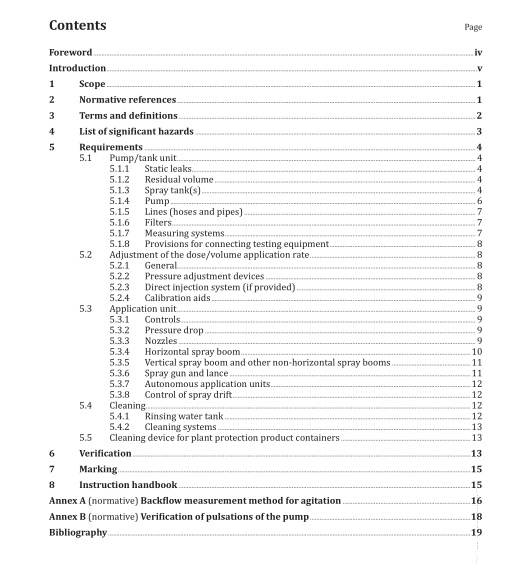

ISO 16119-4:2014 pdf download.Agricultural and forestry machinery — Environmental requirements for sprayers — Part 4: Fixed and semi-mobile sprayers

This part of ISO 16119 specifies requirements and the means for their verification for the design and performance of fixed and semi-mobile sprayers, as defined in 3.1 and 3.2, with regard to minimizing the potential risk of environmental contamination during use, including misuse foreseeable by the manufacturer.

This type of spraying system is generally a combination of separate elements (main tank, pump and application unit) that can be assembled in fixed installations (fixed sprayers) or with moving parts (semi-mobile sprayers).

It does not apply to application equipment for space/spatial treatments.

It is intended to be used with ISO 16119-1, which gives general requirements common to all the sprayer types covered by ISO 16119. When requirements of this part of ISO 16119 are different from those stated in ISO 16119-1, the requirements of this part of ISO 16119 take precedence over the requirements of ISO 16119-1 for machines within the scope of this part of ISO 16119. This part of ISO 16119 does not cover safety aspects (see ISO 4254-6).

This part of ISO 16119 is not applicable to sprayers manufactured before the date of its publication.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

EN 837-1, Pressure gauges – Part 1: Bourdon tube pressure gauges – Dimensions, metrology, requirements and testing

ISO 4102:1984, Equipment for crop protection — Sprayers — Connection threading

ISO 4254-6:2009, Agricultural machinery — Safety — Part 6: Sprayers and liquid fertilizer distributors

ISO 4288:1996, Geometrical Product Specifications (GPS) — Surface texture: Profile method — Rules and procedures for the assessment of surface texture

ISO 5681, Equipment for crop protection — Vocabulary

ISO 5682-1:1996, Equipment for crop protection — Spraying equipment — Part 1: Test methods for sprayer nozzles

ISO 5682-2:1997, Equipment for crop protection — Spraying equipment — Part 2: Test methods for hydraulic sprayers

ISO 5682-3:1996, Equipment for crop protection — Spraying equipment — Part 3: Test method for volume/hectare adjustment systems of agricultural hydraulic pressure sprayers

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 5681 and the following apply.

3.1 fixed sprayer

machine primarily for spraying plant protection products in covered structures, and where the pump/tank unit (3.3) and/or application unit (3.4) do not move

3.2 semi-mobile sprayer

machine primarily for spraying plant protection products on crops grown in covered structures, and where the pump/tank unit (3.3) and application unit (3.4) are separately moveable

3.3 pump/tank unit

device comprising at least the pump and the spray liquid tank

Note 1 to entry: They can be built together as one unit or separate units.

3.4 application unit

device consisting of one or more nozzles/spray generators with or without air-assistance, and used with a separate pump/tank unit to which it is connected by a pipeline

Note 1 to entry: There are sprayers where the application unit moves in the crop rows or over the target independently from the pump/tank unit and others where the application unit is stationary and the target is moved

Note 2 to entry: The application unit can be a spray gun/lance or a horizontal and/or vertical spray boom. The application unit can be equipped with a fan to provide air to transport the spray droplets to the target. The application unit can be moved in the row or over the target (manually or motorized). The spray application controls can be manual or automatic.

4 List of significant hazards

Table 1 specifies the significant hazards, the significant hazardous situations and significant hazardous event(s) covered by this part of ISO 16119 that have been identified by risk assessment as being relevant for this type of machine with regard to environmental contamination, and which require specific action by the designer or manufacturer to eliminate or to reduce environmental contamination. Attention is drawn to the necessity to verify that the environmental requirements specified in both ISO 16119-1 and this part of ISO 16119 apply to each significant hazard presented by a given machine and to validate that the risk assessment is complete.ISO 16119-4 pdf download.ISO 16119-4 pdf download