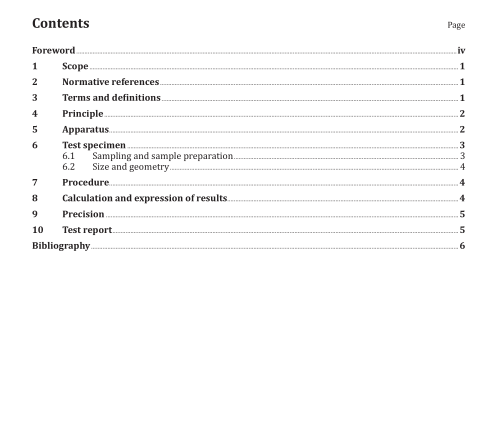

ISO 12986-1:2014 pdf download.Carbonaceous materials used in the production of aluminium — Prebaked anodes and cathode blocks — Part 1: Determination of bending/shear strength by the three-point method

This part of ISO 12986 specifies a three-point method to determine the flexural strength of carbon and solid graphite materials at room temperature.

NOTE ISO 12986 is based on DIN 51902.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 4288, Geometrical Product Specifications (GPS) — Surface texture: Profile method — Rules and procedures for the assessment of surface texture

ISO 7500-1, Metallic materials — Verification of static uniaxial testing machines — Part 1: Tension/compression testing machines — Verification and calibration of the force-measuring system

ISO 8007-1, Carbonaceous materials used in the production of aluminium — Sampling plans and sampling from individual units — Part 1: Cathode blocks

ISO 8007-2, Carbonaceous materials used in the production of aluminium — Sampling plans and sampling from individual units — Part 2: Prebaked anodes

ISO 8007-3, Carbonaceous materials used in the production of aluminium — Sampling plans and sampling from individual units — Part 3: Sidewall blocks

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 flexural strength

σ b maximum flexural stress developed in a specimen during a flexural test to rupture

Note 1 to entry: The flexural strength is calculated as the quotient of the bending moment at maximum force,before or at rupture of the specimen under the conditions of the three-point method and its section modulus.

M b is the bending moment at maximum force, in Newton millimetres;

Z is the section modulus, in cubic millimetres.

Note 2 to entry: The flexural strength is expressed in megapascals (MPa).

Note 3 to entry: Generally, the maximum force displayed on the test machine and the force at fracture are similar;

if they are different, the term refers to the maximum force displayed.

3.2 bending moment

M b component of moment of force perpendicular to the longitudinal axis of a beam or a shaft Note 1 to entry: M b is the maximum moment at fracture, calculated from the maximum force displayed by the testing machine and the geometry of the test specimen. Generally, the maximum force displayed on the test machine and the force at fracture are similar; if they are different, the term refers to the maximum force displayed.

3.3 section modulus

Z ratio of the second axial moment of area to the maximum radial distance of any point in the surface considered from the Q-axis with respect to which the second axial moment of area is defined Note 1 to entry: The section modulus can be expressed mathematically as shown in the following formula.

Z = I a /r Q,max

where

I a is the second axial moment of area;

r Q,max is the maximum radial distance considered from the Q-axis with respect to which I a is defined.

Note 2 to entry: The section modulus is calculated for the most common cross sections in Figure 2.

4 Principle

A bar-shaped test specimen is placed on two bearing blocks and a force is applied to its centre until the test specimen ruptures; the force is equally distributed on two points. The flexural strength is calculatedfrom the maximum force, the distance between the supports, and the dimensions of the cross-section of the test specimen.

5 Apparatus

5.1 Compression-testing machine, which meets at least the demands of class 2 in accordance with ISO 7500-1.

5.2 Measuring device, with two bearing blocks and one force edge.

The device shall ensure a cardanic suspension and movable support blocks; see Figure 1. The radius of curvature of the bearing blocks and of the force edges shall be in tISO 12986-1-2014 pdf downloadhe range 2 mm to 5 mm.

The distance between the points of support should be variable in order to adjust the measuring device to different sample geometries.ISO 12986-1 pdf download.