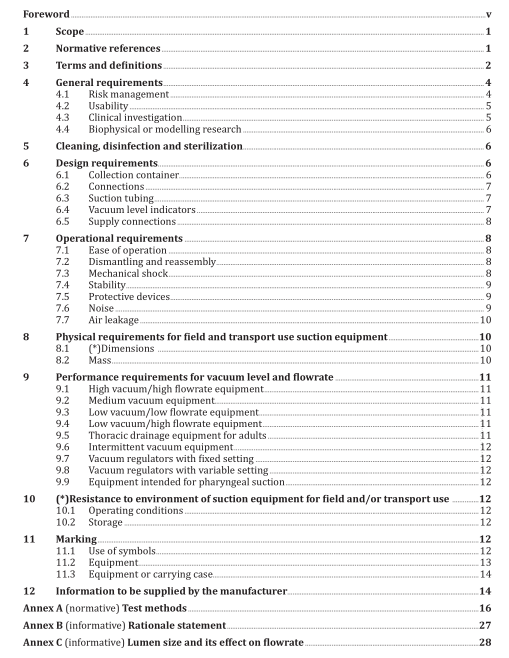

ISO 10079-3:2014 pdf download.Medical suction equipment — Part 3: Suction equipment powered from a vacuum or positive pressure gas source

4.1.2 Suction equipment powered from a vacuum or positive pressure gas source shall, when transported, stored, installed, operated in normal use and maintained according to the instructions of the manufacturer, present no risks that are not reduced to an acceptable level using risk management procedures in accordance with ISO 14971 and which are associated with their intended application, in normal and in single fault condition.

NOTE A situation in which a fault is not detected is considered a normal condition. Fault conditions/hazardous situations might remain undetected over a period of time and, as a consequence, might lead to an unacceptable risk. In that case, a subsequent detected fault condition needs to be considered as a single fault condition. Specific risk control measures need to be determined within the risk management process to deal with such situations.

Check compliance by inspection of the risk management file.

4.1.3 Where requirements of this part of ISO 10079 refer to freedom from unacceptable risk, the

acceptability or unacceptability of this risk shall be determined by the manufacturer in accordance with their policy for determining acceptable risk.

Check compliance by inspection of the risk management file.

4.1.4 The manufacturer may use type tests different from those detailed within this part of ISO 10079,if an equivalent degree of safety is obtained. Alternative test methods shall be validated against the test methods specified in Annex A of this part of ISO 10079.

Check compliance by inspection of the technical file.

4.2 Usability

The manufacturer shall address, in accordance with IEC 60601-1-6 and IEC 62366, the usability

engineering process, and the risk resulting from poor usability.

Check compliance by inspection of the usability engineering file.

4.3 Clinical investigation

Where appropriate, clinical investigation shall be performed under the conditions for which performance is claimed and documented in the risk management file. The clinical investigation shall comply with the requirements of ISO 14155.

NOTE Clinical data may be sourced from:

— clinical investigation(s) of the device concerned, or

— clinical investigation(s) or other studies reported in the scientific literature, of a similar device for which equivalence to the device in question can be demonstrated, or

— published and/or unpublished reports on other clinical experience of either the device in question or a similar device for which equivalence to the device in question can be demonstrated.

Check compliance by inspection of the risk management file.

4.4 Biophysical or modelling research

Where appropriate, validated biophysical or modelling research shall be performed under the conditions for which performance is claimed and documented in the risk management file.

Check compliance by inspection of the technical file.

5 Cleaning, disinfection and sterilization

Parts of the suction equipment which may be subject to contamination shall either be for single use or capable of being cleaned and disinfected or sterilized as appropriate. This includes filters, suction tubing and collection containers.

Parts intended for re-use shall meet the requirements of Clauses 7 and 9, as appropriate, after those components have been submitted to 30 cycles of cleaning and disinfection or sterilization as recommended by the manufacturer.

Check compliance by functional testing.

6 Design requirements

6.1 Collection container

6.1.1 General

The collection container shall clearly show the level of contents in normal use.

Check compliance by inspection.

6.1.2 Container capacity and usable volume

6.1.2.1(*) For suction equipment intended for field use with overfill protection, the usable volume of the collection container shall be not less than 300 ml.

6.1.2.2(*) For suction equipment intended for field use and which is intended to continue operating when the collection container is full, the volume of the collection container shall be not less than 200 ml.

Check compliance by functional testing and inspection.

6.1.2.3 For all other suction equipment, including suction equipment intended for transport use, the usable volume of the collection container shall be not less than 500 ml and the container shall be fitted with overflow protection.

Check compliance by inspection and the tests given in A.2.

6.1.3 Container strength

The collection container shall not implode, crack or permanently deform and shall meet the requirements of Clauses 7 and 9, as appropriate, after being subjected to a pressure of either 120 % of the manufacturer’s recommended maximum vacuum level, or 95 kPa below atmospheric, whichever is less, for 5 min.

Containers intended for re-use shall be tested after 30 cycles of cleaning and disinfection or sterilization as recommended by the manufacturer.

Check compliance by the tests given in A.3.ISO 10079-3 pdf download.iso-10079-3-2014-pdf-download