ISO 24284:2022 pdf download.Metallic coatings — Corrosion test method for decorative chrome plating under a de-icing salt environment.

This document specifies the apparatus, reagents, and procedure to assess the corrosion resistance of chromium electroplated parts in the presence of de-icing salts (especially calcium chloride) in the laboratory.

This method is primarily applicable to decorative parts plated with chromium, especially to exterior (automobile) parts electroplated with nickel-chromium or copper-nickel-chromium.

This document simulates a special corrosion in the presence of hygroscopic and corrosive de-icing salt and conductive mud with a high salt concentration on chromium electroplated deposits during winter.

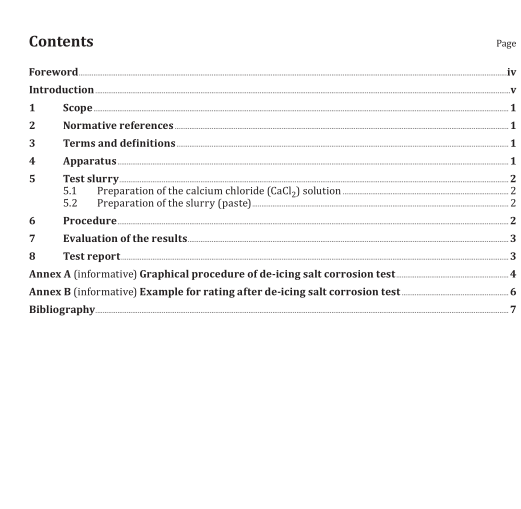

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3696, Water for analytical laboratory use — Specification and test methods

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1 de-icing salt

chemical sprayed to control ice and snow on the roads

EXAMPLE Sodium chloride (rock salt), calcium chloride, and magnesium chloride.

4 Apparatus

4.1 The apparatus shall consist of a humidity chamber, specimen supports, provision for heating the chamber, and provision for air circulation in the chamber. The humidity chamber shall maintain constant temperature (60 °C ± 3 °C) and humidity (30 % ± 5 %).

4.2 The design shall be such that drops of moisture (possibly accumulating on the roof or walls of the chamber, or on the specimen supports) do not fall on the test specimens.

4.3 The construction materials shall not affect the test.

Place the test piece horizontally into a humidity chamber without spilling over the slurry. The humidity chamber shall be set at constant temperature (60 °C ± 3 °C) and humidity (30 % ± 5 % RH) for the test period. The period of test and the number of test specimens shall be specified and agreed upon by the requestor and the laboratory prior to the start of the test. Expose completely all the test pieces to the test environment and place them so that they do not interfere with each other. After the specified testing time, take out the test piece from the humidity chamber. Clean the paste using a clean soft cloth or sponge under running tap water and allow it to dry using tissues, dry clothes, or an air drier.

NOTE 1 Test pieces mentioned in this clause include not only sample test pieces but also real components.

NOTE 2 A graphic representation of the procedure for the de-icing salt corrosion test is given in Annex A.

7 Evaluation of the results

The criteria for the evaluation of the test results shall be given in the specifications of the coating or product tested.

In a typical application of this test, the tested area is inspected under 10× magnification and the observed appearance defects are assessed. An example of a typical evaluation method is given in Annex B.

8 Test report

Unless otherwise prescribed in the specifications, the test report shall contain the following information:

a) a specification of the plating type, the thickness of each layer, the type of chromium layer;

b) the number of test specimens;

c) the preparation method used for the test specimens;

d) the method used to clean the specimens after the test;

e) the temperature and relative humidity inside the humidity chamber;

f) the exposure period;

g) photographs of different areas of the specimens (at 10× magnification) taken before and after the test.ISO 24284 pdf download.ISO 24284:2022 pdf download