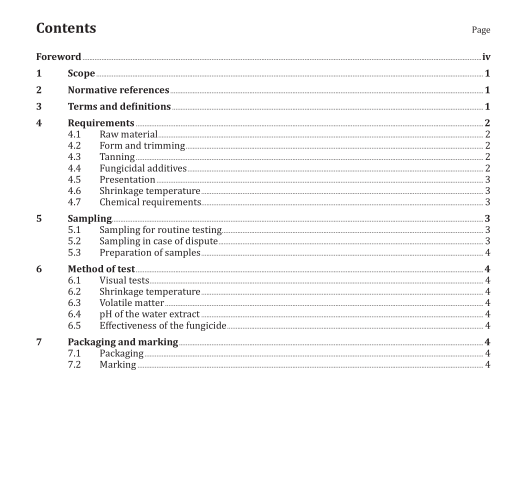

BS ISO 5433:2013 pdf download.Leather — Bovine wet blue — Specification

This International Standard specifies requirements, methods of sampling and methods of test for wet blue leather produced from bovine hides and parts of bovine hides tanned without hair and with the use of basic chromium sulfate as the primary tanning agent.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 2418, Leather — Chemical, physical and mechanical and fastness tests — Sampling location

ISO 3380, Leather — Physical and mechanical tests — Determination of shrinkage temperature up to 100 °C

ISO 4045, Leather — Chemical tests — Determination of pH

ISO 4684, Leather — Chemical tests — Determination of volatile matter

ISO 5398-1, Leather — Chemical determination of chromic oxide content — Part 1: Quantification by titration ASTM D4576, Standard test method for mold growth resistance of wet blue

3? Terms? and? definitions

For the purposes of this document, the following terms and definitions apply.

3.1 cured

preserved temporarily from putrefaction until it can be tanned

Note 1 to entry: Any method of curing, including wet or dry salting or drying, is included.

3.2 pigmentation

colouration produced by fungi growing on wet blue chrome leather

Note 1 to entry: The colouration produced by fungi will normally be black, white, green or yellow but can also be pink or violet.

3.3 belly

the part of the hide covering the underside and part of the legs of the animal

3.4 dosset

double back part of the hide remaining after the belly has been removed

3.5 shoulder

fore part of the hide covering the shoulders and the neck of the animal, with or without the head

3.6 butt

the part of the hide remaining after the belly and the shoulder have been removed

3.7 side

half a whole hide with offal (head, shoulder and belly) attached, obtained by dividing it along the line of the backbone

3.8 culatta

rear part of the bovine hide, comprising the butt, the belly middles and the hind shanks

3.9 front

fore part of the bovine hide, consisting of the shoulders and fore shanks

4 Requirements

4.1 Raw material

Bovine wet blue hides shall be processed from cured or fresh hides or part hides.

4.2 Form and trimming

4.2.1 Bovine wet blue hide shall be in one or more of the following forms, as specified by the purchaser:

a) whole hides;

b) bellies;

c) dossets (double backs);

d) shoulders;

e) butts;

f) sides;

g) culattas;

h) fronts.

4.2.2 The trim shall be as agreed between the supplier and purchaser

4.3 Tanning

After pretanning operations, bovine hides or part hides shall be tanned with basic chromium sulfate as the primary tanning agent. The cut cross-section shall be such that the hide is completely penetrated by the bluish colour of the chromium sulfate when examined visually. Tanning shall be carried out at a pH of 3,0 or above.

4.4 Fungicidal additives

Fungicides shall be used to inhibit mould growths in bovine wet blue leather.

NOTE 1 Fungicides used to inhibit mould growth and pigmentation should be effective and should not cause a health hazard. The types of fungicide used and their dosage should preferably be agreed between the purchaser and the supplier

NOTE 2 Fungicides should preferably be applied in quantities appropriate to ensure storage for up to 4 months at the temperature and humidity prevailing during storage or transportation.

4.5 Presentation

Bovine wet blue leather shall be well fleshed, and the grain side shall be free from hair, including short hair and fine hair. The size and grading shall be as agreed between the interested parties.

NOTE The wet blue leather should preferably have a tight grain and be free from creases, drum folds and stains caused by iron salts. At least 95 % of the number of pieces in a lot should be free from stains caused by chromium salts, and the aggregate of the stained area in any one piece should not exceed 10 % of the total area of the piece.

4.6 Shrinkage temperature

The shrinkage temperature shall meet the requirement for either low chrome tannage or full chrome tannage given in Table 1, when determined using the method given in ISO 3380.BS ISO 5433 pdf download.BS ISO 5433 pdf download