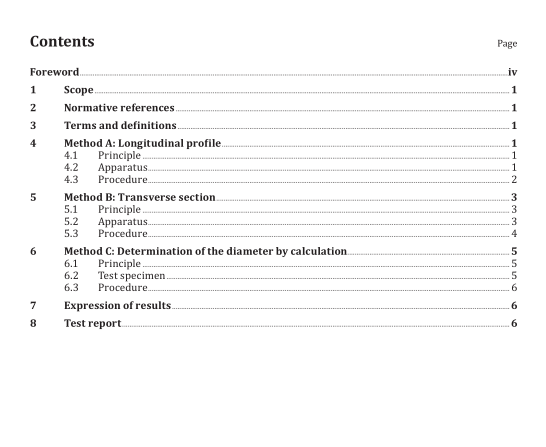

ISO 1888:2022 pdf download.Textile glass — Staple fibres or filaments — Determination of average diameter

This document specifies three test methods used for determining the average diameter (i.e. the average value of actual diameters) of staple fibres or filaments in a textile glass product.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 472, Plastics — Vocabulary

ISO 1889, Reinforcement yarns — Determination of linear density

ISO 12154, Determination of density by volumetric displacement — Skeleton density by gas pycnometry 3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 472 apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

4 Method A: Longitudinal profile

4.1 Principle

Fibres or filaments placed in a liquid medium having a refractive index differing from that of the textile glass are viewed in profile under a microscope and the diameter measured.

4.2 Apparatus

4.2.1 Microscope, equipped with the following:

— An eye-piece with a built-in micrometer graticule, the eye-piece and objective together giving an overall magnification of at least ×400 and preferably ×1 000. The resolution of the microscope shall permit measurement to the nearest 0,5 µm or better.

— A system permitting lateral and rotational movement of the microscope stage.

— An illumination system.

This system may be replaced by or used in conjunction with a microprojector on which specimens can be measured using a transparent scale (preferably a curved scale).

The recommended type of microscope is one using plane-polarized light, and an illumination system with a Kohler light source and an Abbe condenser. A green filter may also be used to give better reading accuracy.

4.2.2 Micrometer scale, with 0,01 mm divisions, for calibration of the optical system.

4.2.3 Glass slide (thickness: 1,10 mm to 1,35 mm), and cover glass (thickness: 0,16 mm to 0,19 mm).

The thickness of the cover glass shall be verified periodically.

4.2.4 Mounting fluid, with a refractive index different (but not too different) from that of the glass under examination. Benzyl alcohol, methyl salicylate, a mixture of one part glycerol and two parts water are adequate media.

4.2.5 Razor blade or scissors.

4.2.6 Muffle furnace, capable of maintaining a temperature of 625 °C ± 25 °C.

4.3 Procedure

4.3.1 It is not always necessary to remove the size from the yarns under examination. Nevertheless,yarns in which the fibres or filaments do not separate from each other in the mounting fluid shall have the size removed by burning off to bare glass at 625 °C in a muffle furnace (4.2.6).

4.3.2 Set up the microscope (4.2.1) with the appropriate optical system and the moving stage.

Calibrate the optical system using the micrometer scale (4.2.2).

4.3.3 Prepare the specimen and the specimen holder as follows:

— Using a sharp cutting device (4.2.5), prepare a specimen of fibres or filaments not exceeding 25 mm in length.

— Place the specimen on the glass slide (4.2.3).

— Separate the fibres or filaments so that they are no longer in a compact bundle, but still essentially parallel to each other.

— Using a glass rod, place one drop of mounting fluid (4.2.4) on the slide so that it wets the specimen 4.3.4 Place the slide on the microscope stage and, after adjusting the position of the specimen to obtain a clear, sharp view of the edges of the fibres or filaments, position the slide so that the micrometer graticule in the eyepiece is perpendicular to one of the fibres or filaments.

4.3.5 Move the micrometer graticule from one edge of the fibre or filament to the other edge and note the distance moved.

When using a microprojector (see 4.2.1), simply measure the distance from edge to edge of the fibre or filament on the transparent scale.

4.3.6 Move the slide around to obtain 25 readings on randomly selected fibres or filaments.

4.3.7 Calculate the arithmetic mean of the 25 measurements and convert this value to micrometres,using the magnification coefficient of the optical system.

5 Method B: Transverse section

5.1 Principle

A transverse section of a yarn that has been impregnated with resin and cured is viewed under a microscope and the diameter of a given number of fibres or filaments in the yarn is measured.

5.2 Apparatus

5.2.1 Microscope, equipped with the following:

— An eye-piece with a built-in micrometer graticule, the eye-piece and objective together giving an overall magnification of at least ×400 and preferably ×1 000. The resolution of the microscope shall permit measurement to the nearest 0,5 µm or better.

— A system permitting lateral and rotational movement of the microscope stage.

— An illumination system.

This system may be replaced by or used in conjunction with a microprojector on which specimens can be measured using a transparent scale (preferably a curved scale).

The recommended type of microscope is one using plane-polarized light, and an illumination system with a Kohler light source and an Abbe condenser. A green filter may also be used to give better reading accuracy.

5.2.2 Micrometer scale, with 0,01 mm divisions, for calibration of the optical system.

5.2.3 Impregnation system, with fast-curing polyester or epoxide resin.

5.2.4 Moulding assembly (see Figure 1 for an example).

5.2.5 Saw, suitable for cutting specimens.

5.2.6 Polishing device.ISO 1888 pdf download.ISO 1888 pdf download