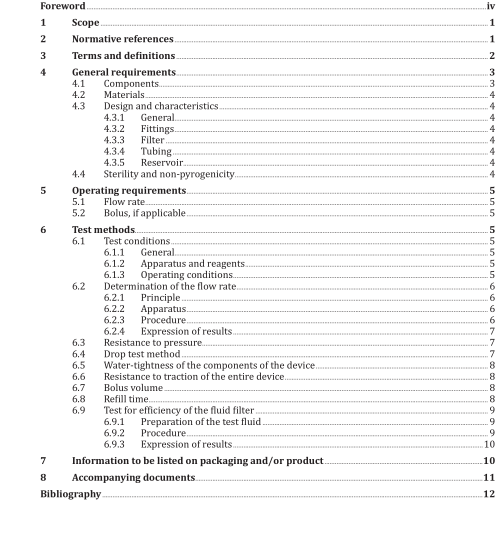

ISO 28620:2020 pdf download.Medical devices — Non-electrically driven portable infusion devices

4 General requirements

4.1 Components

The device shall contain the following components:

— means to convert non-electric energy into fluid flow;

— a flow restrictor;

— a reservoir designed to contain the solution to be administered;

— a particulate matter filter in the fluid path.

NOTE 1 These components can be integrated or delivered separately.

The device may also contain one or more of the following components (non-exhaustive list):

— a system to adjust the flow rate;

— a filling port preferably with check valve;

NOTE 2 The filling port is intended for use in the pharmacy during filling only and can be a Luer type female geometry in accordance with ISO 80369-7.

— a lock connector at the distal end of the tubing conforming to ISO 80369-6 or ISO 80369-7, as appropriate for the intended application;

— a clamp to stop the flow if necessary;

— a sterility protector, e.g. Luer cap, at the distal end of the tubing and of the filling site;

— a system to administer a bolus with a means for controlling the maximum amount of solution infused over time;

— a protective element of the reservoir, preventing the drug solution from flowing out should the reservoir break or leak (which can be necessary to fulfil the leakage test in 6.4 and 6.5);

— a means of indicating the end of infusion;

NOTE 3 This can be achieved by a visual, audible or other indication.

— administration tubing;

— an air-eliminating feature.

4.2 Materials

The materials used in the manufacture of the parts that come in contact with the drug solution shall have undergone a biological evaluation in accordance with ISO 10993-1.

4.3 Design and characteristics

4.3.1 General

The device shall be designed to deliver according to its nominal flow rate (see 5.1).

4.3.2 Fittings

If applicable, the fitting at the filling port shall be a female lock connector conforming to ISO 80369-6 or ISO 80369-7.

If fittings at the distal end of the tubing are used, they shall be male lock connectors conforming to ISO 80369-6 or ISO 80369-7, as appropriate for the intended application.

All device fittings designed to be connected to other medical devices or accessories shall conform to ISO 80369-1, ISO 80369-6 or ISO 80369-7, as appropriate for the intended application.

4.3.3 Filter

The system shall include a particulate matter filter on the fluid path of the solution.

When tested in accordance with 6.9, the retention of latex particles on the filter shall be not less than 80 %.

4.3.4 Tubing

If the device is designed with tubing, it can be fixed or removable. If the tubing is removable, the connection system to the device shall use a lock connector when tested in accordance with 6.6.

The junction between the reservoir and the tubing shall resist a static traction of 15 N for 15 s.

4.3.5 Reservoir

All elements of the device designed to receive the drug shall constitute a closed, water-tight system.

This requirement shall be verified by tests in accordance with 6.3, 6.4, 6.5 and 6.6.

If necessary, a redundant mechanism of the reservoir shall be available, minimizing the risk of leakage of the solution from the reservoir.

The reservoir of the device shall be designed so as to allow a visual inspection of the solution.

4.4 Sterility and non-pyrogenicity

All parts of the device in contact with the drug solution shall have been subjected to a validated sterilization process, shall be delivered sterile and non-pyrogenic, and shall be for single use only.

5 Operating requirements

5.1 Flow rate

Each nominal flow rate of the device shall be checked using control solutions at a given temperature.

The nominal flow rate, the control solutions and the temperatures shall be specified in the instructions for use accompanying the device [see Clause 8 c) and g)].

The mean flow rate shall have a tolerance of ±15 % compared to the nominal flow rate. The adjustable flow rate shall have a tolerance of ±20 %. At least 80 % of the nominal volume shall be delivered at an instantaneous flow rate within ±50 % of the nominal flow rate. These requirements shall be verified using the test methods described in Clause 6.

NOTE The instantaneous flow rate can deviate by more than 50 % of the nominal flow rate if the device is exposed to external pressure.

5.2 Bolus, if applicable

The bolus volume shall be not more than 115 % of the nominal bolus volume (see 6.7).

When the bolus device is activated after the nominal bolus refill time, the bolus volume shall be in the range of 50 % to 115 % of the nominal bolus volume.ISO 28620 pdf download.ISO 28620 pdf download