ISO 11426:2014 pdf download.Jewellery — Determination of gold in gold jewellery alloys — Cupellation method (fire assay)

4.6 Pure palladium, for proof samples, minimum purity 999,5 parts per thousand (‰) by mass,free of gold.

4.7 Nickel, for proof samples, in a form of an appropriate pre-alloy (free of precious metals).

4.8 Copper (foil or wire), for proof samples, minimum purity 999 parts per thousand (‰) by mass,free of gold and platinum group metals.

4.9 Sodiumtetraborate (Na 2 B 4 O 7 ), anhydrous.

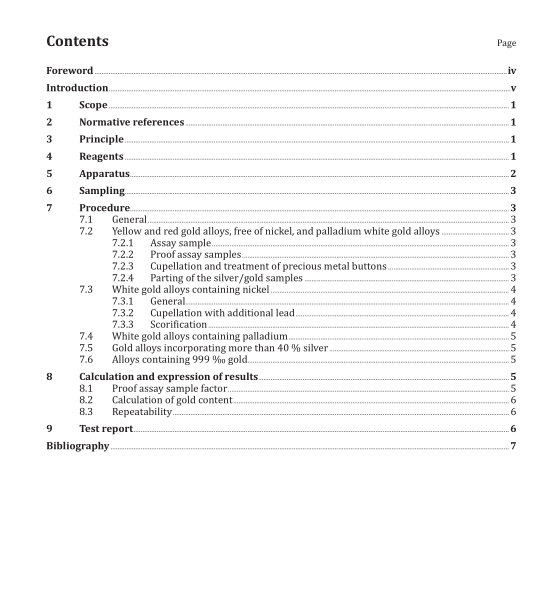

5 Apparatus

5.1 Ordinary laboratory apparatus.

5.2 Cupellation furnace, in which an oxidizing atmosphere can be maintained.

CAUTION — A standard muffle furnace is not satisfactory for this purpose.

5.3 Magnesia cupels, in form of single or block cupels, capable of absorbing the resulting lead and base metal oxides.

5.4 Parting flasks or nitric acid resistant basket, with thimbles.

5.5 Annealing crucibles, made of refractory materials.

5.6 Cupellation tongs.

5.7 Assay pliers.

5.8 Polished anvil, which may be replaced by a press, polished and reserved for this purpose.

5.9 Polished hammer, of minimum mass 400 g, which may be replaced by a press, polished, and reserved for this purpose.

5.10 Scorification dishes, usually of 50 mm in diameter.

5.11 Jewellers’ rolls.

5.12 Scorification tongs.

5.13 Assay cleaning brush.

5.14 Analytical balance, with a reading accuracy of 0,01 mg.

6 Sampling

The sampling procedure for jewellery gold alloys shall be performed in accordance with ISO 11596.

7 Procedure

WARNING — Suitable health and safety procedures should be followed.

7.1 General

When the composition of the samples is unknown, a preliminary analysis by suitable means should be used to determine the approximate composition of the material, e.g. XRF analysis.

7.2 Yellow and red gold alloys, free of nickel, and palladium white gold alloys

7.2.1 Assay sample

Transfer at least two samples of the alloy, preferably between 125 mg and 250 mg, weighed to the nearest 0,01 mg, into assay-grade lead foil (4.3). The mass of the foil (or foil and beads) should be at least 4 g for considered gold alloy samples up to 200 mg, and 6 g for samples from 201 mg to 300 mg. Add pure silver (4.4) equivalent to 2,3 to 3 times the mass of fine gold present. Roll and compress the lead foil into a tight ball.

7.2.2 Proof assay samples Weigh, as in 7.2.1, at least two proof assay samples of pure gold (4.5) and pure silver (4.4) in masses which correspond to the expected gold and silver contents (including the inquartation addition) of the assay sample. The total content of base metals in the assay samples is taken into consideration by the addition of a corresponding quantity of copper.

Treat the proof assay samples and the assay samples in 7.2.3 and 7.2.4 in the same manner. 7.2.3 Cupellation and treatment of precious metal buttons Place the assay and the proof assay samples (7.2.2), tightly wrapped in lead foil, on magnesia cupels (5.3), which have been preheated to at least 1 000 °C in the cupellation furnace (5.2). Place the cupels with the proof assay samples as close as possible to the corresponding assay samples in the cupellation furnace maintained at 1 050 °C to 1 150 °C. Continue heating (about 25 min) under oxidizing conditions until the cupellation process is completed. Remove the cupels from the furnace. Allow the precious metal buttons to cool down before lifting them from the cupels with the assay pliers (5.7). Squeeze the buttons and brush their undersides carefully with a brush (5.13) to remove any adhering cupel material. Flatten the beads on the polished anvil (5.8) with a polished hammer (5.9) and anneal by heating just to red heat. Roll them into 0,12 mm to 0,15 mm thick strips and anneal again. Roll the strips into cornets without contamination or loss of gold.

The cupel should be examined carefully to ensure that the precious metal bead contains all gold of the sample. If small droplet residues are present, a full assay has to be repeated.ISO 11426 pdf download.ISO 11426-2014 pdf download