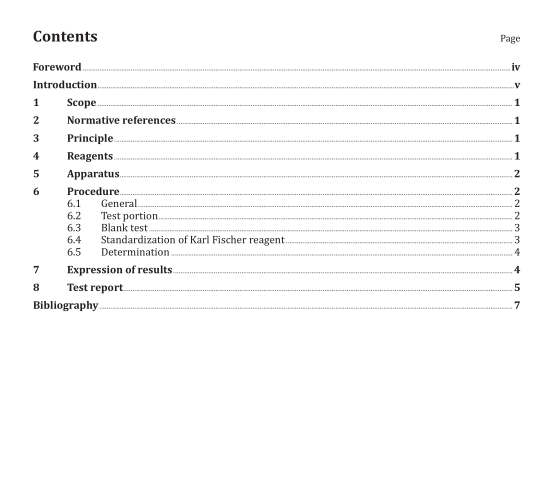

ISO 10362-2:2013 pdf download.Cigarettes — Determination of water in smoke condensates — Part 2: Karl Fischer method

6 Procedure

6.1 General

Care shall be taken during all operations to avoid contamination from atmospheric moisture. All glassware used in the preparation of the test portion and in the water determination shall be heated at (105 ± 5) °C for at least 1 h after visible water has evaporated, and cooled and stored in a desiccator over silica gel until used.

6.2 Test portion

The following procedure shall be used when cigarettes are smoked in accordance with ISO 4387. When non-standard smoking or collection of smoke condensate has been used, the procedure described below shall be modified accordingly to give a suitable smoke condensate solution.

In this event, a note of the alternative procedure shall be included with the test results. Collect the cigarette smoke condensate in accordance with ISO 4387 on a routine analytical cigarette smoking machine complying with the requirements of ISO 3308. Wearing gloves, remove the sealing devices from the smoke trap, open it and remove the filter disc with forceps. Place the folded disc in a dry conical flask (maximum 150 ml for 44 mm discs; maximum 250 ml for 92 mm discs).

Wipe the inner surface of the filter-holder front with two separate quarters of an unused conditioned filter disc and add these to the flask. Run an appropriate quantity of extraction solvent (4.1) into the flask. The folded disc shall be covered with solvent. In the case of a 44 mm glass fibre filter trap, 25 ml is necessary. In the case of a 92 mm glass fibre filter trap, 50 ml is necessary. Stopper the flask immediately and shake gently on an electric flask shaker (5.6) for at least 20 min, ensuring that the disc does not disintegrate. This provides the smoke condensate solution.

6.3 Blank test Due to the absorption of water by smoke traps and solvent, determine a value for the sample blank. Prepare sample blanks by treating additional smoke traps (at least 2 per 100 cigarettes smoked) in the same manner as that used for smoke collection. Place them near the smoking machine during smoking, and extract and analyse them together with the smoke samples.

6.4 Standardization of Karl Fischer reagent

6.4.1 Standardization procedure

Add sufficient methanol (4.3) to the Karl Fischer titration vessel (5.1) to immerse the tips of the electrodes. Titrate any residual solution (see note) in the titration vessel to its end-point by addition of Karl Fischer reagent (KFR). Using the 20 µl syringe (5.3), add 20 µl (V W ) of water to the titration vessel. To ensure that the syringe does not contain air bubbles, fill it to above the 20 µl mark, invert it and tap the air bubbles to the top. Then depress the plunger to the 20 µl mark and remove excess water quickly from the needle tip with a tissue. As an alternative, fill the syringe with 20 µl of water and weigh the syringe. After dosage, weigh the syringe again and note the exact mass of water. Transfer the volume (V W ) of water to the titration vessel taking care to inject the water directly into the solution, not allowing any to fall on to the neck or walls of the vessel.

Where the vessel can be fitted with a rubber membrane cap, this shall be used and the needle inserted through the cap. If a water droplet remains on the needle tip, remove it by touching the surface of the solution in the vessel. Titrate with KFR (4.2) and record the titration value. Repeat the process and again record the titration value. Repeat a third time. Calculate the mean titration volume (V t )· Standardize the KFR every working day.

For best results with the Karl Fischer technique, it is important to ensure that all stages of the analysis are carried out in a uniform manner, extract-to-extract, sample-to-sample, day-to-day. NOTE It is common practice with the direct-titration technique to carry out a titration “on top of” residual solution in the titration vessel, i.e. without removing the residual solution. When the volume in the vessel reaches a certain level, the liquid is run to waste, retaining just sufficient for the electrode tips to be immersed. In time, however, the methanol concentration in the vessel falls to a level such that the reaction cannot proceed satisfactorily. A precipitate may form and false titration values be obtained. Only experience will tell when titrating “on top of” residual solution has reached this point and then the titration vessel should be completely emptied to waste, rinsed, and recharged with methanol. CAUTION — Waste from the titration vessel should be run into a container which is kept stoppered until such time as safe disposal can be arranged, preferably through a waste-disposal agency, or in compliance with other national regulations.ISO 10362-2 pdf download.ISO 10362-2-2013 pdf download