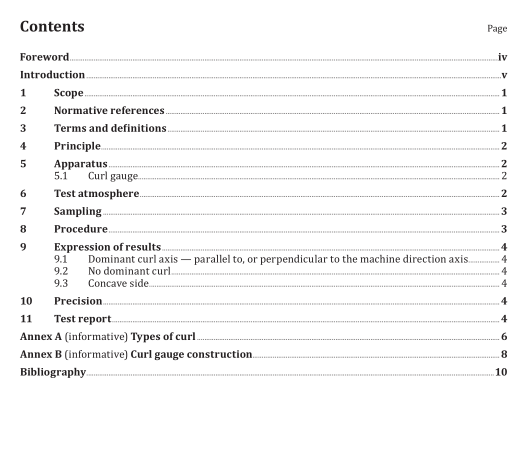

ISO 14968:2022 pdf download.Paper and board — Cut-size office paper — Measurement of curl in a pack of sheets

7 Sampling

7.1 If tests are being made to evaluate a lot, the sample shall be selected in accordance with ISO 186:2002, 5.1.

7.2 For the purposes of this document, a test piece is understood to be a pack of 10 to 15 consecutive sheets.

7.3 When taking paper from unopened packages, open the package, pull out 10 to 15 consecutive sheets and make the measurement, in accordance with the procedure (see Clause 8). To ensure that only samples which have experienced minimum exposure to the atmosphere are selected, do not pull sheets from near the top or bottom of the pack.

7.4 When taking paper from stacks that are not wrapped, pull 10 to 15 sheets from some distance down the stack to avoid paper that has been exposed to the atmosphere. Make the measurement, in accordance with the procedure (see Clause 8) without delay.

7.5 Identify the machine direction and referenced side of the paper. The referenced side is the side that should be imaged first. If the machine direction (MD) is unknown, it may be determined by reference to the Bibliography.

7.6 When sampling paper after copying or from a printing device, allow at least 2 min of continuous operation for a stack to build and then pull out 10 to 15 sheets from the machine and make the measurement in accordance with Clause 8 without delay. Do not pull sheets from the top or bottom of the printed stack.

8 Procedure

8.1 It is recommended that the curl for all four edges be measured, except when there is a very dominant curl with axis parallel or perpendicular to the paper’s machine direction. In this case, only the curl of the two short or two long edges needs to be measured. The procedure that follows applies to all four edges of the test piece. If no dominant curl is apparent, begin at any of the four edges.

8.2 Select the test piece in accordance with 7.3, 7.4 or 7.6.

8.3 Hold the test piece on one edge vertically between the thumb and forefinger at mid-height, about 10 mm from the edge. Immediately superimpose the opposite free edge without contact over the curl gauge arcs and read the radius of curvature for whichever arc is the nearest match to the test piece.

NOTE In the event of a diagonal curl, a more accurate estimate of the curl magnitude can be obtained if the test piece is suspended at such a point on its edge that the curl axis is vertical. Using a set of templates, as suggested in 5.1, will facilitate this measurement.

8.4 For non-processed test pieces, record the side towards which the paper curls, that is, towards or away from the referenced side. For test pieces processed through a copier or other printing device, record whether the test piece curls towards or away from the last imaged side. NOTE For determining curl after copying or processing through a printing device: if there is significant splaying in the pack of sheets, such that no single curl value can be measured, it is probable that the copier or printer has not reached a satisfactory operating temperature. In this case, the test can be rerun after feeding at least 100 copies through the machine before pulling out the test sheets.

8.5 Note and record the dominant direction of the curl axis as parallel to, or perpendicular to the machine direction. Note if there is any evidence for a diagonal curl.

In the case of a significant diagonal curl, the results shall be interpreted with caution.

8.6 Record the presence of any double curl.

9 Expression of results

9.1 Dominant curl axis — parallel to, or perpendicular to the machine direction axis

Calculate the mean of the two measured edges, in reciprocal metres.

9.2 No dominant curl

Report all four measured edges separately, in reciprocal metres.

NOTE In this case, the highest curl value and curl direction can be highlighted.

9.3 Concave side

Report the side to which the paper curls, that is, towards or away from the referenced side.ISO 14968 pdf download.ISO 14968 pdf download