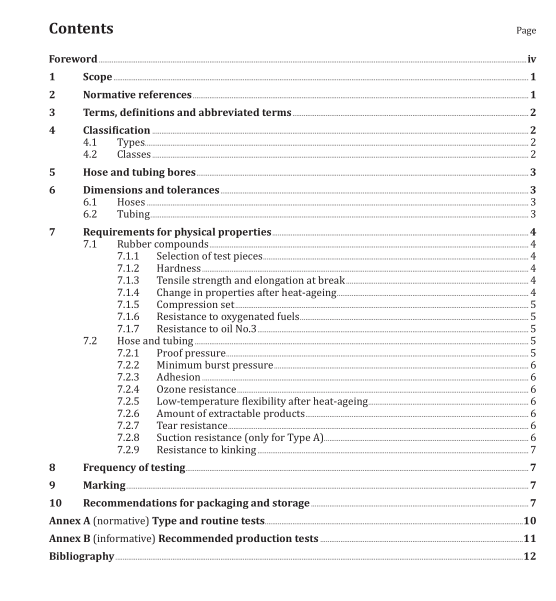

BS ISO 11424:2017 pdf download.Rubber hoses and tubing for air and vacuum systems for internal-combustion engines — Specification

This document specifies requirements for rubber hoses and tubing for use in the various air and vacuum systems found on internal combustion engines. This document does not cover hoses used for direct power-brake actuation in trucks and trailers, nor for air intakes and ducting within the passenger compartment. The highest-temperature hoses are generally used for turbocharger applications. All hoses and tubing remain serviceable down to −40°C.

NOTE Although the term vacuum is generally used, in reality the application is one of reduced air pressure used for the purposes of actuation or monitoring of the various engine-system components. The air carried by the tubing or hoses may be clean and free of contaminants but may also contain oil, fuel and their vapours as contamination, due to the particular installation and application.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 37:2011, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties

ISO 48, Rubber, vulcanized or thermoplastic — Determination of hardness (hardness between 10 IRHD and 100 IRHD)

ISO 188, Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests

ISO 815-1:2014, Rubber, vulcanized or thermoplastic — Determination of compression set — Part 1: At ambient or elevated temperatures

ISO 1402, Rubber and plastics hoses and hose assemblies — Hydrostatic testing

ISO 1629, Rubber and latices — Nomenclature

ISO 1817:2015, Rubber, vulcanized or thermoplastic — Determination of the effect of liquids

ISO 3302-1, Rubber — Tolerances for products — Part 1: Dimensional tolerances

ISO 4671, Rubber and plastics hoses and hose assemblies — Methods of measurement of the dimensions of hoses and the lengths of hose assemblies

ISO 7233:2016, Rubber and plastics hoses and hose assemblies — Determination of resistance to vacuum

ISO 7326, Rubber and plastics hoses — Assessment of ozone resistance under static conditions

ISO 8033, Rubber and plastics hoses — Determination of adhesion between components

ISO 8330, Rubber and plastics hoses and hose assemblies — Vocabulary

ISO 10619-1:2011, Rubber and plastics hoses and tubing — Measurement of flexibility and stiffness —Part 1: Bending tests at ambient temperature

ISO 10619-2:2011, Rubber and plastics hoses and tubing — Measurement of flexibility and stiffness —Part 2: Bending tests at sub-ambient temperatures

3 Terms, definitions and abbreviated terms

For the purposes of this document, the terms and definitions given in ISO 8330 and the abbreviated terms given in ISO 1629 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http:// www .electropedia .org/

— ISO Online browsing platform: available at http:// www .iso .org/ obp

4 Classification

4.1 Types

Type A — internally reinforced hose with a working pressure up to 0,3 MPa (3 bar).

Type B — homogeneous tube with a working pressure up to 0,12 MPa (1,2 bar).

4.2 Classes

Class 1 — Long-term working temperature up to 70 °C; maximum working temperature up to 100 °C.Not recommended for applications where resistance to oils, fuel and their vapours is required.

NOTE 1 Typically, styrene-butadiene rubber (SBR) can be used.

Class 2 — Long-term working temperature up to 100 °C; maximum working temperature up to 125 °C.Resistant to oils and their vapours.

NOTE 2 Typically, chloroprene rubber (CR) can be used.

Class 3 — Long-term working temperature up to 100 °C, maximum working temperature up to 125 °C.Resistant to oils, fuels and their vapours.

NOTE 3 Typically, acrylonitrile-butadiene rubber (NBR) can be used.

Class 4 — Long-term working temperature up to 125 °C, maximum working temperature up to 150 °C.Not recommended for applications where resistance to oils, fuels and their vapours is required.

NOTE 4 Typically, ethylene-propylene rubber (EPM or EPDM) can be used.

Class 5 — Long-term working temperature up to 125 °C, maximum working temperature up to 150 °C.Resistant to oils and their vapours.

NOTE 5 Typically, chlorinated or chlorosulfonated polyethylene (CM or CSM) can be used.

Class 6 — Long-term working temperature up to 125 °C, maximum working temperature up to 150 °C.Resistant to oils, fuels and their vapours.

NOTE 6 Typically, epichlorohydrin or hydrogenated nitrile rubbers (CO, ECO or HNBR) can be used.

Class 7 — Long-term working temperature up to 150 °C, maximum working temperature up to 175 °C.Not recommended for applications where resistance to oils, fuels and their vapours is required.

NOTE 7 Typically, silicone rubber (VMQ) can be used.BS ISO 11424 pdf download.BS ISO 11424-2017 pdf free download