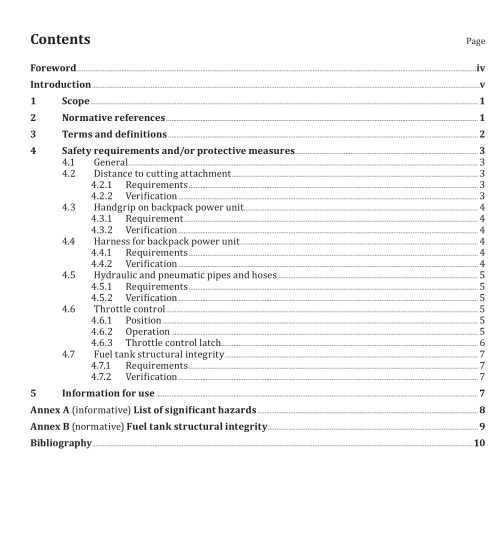

ISO 11806-2:2022 pdf download.Agricultural and forestry machinery — Safety requirements and testing for portable, hand-held, powered brush-cutters and grass- trimmers — Part 2: Machines for use with backpack power unit

4.3 Handgrip on backpack power unit

4.3.1 Requirement

A handgrip shall be available which may be a part of the frame and which shall allow an operator to grasp the backpack power unit for handling and transport.

The handgrip shall be designed such that

— it can be fully gripped by an operator when wearing gloves,

— it provides the necessary sureness of grip by its shaping and surface, and

— its length is at least 100 mm and where, for a bail or closed handgrip, this length is straight or curved at a radius greater than 100 mm together with any blend radius, but not more than 10 mm at one or both ends of the gripping surface.

4.3.2? Verification

The handgrip design shall be verified by inspection, measurement and functional testing.

4.4 Harness for backpack power unit

4.4.1 Requirements

All machines shall be equipped with a double shoulder harness. The harness shall be adjustable to the size of the operator and shall be:

— designed in a way for easy removal; or

— equipped with a quick-release mechanism that ensures that the machine can be removed or released quickly from the operator.

A double shoulder harness is considered to be designed in a way for easy removal, if the left and right shoulder straps are not connected to each other in front of the operator’s body.

If a waist belt and/or supplementary straps to connect the left and right shoulder straps are provided,the double shoulder harness is also considered to be designed in a way for easy removal if they can be released under the load of the machine by using one hand, and there are no more than two release points.

NOTE An example of a release point is a buckle that requires squeezing between a thumb and finger before releasing, such as side release buckles.

A quick release mechanism, if provided, shall be positioned either at the connection between the machine and the harness or between the harness and the operator. The quick release mechanism shall only function by deliberate action of the operator.

It shall be possible to open the quick release mechanism while under load using only one hand and it shall have no more than two release points.

4.4.2? Verification

The harness, its functionality and its adjustment shall be verified by inspection. The quick-release mechanism shall be verified by a functional test, carried out by a person wearing the harness with a vertical load of three times the dry weight of the backpack power unit acting on the suspension point 4.5 Hydraulic and pneumatic pipes and hoses

4.5.1 Requirements

Hydraulic systems shall be in accordance with the safety requirements of ISO 4413:2010. Pneumatic systems shall be in accordance with the safety requirements of ISO 4414:2010.

Hydraulic and pneumatic pipes and hoses subject to internal pressures in excess of 500 kPa shall be shielded so that in the event of rupture during operation of the machine, the fluid cannot be discharged directly onto the operator.

4.5.2? Verification

The shielding of pipes and hoses shall be verified by inspection.

4.6 Throttle control

4.6.1 Position

4.6.1.1 Requirements

The throttle trigger shall be positioned so that it can be pressed and released with a gloved hand while holding the handle to which the throttle trigger is mounted.

4.6.1.2? Verification

The position shall be verified by inspection and functional testing.

4.6.2 Operation

4.6.2.1 Requirements

The machine shall be provided with a throttle trigger that, when released, automatically reverts to the idling position. The throttle trigger, except for grass-trimmers with a cutting attachment where each filament or pivoting non-metallic blade has a kinetic energy of less than 10 J, shall be retained in the idling position by the automatic engagement of a throttle trigger lock-out.

NOTE When fitted to assist starting, a throttle control latch maintains an engine speed higher than the idling speed until the throttle trigger is activated and released.

For brush-cutters and grass-trimmers with a cutting attachment where each filament or pivoting nonmetallic blade has a kinetic energy of 10 J or more, after the starting procedure has been finished,activation of the throttle trigger to increase the engine speed to a point where the cutting attachment starts to move shall only be possible after the throttle trigger lock-out has been disengaged.

The starting procedure is finished when the operator disengages the throttle control latch and the engine returns to idling speed.

For the calculation of kinetic energy, see 4.6.2.2.

When a force is applied to the throttle trigger, while the throttle trigger lockout is engaged, engine speed shall not increase to a point where the clutch engages and cutting attachment movement begins,see 4.6.2.3.ISO 11806-2 pdf download.ISO 11806-2 pdf download