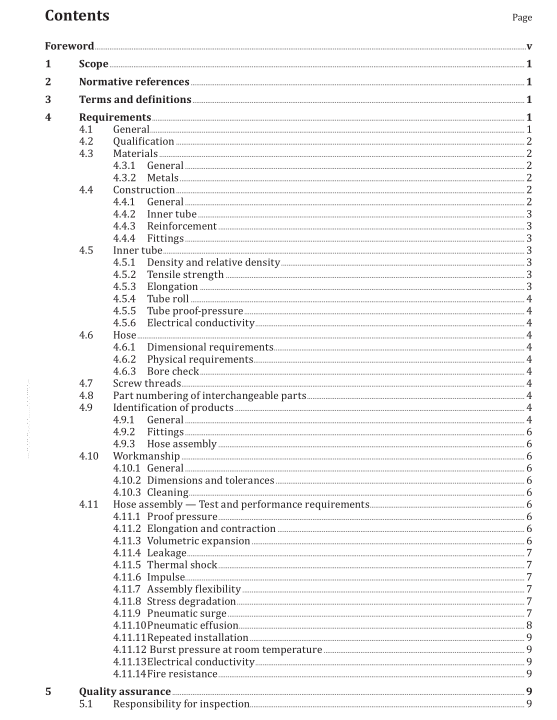

ISO 9528:2022 pdf download.Aerospace — Standard-weight polytetrafluoroethylene (PTFE) hose assemblies, classification 204 °C/ 21 000 kPa — Procurement specification

This document specifies requirements for standard-weight polytetrafluoroethylene (PTFE) hose assemblies for use in aircraft hydraulic systems at temperatures between –55 °C and +204 °C and at a nominal pressure up to 21 000 kPa (210 bar). The hose assemblies are also suitable for use within the same temperature and pressure limitations in aircraft pneumatic systems where some gaseous diffusion through the wall of the PTFE liner can be tolerated.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 2685, Aircraft — Environmental test procedure for airborne equipment — Resistance to fire in designated fire zones

ISO 2859-1, Sampling procedures for inspection by attributes — Part 1: Sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection

ISO 5855-3, Aerospace — MJ threads — Part 3: Limit dimensions for fittings for fluid systems

ISO 6772, Aerospace — Fluid systems — Impulse testing of hydraulic hose, tubing and fitting assemblies

ISO 7258, Polytetrafluoroethylene (PTFE) tubing for aerospace applications — Methods for the determination of the density and relative density

ISO 8829-1:2009, Aerospace — Test methods for polytetrafluoroethylene (PTFE) inner-tube hose assemblies — Part 1: Metallic (stainless steel) braid

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

4 Requirements

4.1 General

The use of these hose assemblies in high-pressure pneumatic storage systems is not recommended.

In addition, installations in which the limits specified in this document are exceeded, or in which the application is not covered specifically by this document, for example for oxygen, shall be subject to the approval of the purchaser.

4.2 Qualification

Hose assemblies supplied in accordance with this document shall be representative of products which have been subjected to and which have successfully passed the requirements and tests specified in this

document.

4.3 Materials

4.3.1 General

The hose assembly materials shall be as described in this document. All materials not specifically described in this document shall be of the highest quality and suitable for the purpose intended.

4.3.2 Metals

Metals used in the hose and fittings shall be corrosion-resistant or titanium and shall conform to the applicable specifications described in Table 1.

4.4 Construction

4.4.1 General

The hose assembly shall consist of

— a seamless PTFE inner tube (see 4.4.2),

— corrosion-resistant steel-wire reinforcement (see 4.4.3), and

— corrosion-resistant steel and/or titanium end fittings (see 4.4.4),

as required to meet the construction and performance requirements laid down in this document and as required for its intended use.

4.4.2 Inner tube

The inner tube shall be of a seamless construction of virgin PTFE resin of uniform gauge; it shall have a smooth bore and shall be free from pitting or projections on the inner surface. Additives may be included in the compound from which the tube is extruded with no more than 2 % of such additives being retained in the mixture.

4.4.3 Reinforcement

The reinforcement shall consist of corrosion-resistant steel wire conforming to the applicable specifications given in 4.3.2. The wires shall be arranged over the inner tube so as to provide sufficient strength to ensure conformity to the requirements laid down in this document.

Broken or missing reinforcing wires shall be cause for rejection; crossed-over reinforcing wires shall not be cause for rejection of the hose assembly.

4.4.4 Fittings

4.4.4.1 General

It shall be proven that all fittings conform to the requirements laid down in this document. Unless otherwise specified by the purchaser, the hose assemblies shall have flareless fittings (24° cone coupling).

4.4.4.2 Insert fittings

Insert fittings shall be manufactured in one piece wherever possible; those made of other than onepiece construction shall be butt-welded, unless otherwise agreed by the purchaser, fabricated from annealed, austenitic, corrosion-resistant steel tubing. Welded and redrawn tubing may be used.ISO 9528 pdf download.ISO 9528 pdf download