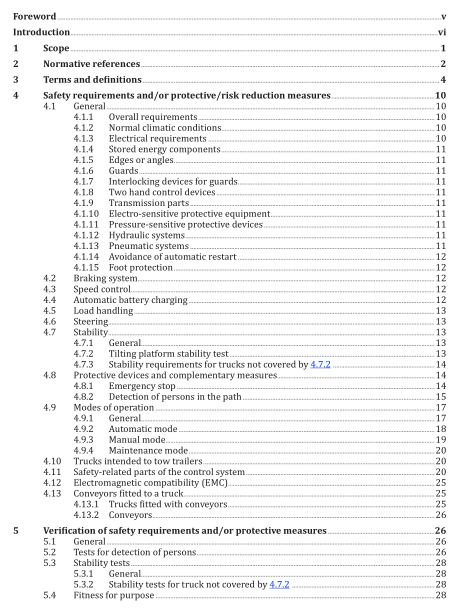

ISO 3691-4:2020 pdf download.Industrial trucks — Safety requirements and verification — Part 4: Driverless industrial trucks and their systems

4.1.14 Avoidance of automatic restart

Trucks shall be designed in such way that an automatic restart is not permitted after the actuation of any of the following:

a) emergency stop device;

b) short stroke bumper, see 4.8.2.1 e);

c) presence of the operator as described in 4.9.3 (e.g. seat, tiller, handles, foot pedal);

d) manual control commands (e.g. throttle, steering wheel, joystick), see 4.9.3.1 c);

e) virtual reachable stop function according to Table A.1, footnote c).

Trucks shall be designed in such way that an automatic restart is not permitted after interruption of power.

4.1.15 Foot protection

Means shall be provided to prevent injury to the feet of persons standing nearby the truck.

Examples of measures are:

a) follow manufacturer specifications of ESPE concerning additional stopping distances margins for feet;

b) reduce clearance of the chassis to equal to or less than 40 mm, for a person wearing safety shoes.

This will prevent feet from being entrapped under the chassis;

c) foot clearance below the chassis according to ISO 3691-1:2011, Figure 5. This will prevent contact with the drive and stabilizing wheels.

4.2 Braking system

The truck shall be equipped with a braking system that is designed to do the following:

a) operate on the interruption of the power supply;

b) activate automatically at the loss of control of the speed or steering;

c) stop the truck within the operating range of the personnel detection means as defined in 4.8.2 in the worst condition in the limits specified by the manufacturer (e.g. speed, friction, floor/ground,gradient, rated load);

d) maintain the truck and its maximum permissible load stationary on the maximum operational gradient specified by the manufacturer.

The safety-related parts of the braking systems shall be in accordance with Table 1, item 1 and item 2.

NOTE Braking systems can consist of one or more braking function (e.g. spring-loaded brake, service brake).

4.3 Speed control

The safety-related parts of the speed control system shall be in accordance with Table 1, item 3 and item 8.

4.4 Automatic battery charging

Automatic charging connections rated above 60 VDC or 25 VAC shall be designed to prevent shock hazards arising from accidental contact with live parts according to IEC 61558-1:2017.

A truck equipped with an automatic charging system shall be designed such that the reachable charging contacts are only activated when the truck is connected to the charging device.

Where the truck is removed from the charging points, the charging contacts of the truck shall be disconnected from the battery.

The safety-related parts of these systems shall be in accordance with Table 1, item 9.

4.5 Load handling

The load-carrying device shall be so designed that the load stays within the limits of position(s) determined by the manufacturer in any operational mode, including an emergency stop and load transfer. This can be achieved by integrating clamps, mechanical locks, stops, etc.

As an alternative, means shall be provided to prevent the truck from moving when the load is not in the designated position on the load carrying device as determined by the manufacturer. This can be achieved by integrating camera, sensing device, switch, etc.

Systems for lifting and tilting shall comply with ISO 3691-1:2011, 4.6.

The safety-related parts of the control systems performing these functions shall be in accordance with Table 1, items 10, 11 and 12.

4.6 Steering

The safety-related parts of the controls for the steering system shall be in accordance with Table 1,item 13.

4.7 Stability

4.7.1 General

The truck shall remain stable in all operating conditions and during all load-handling and travelling movements, including an emergency stop.

The safety-related parts of the controls for stability shall be in accordance with Table 1, item 14.

4.7.2 Tilting platform stability test

Stability for trucks with lift height more than 500 mm, shall be tested according to the applicable standard(s) below:

— ISO 22915-1:2016,

— ISO 22915-2:2018,

— ISO 22915-3:2014,

— ISO 22915-4:2018,

— ISO 22915-5:2014,

— ISO 22915-7:2016,

— ISO 22915-8:2018,

— ISO 22915-9:2014,

— ISO 22915-10:2008,

— ISO 22915-11:2011.ISO 3691-4 pdf download.