ISO 9986:2014 pdf download.Composition cork for shoe outsoles

This International Standard specifies requirements for test methods as regards composition cork for the manufacture of outsoles of shoes and boots.

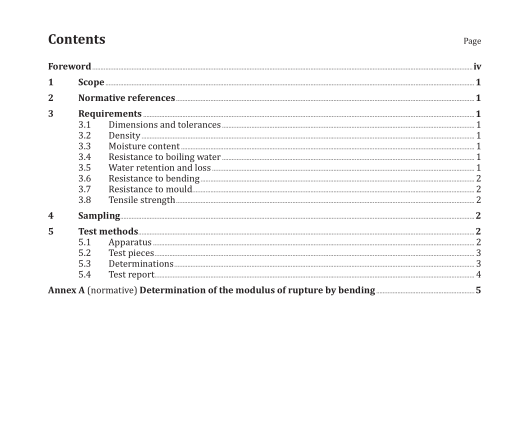

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 4714, Composition cork — Specifications, sampling, packaging and marking

ISO 7322, Composition cork — Test methods

3 Requirements

3.1 Dimensions and tolerances

Unless otherwise agreed, the nominal dimensions of composition cork for the manufacture of outsoles are as follows:

blocks: 1 025 mm × 525 mm × 200 mm

slabs: 1 025 mm × 525 mm × 30 mm

1 025 mm × 525 mm × 60 mm

1 025 mm × 525 mm × 100 mm

The tolerances on these dimensions are specified in ISO 4714.

3.2 Density

Blocks or slabs tested in accordance with 5.3.2 shall have a density not less than 250 kg/m 3 .

3.3 Moisture content

The moisture content of composition cork tested in accordance with 5.3.3 shall not be higher than 8 %.

3.4 Resistance to boiling water

Composition cork tested in accordance with 5.3.4 shall not show signs of disintegration.

3.5 Water retention and loss

Composition cork tested in accordance with 5.3.5 shall not exhibit water retention greater than 30 % and shall show a water loss greater than 40 %.

3.6 Resistance to bending

Blocks or slabs tested in accordance with 5.3.6 shall not exhibit cracks when under a flexion of 10 daN/cm 2 before being immersed in water and of 5 daN/cm 2 after immersion in water.

3.7 Resistance to mould

Composition cork tested in accordance with 5.3.7 shall not exhibit the development of mould.

3.8 Tensile strength

The tensile strength of the composition cork determined in accordance with 5.3.8 shall be at least of 200 kPa (see ISO 4714).

4 Sampling

From each homogeneous lot of up to 500 units, take at random 1 % of the blocks or slabs. From each homogeneous lot of more than 500 units, take 0,2 % of the blocks or slabs up to a maximum of 10 blocks or slabs.

The number of the blocks or slabs to be taken shall be rounded off to the nearest higher unit.

5 Test methods

5.1 Apparatus

See Annex A and ISO 7322.

5.1.1 Vernier gauge, with a resolution of 0,1 mm.

5.1.2 Container, to carry out the test of retention and loss of water.

5.1.3 Electrical disc saw.

5.2 Test pieces

5.2.1 Preparation

Laminate the blocks or slabs to obtain test samples with thickness of 25 mm.

Using a saw, cut each sample at the extremities and in the middle to obtain the dimensions and number of test pieces as indicated in Table 1.

5.2.2 Conditioning

The tests shall be carried out at room temperature, using test pieces previously conditioned for 24 h in a conditioning chamber at a temperature of 23 °C ± 2 °C and a relative humidity of 50 % ± 5 %.

5.3 Determinations

5.3.1 Dimensions

Each of the dimensions of the blocks or slabs, determined by means of a metal ruler, shall be the arithmetic average of three measurements taken on the edges and in the middle of the corresponding face.

Express the results, in millimetres, rounded off to the nearest unit.

5.3.2 Density

Determine the density of the test pieces in accordance with ISO 7322.

5.3.3 Moisture content

Determine the moisture content of the test pieces by drying them in the oven at 103 °C ± 2 °C to constant mass.

5.3.4 Resistance to boiling water

Determine the resistance of the test pieces to boiling water in accordance with ISO 7322.

5.3.5 Water retention and loss

5.3.5.1 Procedure

Determine the mass of a test piece (m 0 ).

Immerse the test piece for three days in a container containing distilled water.

Remove excess water with filter paper and weigh again (m 1 ).

Leave the test piece for 16 h at the ambient temperature and weigh once again (m 2 ).

Repeat these operations for all the test pieces.

Calculate the water retention and water loss based on the arithmetic averages of the results obtained for all test pieces.

Express the results as percentage, rounded off to the nearest integer.ISO 9986 pdf download.ISO 9986 pdf download