EN ISO 19679:2020 pdf download.Plastics – Determination of aerobic biodegradation of non-floating plastic materials in a seawater/sediment interface – Method by analysis of evolved carbon dioxide (ISO 19679:2020)

6.3 Natural seawater/sediment.

Take a sample of a sandy sediment and seawater with a shovel beneath the low-water line into a bucket. Transfer the wet sediment together with seawater into sealed containers for transport and fast deliver it to the laboratory. After delivery, conserve the sediment at low temperature (approximately 4 °C) until use. The seawater/sediment sample should be preferably used within 4 weeks after sampling. Record storage time and conditions.

NOTE Seawater and sediment can also be sampled from large, well-running public marine aquaria. Measure the TOC, pH and nitrogen content of the sediment and of the natural seawater if used instead of artificial seawater.

The carbon content of sediment should be in the range of 0,1 % to 2 %. A preliminary oxidation can be applied to the sediment in order to decrease the organic matter content and the background respiration. Sediment and seawater are fluxed with air and gently stirred (max. 20 r/min to 30 r/min) in a large container for the desired period of time. Include this pre- treatment process in the test report.

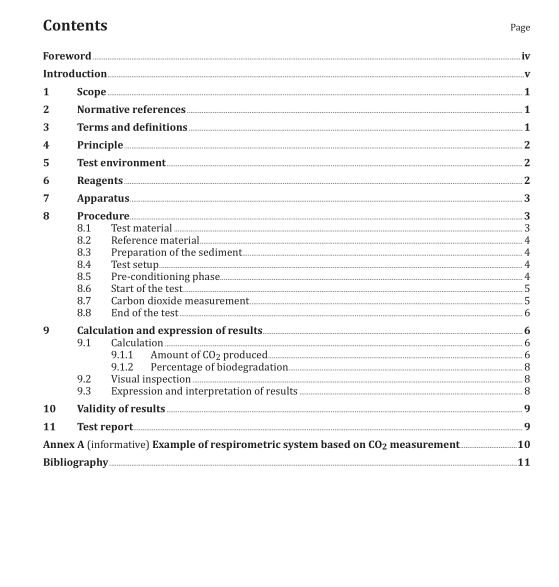

7 Apparatus

7.1 Test flasks. Biometer flasks of the volume of about 250 ml are appropriate. Reactors with higher volumes can be used, if test conditions are not affected. The vessels shall be located in a constant-temperature room or in a thermostatic apparatus (e.g. water-bath). Stirring can be applied on seawater on condition that it does not disturb the sediment/seawater interface.

NOTE A suitable apparatus is shown in Figure A.1. An example of a stirred apparatus is given in OECD TG 308: 2002, Annex 4 [7] .

7.2 Container for the CO 2 absorber. A glass beaker to be located in the headspace of the reactor and filled with 10 ml of Ba(OH) 2 0,0125 mol/l or with 3 ml of KOH 0,5 mol/l.

7.3 Analytical balance, shall have a sensitivity of at least 0,1 mg.

7.4 pH meter.

8 Procedure

8.1 Test material

The test material should be in film or sheet form. Cut samples of the test material in the shape of a disk. Disks shall have a smaller diameter than the glass flasks, so that the disks can be easily laid on the bottom of the glass flask. The sample shall be of known mass and contain sufficient carbon to yield CO 2 that can be adequately measured by the system used.

Use a test material concentration of at least 100 mg/l of seawater plus sediment. This mass of the sample should correspond to a TOC of about 60 mg/l. The maximum mass of sample per flask is limited by the oxygen supply to the glass flask. A test material concentration of 150 mg/l to 300 mg/l of seawater plus sediment is recommended.

Calculate the TOC from the chemical formula or determine it by a suitable analytical technique (e.g. elemental analysis or measurement in accordance with ISO 8245) and calculate the ThCO 2 .

The form and shape of the test material may influence its biodegradation. Similar shapes and thicknesses should preferably be used if different kinds of plastic materials are to be compared.

NOTE When the test material in form of film is laid down on the surface of the sediment, it can limit the gas exchange between the water body and the sediment, promoting the formation of anaerobic zones under the test material. In order to reduce this effect, it is possible to perforate the film sample homogeneously over the entire surface.

8.2 Reference material

Use ashless cellulose filters as a reference material 1) . If possible, the TOC, form, and size should be comparable to that of the test material. As a negative control, a non-biodegradable polymer (such as polyethylene) in the same form as the test material shall be used.

8.3 Preparation of the sediment

Filter the sediment in a funnel with a coarse filter paper to eliminate excess seawater. Sediment is ready for testing when dripping of sea water is ended. Sediment after filtering is named “wet sediment” hereafter.

8.4 Test setup

Provide several flasks, so that the test includes at least the following:

a) three flasks for the test material (symbol F T );

b) three flasks for the blank (symbol F B );

c) three flasks for reference material (symbol F C );

d) three flasks for negative control (symbol F N ).

Two flasks for test material, blank, reference material, and negative control may be used instead of three for screening purposes.EN ISO 19679 pdf download.EN ISO 19679 pdf download