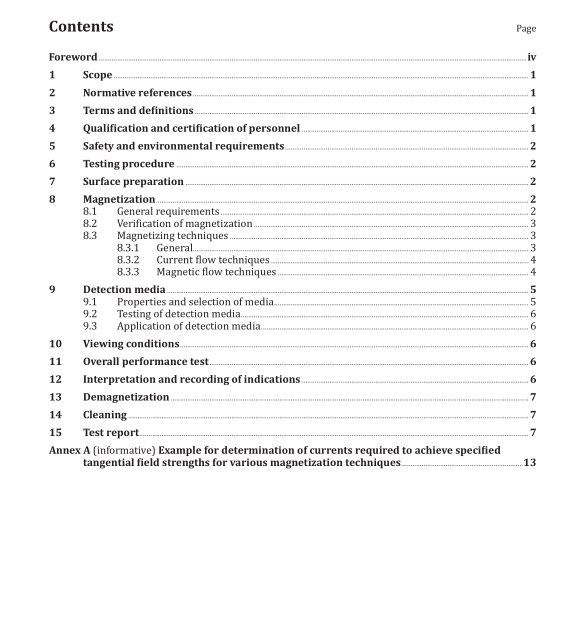

ISO 9934-1:2015 pdf download.Non-destructive testing — Magnetic particle testing — Part 1: General principles

5 Safety and environmental requirements

All international, European, national, and local regulations which include health, safety and environment shall be taken into account. Magnetic particle testing often creates high magnetic fields close to the object under test and the magnetizing equipment. Items sensitive to these fields should be excluded from such areas.

6 Testing procedure

When required at the time of enquiry and order, magnetic particle testing shall be performed in accordance with a written procedure. The procedure can take the form of a brief technique sheet, containing a reference to this and other appropriate standards. The procedure should specify testing parameters in sufficient detail for the test to be repeatable. All testing shall be performed in accordance with an approved written procedure or the relevant product standard shall be referenced 7 Surface preparation Areas to be tested shall be free from dirt, scale, loose rust, weld spatter, grease, oil, and any other foreign materials that can affect the test sensitivity.

The surface quality requirements are dependent upon the size and orientation of the discontinuity to be detected. The surface shall be prepared so that relevant indications can be clearly distinguished from false indications. Non-ferromagnetic coatings up to approximately 50 µm thickness, such as unbroken adherent paint layers, do not normally impair detection sensitivity.

Thicker coatings reduce sensitivity. Under these conditions, the sensitivity shall be verified. There shall be a sufficient visual contrast between the indications and the test surface. For the non- fluorescent technique, it might be necessary to apply a uniform, thin, temporarily adherent layer of approved contrast aid paint.

8 Magnetization

8.1 General requirements

The minimum magnetic flux density (B) regarded as adequate for testing is 1 T. The applied magnetic field (H) required to achieve this in low alloy and low carbon steels is determined by the relative permeability of the material. This varies according to the material, the temperatures, and also with the applied magnetic field and for these reasons it is not possible to provide a definitive requirement for the applied magnetic field. However, typically a tangential field of approximately 2 kA/m will be required.

Where time varying currents (I) are used to produce a magnetic field (which will also be time varying), it is important to control the crest factor (shape) of the waveform and the method of measurement of the current in order to establish a repeatable technique. Both peak and RMS measurements are typically used and measurement of the values can be affected by the response of the instrument.

For this reason, only instruments that respond directly to the waveform shall be used (e.g. True RMS meters with appropriate crest factor capability for accurate RMS measurements). Instruments that calculate peak or RMS values based on theoretical calculation derived from other values shall not be used.

This shall also apply to instruments used to measure magnetic fields Smooth shaped waveforms provide low crest factors and least variation between peak and True RMS values and are regarded as preferable for magnetic particle testing. Waveforms with a crest factor (i.e. l pk /l RMS ) greater than 3 shall not be used without documented evidence of the effectiveness of the technique. When using multidirectional techniques, the current used shall be purely sinusoidal or phase controlled but the phase cutting shall not be more than 90°. Practical demonstration that the technique is effective in all directions shall be carried out (e.g. using sample parts with known defects or shim type indicators). Provided the permeability is in the normal range and the current measurement methods are controlled as described, calculations based on the use of 2 kA/m can provide a valuable method of technique preparation.

The use of either peak current or True RMS current is acceptable if the crest factor is known. Knowing the entire waveform of the magnetizing curve would be optimal, but knowing the crest factor is a good practical approximation. For pure sinusoidal waveforms, the relationship between peak, mean, and RMS is shown in Annex A. Techniques based on calculation shall be verified before implementation. NOTE 1 For steels, with low relative permeability, a higher tangential field strength might be necessary.

If magnetization is too high, spurious background indications can appear, which could mask relevant indications. If cracks or other linear discontinuities are likely to be aligned in a particular direction, the magnetic flux shall be aligned perpendicular to this direction where possible.ISO 9934-1 pdf download.ISO 9934-1 pdf download