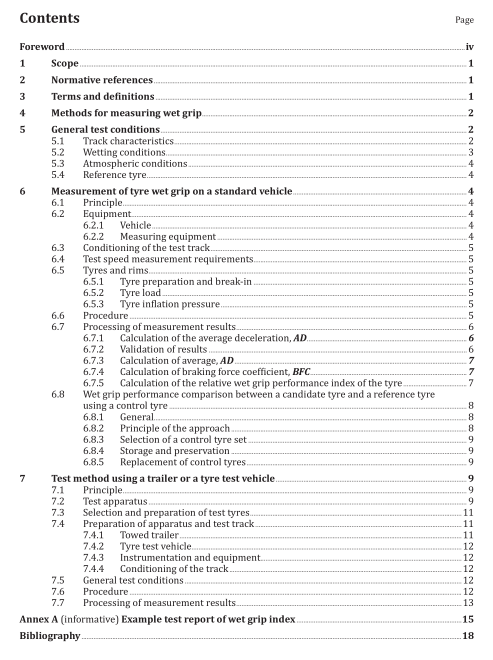

BS ISO 23671:2015 pdf free download.Passenger car tyres — Method for measuring relative wet grip performance — Loaded new tyres

5.3 Atmospheric conditions

The wind conditions shall not interfere with wetting of the surface (wind-shields are allowed).

Both the wetted surface and the ambient temperature shall be between

— 2 °C and 20 °C for the snow tyres, and

— 5°C and 35 °C for the normal tyres.

Moreover, the wetted surface temperature shall not vary during the test by more than 10 °C.

The ambient temperature must remain close to the wetted surface temperature; the difference between the ambient and the wetted surface temperature must be less than 10 °C.

5.4 Reference tyre

The specifications of the SRTT, tyre size P225/60R16, are defined in ASTM F2493-08.

6 Measurement of tyre wet grip on a standard vehicle

6.1 Principle

The test method covers a procedure for measuring the deceleration performance of passenger car tyres during braking, using an instrumented passenger car having an Antilock Braking System (ABS).

Starting with a defined initial speed, the brakes are applied hard enough on four wheels at the same time to activate the ABS. The average deceleration is calculated between two defined speeds, with an initial speed of 80 km/h and a final speed of 20 km/h.

6.2 Equipment

6.2.1 Vehicle

Permitted modifications using a standard-model passenger car equipped with an ABS are as follows:

— those allowing the number of tyre sizes that can be mounted on the vehicle to be increased;

— those permitting automatic activation of the braking device to be installed.

Any other modification of the braking system is prohibited.

6.2.2 Measuring equipment

The exposed portions of the system shall tolerate 100 % relative humidity (rain or spray) and all other conditions, such as dust, shock and vibrations, which can be encountered in regular operation.

The vehicle shall be fitted with a sensor suitable for measuring speed on a wet surface and distance covered between two speeds.

To measure vehicle speed, a fifth wheel or non-contact precision (including radar, GPS, etc.) speedmeasuring system shall be used.

The following tolerances shall be respected:

— for speed measurement: ±1 % or ±0,5 km/h, whichever is greater;

— for distance: ±1 × 10 −1 m.

The measured speed or the difference between the measured speed and the reference speed for the test should be displayed inside the vehicle, so that the driver can adjust the speed of the vehicle.

A data acquisition system can be used for storing the measurements.

6.3 Conditioning of the test track

Condition the pavement by conducting at least 10 test runs with tyres not involved in the test programme at 90 km/h (which is higher than the initial test speed to guarantee that a sufficient length of track is conditioned).

6.4 Test speed measurement requirements

The speed at the start of braking shall be (85 ± 2) km/h.

The average deceleration shall be calculated between 80 km/h and 20 km/h.

6.5 Tyres and rims

6.5.1 Tyre preparation and break-in

Trim the test tyres to remove all protuberances on the tread surface caused by mould air vents or flashes at mould junctions.

Fit the test tyres on rims in accordance with ISO 4000-1 using conventional mounting methods. Ensure proper bead seating by the use of a suitable lubricant. Excessive use of lubricant should be avoided to prevent slipping of the tyre on the wheel rim.

Place the fitted test tyres in a location such that they all have the same ambient temperature prior to testing, and shield them from the sun to avoid excessive heating by solar radiation.

For tyre break-in, perform 10 braking runs.

6.5.2 Tyre load

The static load on each front axle tyre shall lie between 60 % and 90 % of the tested tyre load capacity.

Tyre loads on the same axle should not differ by more than 10 %.

6.5.3? Tyre? inflation? pressure

On the front and rear axles, the inflation pressures shall be 220 kPa (for standard load and extra load versions).

Check the tyre pressure just prior to testing at ambient temperature and adjust if required.BS ISO 23671 pdf download.BS ISO 23671 pdf download