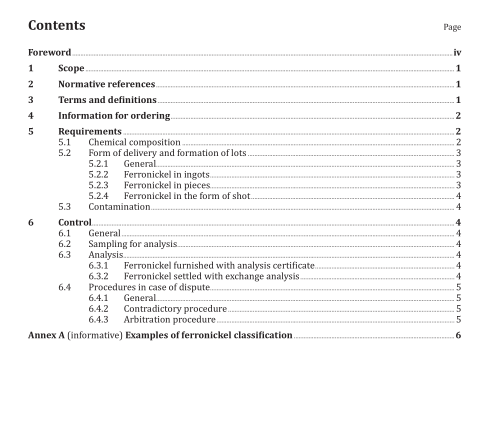

EN ISO 6501:2020 pdf download.Ferronickel – Specification and delivery requirements (ISO 6501:2020)

5.1.4 The designation of ferronickel product is given with the combination of the elements of Tables 1 and 2.

EXAMPLE FE Ni 30 HC MP MS HSi, where L = low, M = medium and H = high.

Other examples of a combination of Tables 1 and 2 are given in Annex A.

5.1.5 The chemical compositions given in Tables 1 and 2 are subject to the precision of the methods of sampling and analysis for ferronickel.

5.2 Form of delivery and formation of lots

5.2.1 General

Ferronickel may be delivered as agreed between the supplier and the purchaser in various forms,e.g. ingots, pieces or shot. The delivered lots, except by special agreement, shall have a minimum tonnage of 5 t.

5.2.2 Ferronickel in ingots

Ingots may be supplied notched or unnotched. Their maximum mass is 100 kg. Their thickness may be within a range of 30 to 150 mm. Their length shall not exceed 1 100 mm.

Lots may be formed in two different ways:

— from material stocked individually from each tapping operation;

— by blending several heats; in this case, except by special agreement, heats shall be selected in a nickel content range from K to (K + 1) %, K being a whole number.

5.2.3 Ferronickel in pieces

Pieces are either cast or cut from ingots. A lot is formed from only one of these two categories of pieces.

The maximum dimension is between 25 and 100 mm. Within a lot, the sizes of pieces shall be uniform.

Lots may be formed in two different ways:

— from material stocked individually from each tapping operation;

— by blending several heats; in this case, except by special agreement, heats shall be selected in a nickel content range from K to (K + 1) %, K being a whole number

5.2.4 Ferronickel in the form of shot

The size of the shot obtained by shotting of liquid material should be within a range of 2 mm to 50 mm.

The ferronickel shot shall be delivered after drying.

Lots generally delivered in bulk may be formed in three different ways:

— from material stocked individually from each tapping operation;

— by reclaiming from blended storage; in this case, the K to (K + n) % range of the nickel content of the blended material may be selected with values of n up to 5;

— by reclaiming from unblended storage; in this case, n shall not exceed 1.

5.3 Contamination

The material shall be as free as possible from surface contaminants such as slag, sand, etc.

6 Control

6.1 General

Sampling and analysis procedures shall be carried out in accordance with relevant International Standards, in particular ISO 8049 for the sampling of ferronickel shot, ISO 8050 for the sampling of ferronickel ingot or pieces, ISO 14284 for the sampling and preparation of samples for analysis of steel and iron applicable for ferronickel in molten stage, and ISO 6352 for the determination of nickel content. Other procedures giving the same accuracy may be agreed upon between the supplier and the purchaser, and the arbitrator in the case of an arbitration procedure.

6.2 Sampling for analysis

6.2.1 During sampling procedures, representatives of both parties may be present, wherever sampling is carried out.

6.2.2 In case of dispute, one of the procedures described in 6.4 may be adopted.

6.3 Analysis

6.3.1 Ferronickel furnished with analysis certificate

The certificate, established by the supplier, gives the nickel content as specified in Table 1 and, if agreed, the content of other elements specified either in Table 2 or additionally agreed.

In case of dispute, the two parties may use the procedures described in 6.4 either for analysis only or for sampling and analysis.

6.3.2 Ferronickel settled with exchange analysis

When an exchange of analysis is decided on by the two parties, the values resulting from analysis of the samples obtained under 6.2.1 for nickel content, and possibly for the content of other elements, shall be exchanged.

If the differences between the results of the analyses of the two parties do not exceed the agreed splitting limits, the mean value shall be accepted.

If the differences exceed splitting limits, the two parties may use the procedures described in 6.4 either for analysis only or for sampling and analysis.EN ISO 6501 pdf download.EN ISO 6501 pdf download