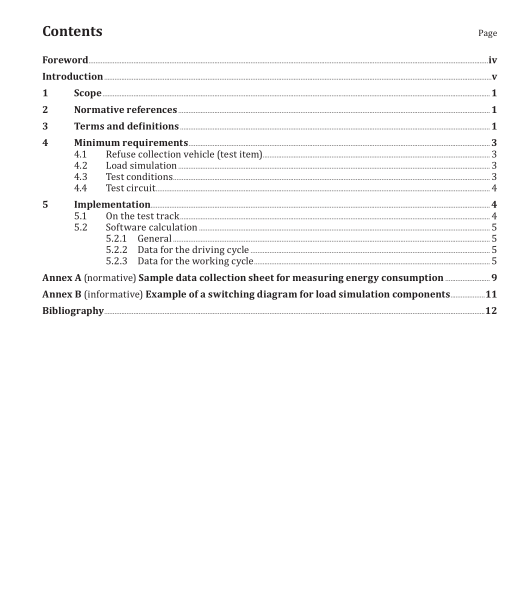

ISO 24162:2022 pdf download.Test method for energy consumption of refuse collection vehicles

4 Minimum requirements

4.1 Refuse collection vehicle (test item)

— The operating conditions shall be in accordance with the operating instructions.

— The steady state shall be achieved.

— The load simulation components shall be installed in accordance with the respective specifications

from the bodywork manufacturer.

— The vehicle configuration shall be documented in accordance with Annex A.

4.2 Load simulation

The load simulation shall be carried out hydraulically.

NOTE For an example of the installation of a hydraulic load simulation, see Annex B, Figure B.1.

4.3 Test conditions

— Temperature (°C/°F):

Range A: (10 ± 5) °C/(50 ± 9) °F;

Range B: (20 ± 5) °C/(68 ± 9) °F;

Range C: (30 ± 5) °C/(86 ± 9) °F;

Range D: (40 ± 5) °C/(104 ± 9) °F.

— Air pressure (1 013 ± 100) hPa.

— Wind speed (maximum 5 m/s).

— Dry road surface condition.

4.4 Test circuit

— The test circuit shall be a circular course.

— The road surface finish shall be asphalt or concrete.

— Gradient within the test circuit shall not exceed ± 2 %.

— Curves on the test circuit shall have a curve radius of at least 15 m.

— The stopping points shall be clearly marked, for example with traffic cones.

5 Implementation

5.1 On the test track

— The time required for a measurement run shall not exceed 60 min.

— The test should only be performed by trained personnel.

— At least three measurement runs of the same type shall be performed, taking Formula (1) into

account in order to obtain valid measurement values:

is the minimum measurement value;

M max is the maximum measurement value.

— The number of test cycles within a measurement run shall correspond to Table 4.

— The energy consumption shall be indicated for each test run in kilowatt hours (kWh), in accordance with the conversion factors in Table 5.

— To measure any energy sources, a measurement procedure according to the valid state of science and technology shall be used, such as measuring the fuel consumption using measuring turbines or comparable technologies.

— To measure the energy consumption of plug-in battery systems, only the stored energy of batteries shall be considered; the energy needed for charging the batteries is not taken into account.

— The regeneration of diesel particulate filters during the test run shall be excluded.

— In addition to energy-consuming components, such as rotating beacons and air conditioning,working lights of the vehicle shall be switched off.

— Ballasting shall be carried out in accordance with Table 1.

5.2 Software calculation

5.2.1 General

With the described method, it should be possible to achieve the same results with the software calculation as those stated in 5.1. For this it is necessary to transfer the test cycles from the test circuit to the software. This is to be performed by means of various data files which shall match the form and content with the criteria set out in Table 1 to Table 4, respectively. NOTE The data for the chassis and the common profile to drive into the collection area and return are part of VECTO, which is the official European software calculation tool.

5.2.2 Data for the driving cycle

Driving the vehicle on the test circuit from stopping point to stopping point will be illustrated by a speed curve which shall be provided both graphically and as a readable data file (by agreement with the test bench operators).

The number of test cycles shall correspond to the values in Table 4.

5.2.3 Data for the working cycle

5.2.3.1 General

The power consumption of the body shall be represented by a torque curve and an operating speed associated with this torque curve on the auxiliary drive. The duration of the working cycle shall correspond to the vehicle standstill in accordance with Table 4.

5.2.3.2 Determination of the working cycle

It is the bodywork manufacturer’s responsibility to describe the working cycle. For this purpose, the requirements according to Table 3 shall be observed. The working cycle shall proceed as follows:

— The construction test bench is equipped with a device for providing the drive capacity, generally an electrical engine. It shall be equipped with a measuring instrument for the output torque (torque measuring shaft) and a speed controller. Record the measurement values from the torque measuring shaft in a table; the working speed shall be indicated as an individual value.

— Connect the hydraulic or electric pump for the construction configuration which shall be tested to the construction test bench with the assembled and adjusted load simulation components.

— Record the measurement values at timed intervals of 0,1 s (f = 10 Hz).

— Repeat the relevant cycles for conditioning the bodywork until the steady state has been set.

— Start the measurement and repeat it 20 times for structural safety.

— Execute the test cycles in accordance with Table 2 and record the measurement values. Maintain breaks between the separate test cycles with respect to the driving times according to Table 4.

— Stop the measurement.

— Determine an average using 20 corresponding values (corresponds to the table rows) and save it in a separate table.

— Save the resulting table as the torque progression. Take this torque progression as the basis for the working cycle.ISO 24162 pdf download.ISO 24162 pdf download