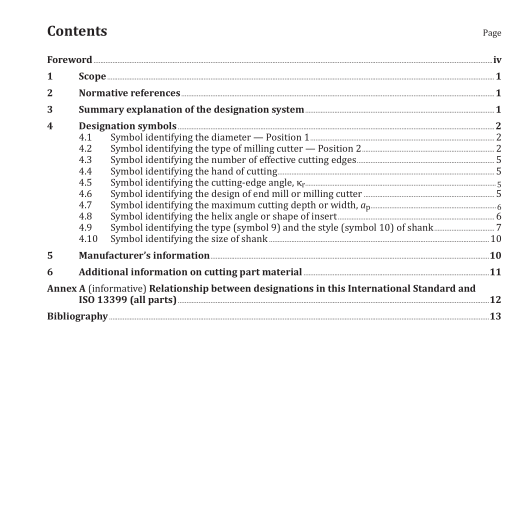

ISO 11529:2013 pdf download.Milling cutters — Designation — Shank-type and bore- type milling cutters of solid or tipped design or with indexable cutting edges

This International Standard establishes a designation system for shank-type and bore-type milling cutters of either solid or tipped design or with indexable cutting edges with the purpose of simplifying communication between the users and suppliers of such tools.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3002-1, Basic quantities in cutting and grinding — Part 1: Geometry of the active part of cutting tools — General terms, reference systems, tool and working angles, chip breakers

ISO 3002-3, Basic quantities in cutting and grinding — Part 3: Geometric and kinematic quantities in cutting 3 Summary explanation of the designation system

Shank-type and bore-type milling cutters are designated by codes comprising symbols which identify the important features of the mills.

Extensions to the designation codes to include manufacturer’s or supplier’s information about the milling cutters are described in Clause 5.

No addition to or extension of the designation system given in this International Standard shall be made without consultation with ISO/TC 29 and without its agreement. The designation code shall consist of

the following:

Position Definition of designation symbols

1 Number symbol identifying the diameter, Ø (see 4.1)

2 Letter symbol identifying the type of milling cutter (see 4.2)

3 Number symbol identifying the number of effective cutting edges (see 4.3)

4 Letter symbol identifying the hand of cutting (see 4.4)

5 Number symbol identifying the cutting-edge angle, κ r (see 4.5)

6 Letter symbol identifying the design of end mill or milling cutter (see 4.6)

7 Number symbol identifying the maximum cutting depth or width, a p (see 4.7)

8 Letter symbol identifying the helix angle or shape of insert (see 4.8)

9 Letter symbol identifying the type of shank (see 4.9)

10 Number symbol identifying the style of shank (see 4.9)

11 Number symbol identifying the size of shank (see 4.10)

EXAMPLE

Position 1 2 3 4 5 6 7 8 9 10 11

End milling cutter of solid design 32 G 04 R 090 A 012 S ZYL 10 032

Milling cutter of indexable design 250 A 12 R 075 S 075 S HSK 01 100

4 Designation symbols

4.1 Symbol identifying the diameter — Position 1

The diameter of end mills or milling cutters for each letter symbol is shown in the illustrations in Table 1.

The number symbol identifying the diameter is a one-digit to three-digit number and corresponds to the diameter, in millimetres.

EXAMPLE 1 Ø6 symbol “6”

EXAMPLE 2 Ø32 symbol “32”

EXAMPLE 3 Ø125 symbol “125

4.3 Symbol identifying the number of effective cutting edges

The number symbol identifying the number of cutting edges is a two-digit number corresponding to the number of effective cutting edges.

EXAMPLE 1 12 effective cutting edges: symbol “12”.

EXAMPLE 2 2 effective cutting edges: symbol “02”.

NOTE The number of effective cutting edges is defined as “the number of cutting edges used to calculate the feed per tooth in the direction of feed motion from which κ r is defined”.

4.5 Symbol identifying the cutting-edge angle, κ r

The number symbol identifying the cutting edge angle is a three-digit number, corresponding to the nominal cutting edge angle, in degrees, and omitting any decimals. κ r is defined for the various types of end mill in 4.2, and in ISO 3002-1, 5.1.1.1.

The three-digit number designates also milling cutters of “dove tail” design, where the cutting edge angle is larger than 90°.

EXAMPLE 1 Cutting edge angle 90°: symbol “090”.

EXAMPLE 2 Dove tail milling cutter with cutting edge angle 120°: symbol “120”.

For end mills of types K and N (see 4.2), the symbol identifying the cutting edge angle shall be replaced by 000 [triple (or treble) zero].

If end mills and milling cutters are assembled with cartridges that are carrying the cutting edges, the cutting edge angle shall be replaced by 0CA (zero, upper case letter C, upper case letter A).

If κ r is a decimal value, the symbol identifying the cutting edge angle shall be replaced by XXX, and the actual value shown as the manufacturer’s information (see Clause 5).

4.6 Symbol identifying the design of end mill or milling cutter

The symbol 6 defines either the design of the end mill or milling cutter, if it is of solid or tipped design,or the design of how the replaceable cutting edges are fixed on to the tool body.ISO 11529 pdf download.ISO 11529-2013 pdf download