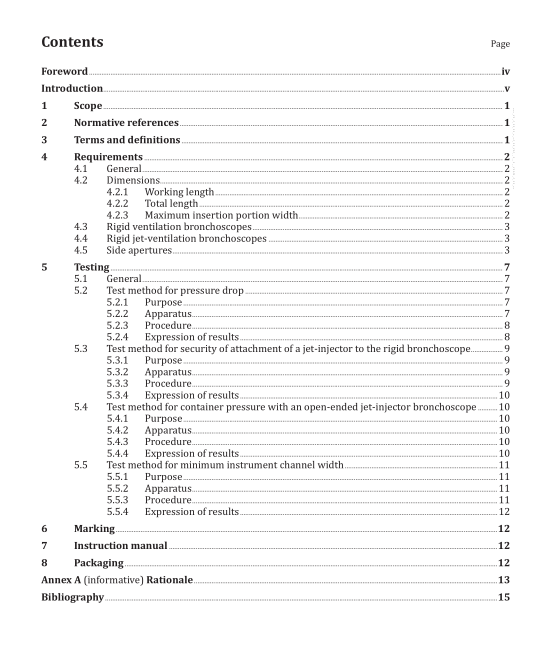

ISO 8600-2:2015 pdf download.Endoscopes – Medical endoscopes and endotherapy devices — Part 2: Particular requirements for rigid bronchoscopes

4 Requirements

4.1 General

Rigid bronchoscopes shall comply with the requirements specified in ISO 8600-1. In addition, rigid bronchoscopes shall also comply with the requirements specified in 4.2 and 4.5; rigid-ventilation bronchoscopes shall also comply with the requirements specified in 4.3 and rigid jet-ventilation bronchoscopes shall also comply with the requirements specified in 4.4.

4.2 Dimensions

4.2.1 Working length

The actual working length of a rigid bronchoscope shall be at least as long as, and not more than, 10 mm longer than the working length stated in the instructions for use provided by the manufacturer.

4.2.2 Total length

The total length shall be in the range ±10 mm to the length stated in instructions for use.

4.2.3 Maximum insertion portion width

The maximum insertion portion width shall be in the range ±1 mm stated in the instructions for use provided by the manufacturer.

4.3 Rigid ventilation bronchoscopes

4.3.1 A rigid ventilation bronchoscope shall be provided with an integral ventilation connector and an end-cap at its proximal end. Provision shall be made for insertion of endoscopes and endoscopic accessories through the end-cap. The end-cap shall not accidentally detach at an airway pressure of less than 4,0 kPa (40 cmH 2 O).

An end-cap may incorporate a transparent window and/or may permit the insertion of an endoscope orendoscopic accessory through the opening or an airtight gasket. Removal or opening of the end-cap for accessory insertion may be achieved by the detachment, rotation or sliding of the end-cap.

4.3.2 A rigid ventilation bronchoscope shall be provided, in a side-arm, either with an integral ventilation connector or shall be provided with a detachable adapter which shall meet the requirements for 15 mm male conical connectors specified in ISO 5356-1 (see Figure 1). This shall not be a connector in which the internal lumen has been reduced. The ventilation connector, when fitted to the rigid ventilation bronchoscope, shall permit to-and-fro ventilation of the patient.

Adding a smaller connector to a 15 mm adapter creates a low dead-space connector. Users should be aware of the danger of using two connected low dead-space connectors, which may cause excessive flow resistance.

A ventilation connector may be located at either side of the rigid bronchoscope (see Figure 1) and may swivel around the shaft of the rigid bronchoscope.

4.4 Rigid jet-ventilation bronchoscopes

4.4.1 Rigid jet-ventilation bronchoscopes shall be provided with a jet-injector intended for jet ventilation.

Jet ventilation through a rigid bronchoscope is usually possible without a separate jet-injector port.

Figure 2 gives examples of different bronchoscopes where jet injection is possible.

4.4.2 When tested in accordance with 5.3, a jet-injector supplied with a bronchoscope shall withstand a minimum force of 20 N without becoming detached.

4.4.3 When tested in accordance with 5.4, the container pressure generated by a rigid jet-ventilation bronchoscope with any jet-injector provided by the manufacturer shall not exceed 6,0 kPa (60 cmH 2 O).

If the bronchoscopist uses jet-injectors other than those provided by the manufacturer, he/she is responsible for its function and performance.

The ventilation pressure developed by any jet-injector depends on the characteristics of the bronchoscope with which it is used or tested. Users should be aware that ventilation pressure can be greatly increased by insertion of any obstruction, e.g. an aspirator or forceps, into the lumen of the rigid bronchoscope.

4.5 Side apertures

4.5.1 Side apertures, if provided, shall be located on the rigid bronchoscope no closer than 5 % of the working length from the distal tip.

4.5.2 The minimum total area of the side apertures shall not be less than the cross-sectional area of the minimum instrument channel width.

4.5.3 The side apertures shall have a smooth rounded finish

5 Testing

5.1 General

In addition to the test methods specified in ISO 8600-1:2013, Clause 5 (where applicable), the test

methods specified in 5.2 to 5.5 apply.

5.2 Test method for pressure drop

5.2.1 Purpose

To determine the pressure drop through the rigid bronchoscope by introducing airflow at a specific flow rate and measuring the corresponding pressure drop expressed as gauge pressure (kPa).

5.2.2 Apparatus

5.2.2.1 Flow-measuring device, capable of measuring flows up to 70 l/min and having an accuracy of ±5 %.

5.2.2.2 Pressure-measuring device, having a time constant >10 s and an accuracy of ±0,2 kPa (±2 cmH 2 O).ISO 8600-2 pdf download.ISO 8600-2 pdf download