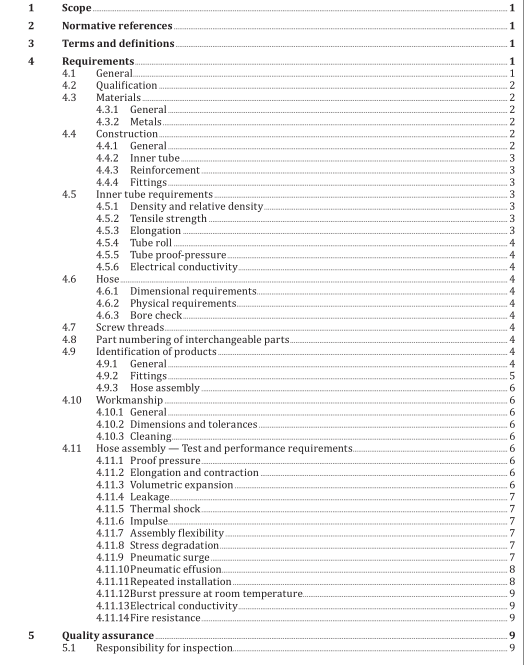

ISO 9938:2022 pdf download.Aerospace — Polytetrafluoroethylene (PTFE) hose assemblies, classification 204 °C/28 000 kPa — Procurement specification

4.4.2 Inner tube

The inner tube shall be of a seamless construction of virgin PTFE resin of uniform gauge; it shall have a smooth bore and shall be free from pitting or projections on the inner surface. Additives may be included in the compound from which the tube is extruded with no more than 2 % of such additives being retained in the mixture.

4.4.3 Reinforcement

The reinforcement shall consist of corrosion-resistant steel wire conforming to the applicable specifications given in 4.3.2. The wires shall be arranged on the outside surface of the inner tube so as to provide sufficient strength to ensure conformity to the requirements laid down in this document. Broken or missing reinforcing wires or buckled wires more than 1,5 mm above the outside diameter surface shall be cause for rejection. Overlapping or crossed-over reinforcing wires shall not be cause for rejection of the flexible hose assembly.

4.4.4 Fittings

4.4.4.1 General It shall be proven that all fittings conform to the requirements laid down in this document. Unless otherwise specified by the purchaser, the hose assemblies shall have flareless fittings (24° cone coupling).

4.4.4.2 Insert fittings Insert fittings shall be manufactured in one piece wherever possible. Those made of other than one- piece construction shall be butt-welded, unless otherwise agreed by the purchaser, fabricated from corrosion-resistant steel tubing or titanium. Welded and redrawn tubing (materials No. 8 and No. 9) may be used for corrosion-resistant steel.

4.5 Inner tube requirements

4.5.1 Density and relative density

The relative density of the hose inner tube shall not exceed 2,155, when tested in accordance with ISO 7258, either method A or method B (as specified in ISO 8829-1). The density shall not exceed 2,204 g/cm 3 , when tested in accordance with ISO 7258, method C (as specified in ISO 8829-1).

4.5.2 Tensile strength

When tested in accordance with ISO 8829-1:2009, 4.2, the longitudinal tensile strength for all sizes of tubes shall be at least 15,1 N/mm 2 1) . When tested in accordance with ISO 8829-1:2009, 4.2, the transverse tensile strength for sizes DN16 and larger shall be at least 12,4 N/mm 2 ; for sizes under DN16, the transverse strength doesn’t need to be tested.

4.5.3 Elongation

When tested in accordance with ISO 8829-1:2009, 4.2, the elongation shall be at least 200 %

4.5.4 Tube roll

The tube shall not leak, split, burst or show any signs of malfunction, when tested through the sequence as specified in ISO 8829-1:2009, 4.3.2.

4.5.5 Tube proof‑pressure

After being subjected to the tube roll test sequence (see 4.5.4), the tube, without reinforcing wires, shall not leak, burst or show any signs of malfunction, when tested as specified in ISO 8829-1:2009, 4.3.3.

4.5.6 Electrical conductivity

When tested in accordance with ISO 8829-1:2009, 4.4, the electrical current shall be equal to or greater than:

a) 10 µA for sizes DN06 to DN12 (inclusive);

b) 20 µA for sizes DN16 and over.

4.6 Hose

4.6.1 Dimensional requirements

The hose assembly dimensions, except for length, shall be as specified in Figure 1 and Table 2.

4.6.2 Physical requirements

Hose assemblies shall conform to the physical and linear density (weight) requirements specified in Table 3.

4.6.3 Bore check

When bent to the appropriate minimum bend radius as specified in Table 3, the hose assembly shall permit the free passage of a solid rigid sphere throughout its length. The diameter of the sphere shall be 90 % of the appropriate minimum internal diameter of the end fittings as specified in Table 2. For elbow fittings, see footnote a in Table 2.

4.7 Screw threads

Unless otherwise specified (see 4.4.4), fitting threads shall be in accordance with ISO 5855-3. A 10 % increase in the tolerance of the fitting thread of the nut following proof testing shall not be cause for rejection of the hose assembly.

4.8 Part numbering of interchangeable parts

All parts conforming to this document and having the same manufacturers or standard part number shall be functionally and dimensionally interchangeable.

4.9 Identification of products

4.9.1 General

The hose assembly and its component parts shall be permanently marked.ISO 9938 pdf download.ISO 9938 pdf download