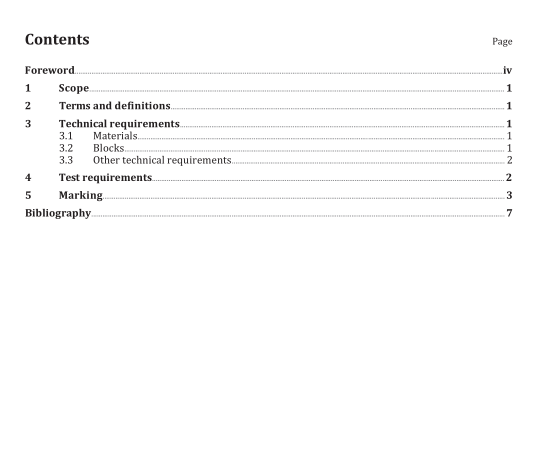

BS ISO 16855:2013 pdf download.Ships and marine technology — Loose gear of lifting appliances on ships — General requirements

3.3 Other technical requirements

3.3.1 “C” type hooks shall be so designed as to prevent the risk of the hook from catching on the ship’s structure or other obstruction when hoisting by means of a hook shelter. Hooks for special purposes, such as for lifting freight containers, shall comply with the appropriate recognized International Standards.

3.3.2 Swivel shall be provided between the hook and short link chain or other item for lifting cargo, and capable of rotating freely and preventing from getting loose.

3.3.3 It is recommended that heavy load such as bob weight or short link chain be attached to the hook, such that disorder of reeling rope will not occur when the winch is working in no load condition.

3.3.4 The shackle pin end shall be screwed and provided with devices to prevent from getting loose. Shackles used for attaching the lifting gear (such as hooks, bob weight, or short link chains for lifting cargo, etc.) shall be provided with countersunk pins.

3.3.5 The thickness of triangle plates connecting short link chains and cargo runners shall be appropriate to the associated shackle so as to minimize the clearance between them

. 3.3.6 The construction of rigging screws shall be capable of preventing their end fittings from turning. The end fittings of the rigging screw shall be forged in one piece. The rigging screws of hook type end fittings shall not be used in the lifting appliance system.

3.3.7 Chains used as span chain or as part of preventer guy shall be of studless long link chains. Preventer guy with patent clip shall be fitted with stop device; the distance between the device and the end clip shall be as short as practical and, in general, not greater than one pitch of the clips.

3.3.8 The items of loose gear, such as eyes, links, shanks, straps and hooks, etc., that have a wastage over 10 % of their original dimensions and a wastage of pins over 6 % of their original dimensions, or cracks or permanent deformation, and any breakage or cracks on the sheaves, shall be replaced or repaired immediately.

3.3.9 Welding shall not be used to lengthen, alter, or repair chains, hooks, links, shackles, or swivels.

4 Test requirements

4.1 Where testing machines are used to apply test loads, they shall be calibrated biennially by a recognized unit and the accuracy shall be within ±2 %. Where test weights are used to apply test loads, the weights shall be certified as accurate to within ±2 %.

4.2 Every item of loose gear shall be proof-tested. The proof load applied to each item of loose gear shall be as the requirements given in Table 2 and associated notes. Proof load shall be applied to each item with a testing machine or test weight for a duration of not less than 5 min.

NOTE 1 The safe working load for single sheave blocks, including single sheave blocks with beckets, shall be taken as one-half of the load on the head fitting.

NOTE 2 The safe working load for a multi-sheave block shall be taken as the load on the head fitting.

NOTE 3 As an alternative to the testing per Table 2, the loose gear can be proof-tested in accordance with the requirements of the Flag Administration or a Classification Society acceptable to the Flag Administration provided the proof test is equal to or greater than the proof test specified in Table 2.

4.3 For blocks, test loads shall be taken as the total load on the head fittings of blocks during tests.

If blocks are provided with beckets, during their proof tests, loads applied to beckets shall be taken as their proof test loads for acceptance.

4.4 In any case when single sheave blocks are used, shackles or end fittings connected to blocks should be stamped with twice the safe working load marked on the blocks.

4.5 After proof testing, each item of loose gear shall be thoroughly examined for deformation, cracks,or other defects and to ensure that its rotating parts can rotate freely.

4.6 Short and long link chains shall be subjected to a breaking test in addition to the proof test as required in Table 2. In general, a sample of 5 links length shall be taken from each length of chain measuring 55 m and shall withstand a breaking load not less than 4 × SWL for the chain.

4.7 Where the design of a lifting beam or similar item is such that the load can be lifted and supported in more than one manner, each arrangement shall be separately tested.

4.8 Under the following circumstances, loose gear shall be re-tested:

a) in case of no corresponding certificates of examination to prove that components have been tested in advance;

b) after any repair or change that might affect component strength.

5 Marking

5.1 Every item of loose gear which has been proof-tested and examined and found satisfactory in accordance with the above Clause 5 shall be marked visibly and permanently.BS ISO 16855 pdf download.BS ISO 16855-2013 pdf download