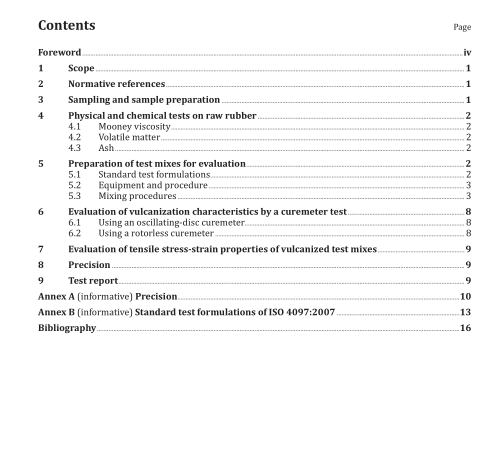

ISO 4097:2014 pdf download.Rubber, ethylene-propylene-diene (EPDM) — Evaluation procedure

This International Standard specifies the following:

— physical and chemical tests on raw rubbers;

— standard materials, standard test formulations, equipment, and processing methods for evaluating the vulcanization characteristics of ethylene-propylene-thene rubbers (E PDM). including oil- extended types-

2 Normative references

The following documents, in whole or in part, are normatively referenced in thts document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the btest edition of the referenced document (including any amendments) applies.

ISO 37, Rubber, vulcanized or thermoplastic — Determination oftensile stress-strain properties ISO 247, Rubber — Determination of ash

ISO 248-1. Rubber, raw — DetermlnaUon of volatile-matter content — Part 1: Hot-mIll method and oven method

ISO 248-2. Rubber, raw — Determination of volatile-matter content — Port 2: The rinogrovimerric methods using an automatic analyser with on infrared drying umt

ISO 289-1, Rubber, unvulcanised — Determinations usingasheoring-disc viscometer— Port 1: Determination of Mooney viscosity

ISO 1795. Rubber, row natural and row synthetic — Sampling and further preparative procedures

ISO 2393, Rubber test mixes — Preparation, mixing and vulcanizot ion — Equipment and procedures

ISO 3417, Rubber — Measurement of vulcanizat ion characteristics with the oscillating disc curemeter

ISO 6502, Rubber — Guide to the use of caremeters

ISO 23529, Rubber — General pro cedures for preparing and conditioning test piecesfor physical test methods

3 Sampling and sample preparation

3.1 Take a laboratory sample of approximately 1,5 kg Ir the method described in ISO 1795.

3.2 Prepare the test portion in accordance with ISO 1795.

4 Physical and chemical tests on raw rubber

4.1 Mooney viscosity

Determine the Mooney viscosity in accordance with ISO 289-1. on a lest portion prepared as indicated in 12 (without massingj

II massing is necessary, maintain the mill roll surFace temperature at 50 € s 5 C (br rubbers with a low Mooney viscosity, a temperature ol 35°C ± S °C ran he used). Massing. If used, shall he mentioned in Lhe test report.

Record the result as ML41i-4) at 125°C unless another test temperature (100°c or 150°C) and/or test time (1.8) mm has been agreed by the interested parties.

4.2 Volatile matter

l)eterrni,w the volatilr matter content In accordance with ISO 248-I or 154) 2414-2.

4.3 Ash

Determine the ash content in accordance with method A or method B of ISO 247.

5 Preparation of test mixes for evaluation

5.1 Standard test formulations

The standard test formulations are given in Tabft.L in which;

a) formulation 1 is applicable to nonoilextended EPDMs with a nominal ethylene content not higher than 67% by niass

b) forniulat ion 2 is applicahle to non-oll-eslended KPDMs with a nominal ethylene content equal to or higher than 67% by mass;

c) formulation 3 is applicable to non-oil-extended low Mooney viscosity EPUMs;

d) formulation 4 is applicable to oil-extended EPDMs containing SO or less parts by mass of oil per 100 parts of rubber:

e) formulation S is applicable to oil-extended EPDMs containing more than 50 but less than 80 parts by mass ol oil per 100 parts of rubber

fl formulation 6 Is applicable to oIl-extended EPI)Ms containing HO or more parts by mass oI oil per 100 parts of rubber.

The materials used shall be national or International Standard reference materials unless no standard reference matenal is available in which case the matenals to be used shall be agreed between the interested parties.

5.2 Equipment and procedure

Equipment and procedure for the preparation, mixing, and vulcanization shall be in accordance with

ISO 2393.

5.3 Mixing procedures

5.3.1 General

Four alternative mixing procedures are specified.

— Method A1: single stage mixing with LIM (laboratory internal mixer) which is the preferred method.

— Method A2: two-stage mixing with LIM.

— Method A3: two-stage mixing using a LIM for initial mixing and mill mixing for final mixing.

— Method B: mill mixing.

Mixing of ethylene-propylene-diene rubbers in the standard test formulations using a mill is more difficult than for other rubbers and the use of a LIM allows better results. Because of the difficulty of mill mixing EPDM rubbers, it is recommended that method B be used only if a LIM is not available.ISO 4097 pdf download.ISO 4097-2014 pdf download