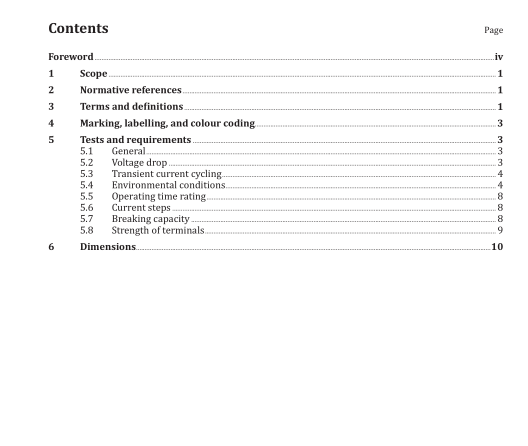

ISO 8820-1:2014 pdf download.Road vehicles — Fuse-links — Part 1: Definitions and general test requirements Marking, labelling, and colour coding

The rated current and rated voltage shall be permanently marked to be externally visible on the fuse-link. In

addition, the current rating shall be shown by colour coding as specified in the applicable part of ISO 8820.

The manufacturer’s name, trademark, and/or symbol shall be marked on the fuse-link insulator.

5 Tests and requirements

5.1 General

5.1.1 General test conditions

If not otherwise specified, all tests shall be done at room temperature (RT) (23 ± 5) °C at a relative humidity (RH) of 45 % to 75 % (standard condition).

At the beginning of the electrical tests, a direct current shall be fixed at the rated value. Measure this current with an appropriate method. If not otherwise specified, no further adjustments during the tests are allowed.

All electrical measurement equipment shall have a tolerance of less than ±2 %.

If not otherwise specified, the supply voltage shall not exceed the rated voltage of the fuse-link.

Mount the fuse-links in a test fixture as specified in the applicable part of ISO 8820 or any alternate fixture with equivalent electrical, mechanical, and thermal properties.

Measurements shall be performed at no forced air flow.

For appropriate cable sizes, see the applicable part of ISO 8820.

Connections shall be made to the fuse-links with copper cables according to ISO 6722. The cable length between the test fixture and the rest of the test set-up shall be (500 ± 50) mm if not otherwise specified.

Measure the connection resistance using a dummy with dimensions as specified in the appropriate part of ISO 8820. Use a current as specified in the appropriate part of ISO 8820 for this measurement.

5.1.2 General performance requirements

The general performance requirements are as follows:

— the marking and/or labelling shall remain legible;

— the colour coding shall remain recognizable;

— after testing, fuse-link shall be removable in one piece from the test fixture by its intended method.

5.2 Voltage drop

5.2.1 Purpose

This test defines and measures the energy consumption of the fuse-link which creates a temperature rise.

5.2.2 Test

If not otherwise specified, this test shall be performed at rated current. Record the voltage drop measured at the points shown in the applicable part of ISO 8820, after the values are stabilized, i.e., the values do not change more than 2 % within a 10 min period.

5.2.3 Requirement

The maximum voltage drop shall not exceed the values given in the applicable part of ISO 8820.

5.3 Transient current cycling

5.3.1 Purpose

This test evaluates the ability of the fuse-link to withstand the energy volume of transient pulses.

5.3.2 Test

Apply a pulse as given in the appropriate part of ISO 8820 (see Figure 1).

5.3.3 Requirement

After transient current cycling for a minimum of 50 000 cycles, the fuse-links shall meet the requirements of the operating time rating test given in the applicable part of ISO 8820.

5.4 Environmental conditions

5.4.1 Purpose

These tests evaluate the ability of the fuse-links to function under environmental stresses.

5.4.2 Mechanical load

5.4.2.1 Test

If a mechanical load test is required, an appropriate test shall be chosen from ISO 16750-3 and agreed between fuse-link and vehicle manufacturer.

5.4.2.2 Requirement

After the mechanical load test, the fuse-links shall meet the requirements of the operating time rating test given in the applicable parts of ISO 8820.

5.4.3 Climatic loads

5.4.3.1 Temperature/humidity cycling

5.4.3.1.1 Test

Subject the fuse-links to a temperature/humidity cycling test as specified in Figure 2. The test sequence is as described below:

a) maintain the samples at standard conditions for 4 h;

b) increase T to (55 ± 2) °C at 95 % to 99 % RH within 0,5 h;

c) maintain T at (55 ± 2) °C at 95 % to 99 % RH for 10 h;

d) decrease T to (-40 ± 2) °C within 2,5 h; the humidity is uncontrolled;

e) maintain T at (-40 ± 2)°C for 2 h; the humidity is uncontrolled;

f) increase T to (120 ± 2) °C within 1,5 h from (-40 ± 2) °C; the humidity is uncontrolled;

g) maintain T at (120 ± 2) °C for 2 h; the humidity is uncontrolled;

h) allow to return to RT within 1,5 h; the humidity is uncontrolled.

At the end of a cycle, the test might be interrupted. During the interruption, the test samples shall remain at the standard conditions. Note the interruption in the test report.

NOTE One cycle consists of 24 h.ISO 8820-1 pdf download.ISO 8820-1-2014 pdf download