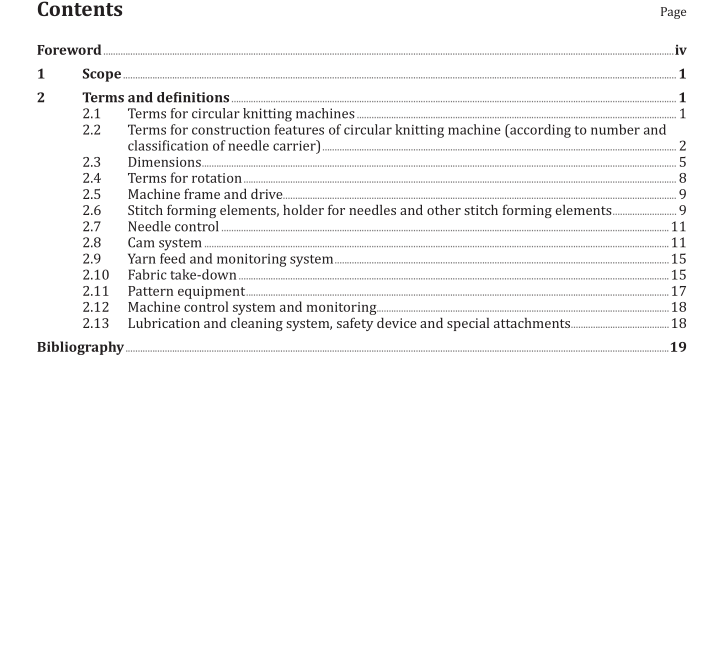

ISO 12912:2014 pdf download.Circular knitting machines — Vocabulary

This International Standard establishes a vocabulary of terms and a system of classification for circular knitting machines used in the textile industry for the production of weft-knitted fabrics.

NOTE See also the ISO online browsing platform (OBP): https://www.iso.org/obp/ui/

2 Terms and definitions

2.1 Terms for circular knitting machines

2.1.1 circular knitting machine

machine for the production of knitted fabrics with independent needles, longitudinally movable, in circular arrangement, with stitches formed one after the other within every course from yarn fed crosswise to the length of the fabric

[SOURCE: ISO 7839:2005, 2.1.2]

Note 1 to entry: The circular knitting machine can be specified more precisely with the following details:

— model (e.g. small, large);

— construction features (e.g. single jersey, double jersey, plain interlock, purl);

— needle type (e.g. latch or slide needle);

— number of feeders (e.g. 48 stitch feeders);

— patterning mechanism (e.g. jacquard unit).

2.1.2 small-diameter circular knitting machine

circular knitting machine with nominal diameter up to 165 mm

2.1.3 large-diameter circular knitting machine

circular knitting machine with nominal diameter of over 165 mm

2.2 Terms for construction features of circular knitting machine (according to number and classification of needle carrier)

2.2.1 RL circular knitting machine

circular knitting machine for the production of single-face fabrics (RL) by means of needles arranged in grooves of one carrier

[SOURCE: ISO 7839:2005, 2.1.2.1]

Note 1 to entry: See Figure 1.

2.2.2 RR circular knitting machine circular knitting machine, used mainly for the production of double-face fabrics (RR) by means of needles arranged in an axial direction in grooves of the needle cylinder and radially in grooves of the needle disc (dial) in staggered formation to one another [SOURCE: ISO 7839:2005, 2.1.2.2]

Note 1 to entry: See Figure 2.

2.2.3 interlock circular knitting machine interlock knitting machine used for the production of plain interlock fabric with needles arranged opposite each other in needle cylinder grooves in the axial direction and radial in needle disc (dial) grooves Note 1 to entry: See Figure 3.

2.2.4

LL circular knitting machine

circular knitting machine for the production of purl fabrics (LL) with two needle cylinders, one upon the other, within their grooves, which are arranged flush to each other in an axial direction, the needles moved from one needle cylinder to the other by means of a needle slider [SOURCE: ISO 7839:2005, 2.1.2.3]

Note 1 to entry: LL fabrics can contain structures like single-face fabric and/or double-face fabric, respectively can be replaced by them completely.

Note 2 to entry: See Figure 4.

2.3 Dimensions

2.3.1 machine depth

a total depth of machine without space requirement for additional equipment EXAMPLE Bobbin holders, control cabinets.

Note 1 to entry: See Figure 5.

2.3.2 machine width

b total width of machine without space requirement for additional equipment EXAMPLE Bobbin holders, control cabinets.

Note 1 to entry: See Figure 5.

2.3.3 machine height

h total height of machine without space requirement for yarn guide units

Note 1 to entry: See Figure 5.

2.4 Terms for rotation

2.4.1 direction of rotation

clockwise or anticlockwise rotation of the needle cylinder or cam casing from above

2.4.2 relative rotation

Z clockwise rotation of needle cylinder [see Figure 7 a)] or anticlockwise rotation of the cam box [see Figure 7 b)] with the courses in the fabric forming a Z (right) spiral

Note 1 to entry: The fabric is observed from outside suspended in the machine

2.5 Machine frame and drive

2.5.1 machine frame

supporting framework which carries all the other machine assemblies

2.5.2 drive

one or more units for generating the movements necessary for the stitch forming procedure and controlling the machine

2.6 Stitch forming elements, holder for needles and other stitch forming elements

2.6.1 needle cylinder

cylindrical hollow components with external grooves in axial direction for receiving and guiding the stitch forming elements

Note 1 to entry: See Figure 1.

EXAMPLE Latch needles.

2.6.2 needle disc

dial ring-shaped disc with grooves in radial direction for receiving and guiding the stitch forming elements Note 1 to entry: See Figure 2.

EXAMPLE Latch needles.

2.6.3 sinker ring

ring groove running in a radial direction for receiving and guiding holding-down, knock-over, plush,transfer and other sinkers.ISO 12912 pdf download.ISO 12912-2014 pdf download