upon a general production data of the site where the crane is working.

e) The crane duty history is incomplete.

f) The crane duty history is unknown (e.g. in the case of a second-hand crane). The duty for DWP calculation is based on estimate or assumed to be according to design classification and design life reduced using the factor f 1 from Table 1, item 5. The basic Information for counting the crane use is in all cases provided by the crane owner/user.

Where recording instruments or counters are installed, the user should regularly inspect the instruments to ensure that they are properly functioning.

4.3 Safety factor for duty counting

When calculating the design working period (DWP) of a crane, the estimated duty from the history shall be increased by a safety factor, f 1 , according to Table 1, to cover the unreliability in the duty recording and estimation.

5 Assessment of design working period

5.1 General Many components of a crane may fail because of metal fatigue, which is difficult to predict or estimate by physical inspections. Safeguarding against fatigue failure by physical inspections may be difficult due to the following:

— the safe time window for an inspection from detectable to critical crack size can be short, leading to unnecessary frequent inspections; — detecting a fatigue crack would require in many cases a full disassembly of a component;

— planning and scheduling future repairs of the crane is not possible, and non-acceptance by an inspection typically requires immediate action and possibly interruption of crane operation. The purpose of the assessment of DWP is to estimate accumulated duty of the crane and assess its remaining life. It is assumed that

— all periodic inspections scheduled for the crane have been carried out, — any damage suffered during the operation is recorded and appropriately repaired, and

— maintenance work, as well as replacement of worn parts, is carried out in accordance with the manufacturer’s instructions. 5.2 Schedule Collecting the data on the use of a crane and the assessment of DWP should be carried out in conjunction with periodic inspections (see ISO 9927-1) at 12 month intervals.

5.3 DWP calculation method

The applied DWP calculation method should follow the specification and classification of the original design standard as closely as possible. Annexes A and B give DWP calculation methods for cranes classified and designed in accordance with ISO 4301-1. The DWP calculation shall cover both the crane as a whole (structures) and the mechanisms.BS ISO 12482 pdf download.ISO 12482-2014 pdf download