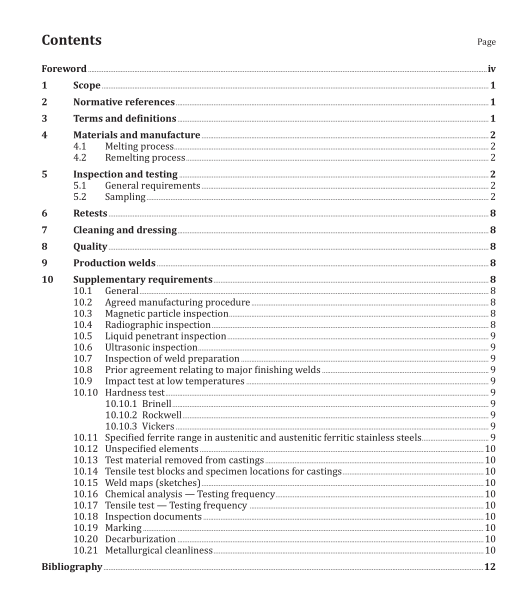

BS ISO 16468:2015 pdf download.Investment castings (steel, nickel alloys and cobalt alloys) — General technical requirements

4 Materials and manufacture

4.1 Melting process

Primary heats shall be made by the electric furnace process, with or without separate refining, such as argon-oxygen-decarburization (AOD), vacuum-oxygen-decarburization (VOD), vacuum-induction- melting (VIM), etc., unless otherwise specified in the individual specification or agreed upon between the purchaser and manufacturer. Primary heats may be used directly for producing castings or converted into ingot, bar, shot, or other suitable form, for later remelting as a sub-heat.

4.2 Remelting process

Sub-heats shall be produced from primary-heat metal in suitable batch sizes by an electric induction furnace, with or without atmosphere protection, such as vacuum or inert gas, unless otherwise specified in the individual specification or agreed upon between the purchaser and manufacturer. Revert (gates, sprues, risers, and rejected castings) shall not be remelted except in primary heats. Additions of up to 5 %, by mass, are permitted for compositional adjustments and deoxidation.

5 Inspection and testing

5.1 General requirements

The general requirements for inspection and testing shall be in accordance with ISO 4990, except as described in 5.2.

5.2 Sampling

5.2.1 If castings are poured directly from one or more primary heats, then the samples for chemical and other required testing shall also be poured directly from each of the primary heats. 5.2.2 Unless otherwise specified by the purchaser, test blocks may be taken from castings, may be cast integrally with the castings, or may be cast in separate moulds of the same type and materials as those used for the castings. Samples for the determination of the chemical composition may be cast in other types of mould.

5.2.3 If castings are poured from a sub-heat, then the samples for chemical and other required tests shall also be poured from a sub-heat of the same primary melt, but not necessarily from the same sub- melt as the castings. The sub-melt used for the test samples shall be produced using the same practices and additions as used for the castings.

5.2.4 Examples of test blocks which may be used for mechanical testing are shown in Figure 1, except when 10.14 is specified. The test block in Figure 1 d) may be employed only for austenitic alloy castings with a ruling thickness less than 65 mm.

6 Retests

In addition to the requirements of ISO 4990, if any specimen shows defective machining or develops flaws, it may be discarded and another specimen substituted from the same primary heat.

7 Cleaning and dressing

All the castings shall be cleaned and dressed sufficiently to determine compliance with the requirements of Clause

8. Additional dressing may be agreed at the time of the enquiry and order. If the pattern is supplied by the purchaser, or is produced using a die supplied by the purchaser, the dimensions of the casting shall be as produced by the pattern or die.

8 Quality

8.1 Visual standards for acceptance shall be agreed between the purchaser and manufacturer. ISO 11971 may be used to specify visual surface standards. Other surface conditions shall meet the visual acceptance standards specified in the order. Unacceptable visual surface discontinuities shall be removed and their removal verified by visual examination.

8.2 When additional inspection is desired, 10.3, 10.4, 10.5, 10.6, or 10.7 may be specified. 9 Production welds Production welding shall be in accordance with the requirements of ISO 11970. 10 Supplementary requirements 10.1 General One or more of the following supplementary requirements may be applied when specified in the enquiry and order. Additional supplementary requirements may also be found in ISO 4990. Details of these supplementary requirements shall be agreed upon by the manufacturer and purchaser at the time of the enquiry and order. The specified tests shall be carried out before delivery of the castings.

10.2 Agreed manufacturing procedure

At the time of enquiry and order, the purchaser may require prior approval of the manufacturing process.BS ISO 16468 pdf download.BS ISO 16468 pdf download