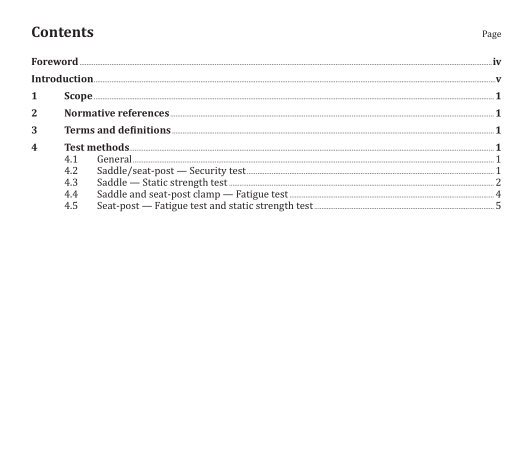

ISO 4210-9:2014 pdf download.Cycles — Safety requirements for bicycles — Part 9: Saddles and seat-post test methods

I Scope

This part of ISO 4210 specifies saddle and seat-post test methods for ISO 4210-2,

2 Normative references

the following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 4210-1, Cycles — Safety requirements for bicycles — Part 1: Terms and definitions

ISO 4210-2:2014, Cycles — Safety requirements for bicycles — Part 2: RequIrements for city and trekking, young adult, mountain and racing bicycles

1504210-3:2014, Cycles — Safety requirements for bicycles — Port 3: Common test methods

3 Terms and definitions

For the purposes of this document, the terms and definitions given In ISO 4210-1 apply.

4 Test methods

4.1 General

If a suspension seat-past is involved, the test may be conducted with the suspension system either free to operate or locked. If it is locked, the pillar shall be at its maximum length.

4.2 Saddle/seat-post — Security test

With the seat-post correctly assembled to the bicycle frame at minimum insertion depth of the seat-post (as specified in ISO 42 10-2:2014. 4.16.2), and the clamps tightened to the torque recommended by the bicycle manufacturer, apply a force ol F1 vertically downwards at a point 25 mm from either the front or rear of the saddle, whichever produces the greater torque on the saddle clamp. The saddle shall be positioned in the seat-post clamp assembly as defined by the saddle manufacturer’s rail markings or instructions. Maintain this force for 1 mm. Remove this force and apply a lateral force of F2 horizontally at -a point 25 mm from either the front or rear of the saddle and maintain this force for 1 mm, whichever produces the greater torque on the clamp (see Eigiue1). The forces are given in Table 1. The fixture shall be such that it does not damage the surface of the saddle。

4.3 Saddle — Static strength test Position the saddle in its maximum rearward direction as defined by the saddle manufacturer’s rail markings or instructions, into a suitable fixture representative of a seat-post clamp assembly. Tighten the clamps to the torque recommended by the bicycle manufacturer, and apply forces of 400 N in turn under the rear and nose of the saddle cover, as shown in Figure 2, ensuring that the force is not applied to any part of the chassis of the saddle. The load application point is on the longitudinal plane of the saddle at 25 mm from the back (front) of the saddle. If the saddle design is such that it cannot accept a centreline load application, the load shall be symmetrically applied at two points of the saddle. Loading on the rear of the saddle shall be symmetrical about its longitudinal axis, as shown in Figure 3.

4.4 Saddle and seat-post clamp — Fatigue test

4.4.1 General Seat-posts can influence test failures of saddles. For this reason, a saddle shall be tested in combination with a seat-post as recommended by the saddle manufacturer.

4.4.2 Test method Insert the seat-post to its minimum insertion depth (as specified in ISO 4210-2:2014, 4.16.2) in a rigid mount representative of that on the bicycle and with its axis at 73° to the horizontal. The saddle shall be positioned in the seat-post clamp assembly in a maximum rearward direction as defined by the saddle manufacturer’s rail markings or instructions. Adjust the saddle to have its upper surface in a horizontal plane and tighten the clamp to the torque recommended by the bicycle manufacturer. Apply a repeated, vertically-downward force of 1 000 N for 200 000 cycles, in the position shown in Figure 4, by means of a pad 300 mm long × 80 mm diameter to prevent localized damage of the saddle cover. The maximum test frequency shall be maintained as specified in ISO 4210-3:2014, 4.5.ISO 4210-9 pdf download.ISO 4210-9-2014 pdf download