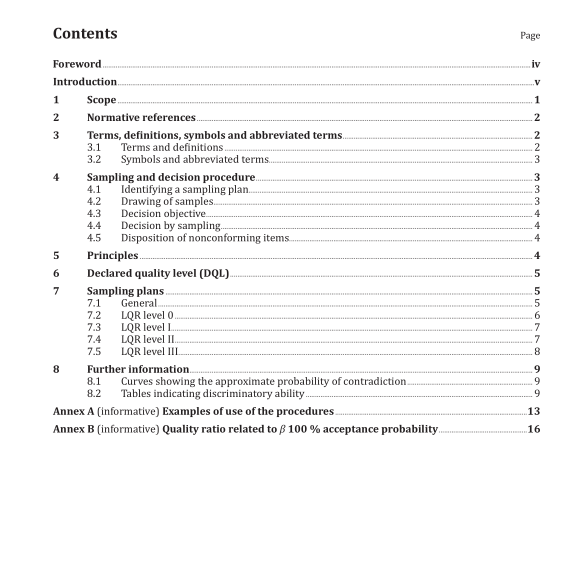

ISO 2859-4:2020 pdf download.Sampling procedures for inspection by attributes — Procedures for assessment of declared quality levels

This document establishes single sampling plans for conformance testing, i.e., for assessing whether the quality level of a relevant audit population (lot, process, inventory, file etc) conforms to a declared value. Sampling plans are provided corresponding to four levels of discriminatory ability.

The limiting quality ratio (LQR) (see Clause 4) of each sampling plan is given for reference. For levels I-III, the sampling plans have been devised so as to obtain a risk no more than 5 % of contradicting a correct declared quality level.

The risk of failing to contradict an incorrectly declared quality level which is related to the LQR is no more than 10 %. The sample sizes for level 0 are designed in a way that the LQR factors of the sampling plans are compatible with the LQR factors for level I. In contrast to the procedures in the other parts of the ISO 2859 series, the procedures in this document are not applicable to acceptance assessment of lots. Generally, this document mainly focuses on controlling type I error, which differs from the balancing of the risks in the procedures for acceptance sampling.

This document can be used for various forms of quality inspection in situations where objective evidence of conformity to some declared quality level is to be provided by means of inspection of a sample.

The procedures are applicable to entities such as lots, process output, etc. that allow random samples of individual items to be taken from the entity. The sampling plans provided in this document are applicable, but not limited, to the inspection of a variety of targets such as:

— end items;

— components and raw materials;

— operations;

— materials in process;

— supplies in storage;

— maintenance operations;

— data or records;

— administrative procedures;

— accounting procedures or accounting entries;

— internal control procedures.

This document considers two types of quality models for discrete items and populations, as follows.

i) The conforming-nonconforming model, where each item is classified as conforming or nonconforming, and where the quality indicator of a population of items is the proportion p of nonconforming items, or, equivalently, the percentage 100 p of nonconforming items.

ii) The nonconformities model, where the number of nonconformities is counted on each item, and where the quality indicator of a population of items is the average number λ of nonconformities found on items in the population, or, equivalently, the percentage 100 λ of nonconformities on items in the population.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3534-1, Statistics — Vocabulary and symbols — Part 1: General statistical terms and terms used in probability

ISO 3534-2, Statistics — Vocabulary and symbols — Part 2: Applied statistics

ISO 9000, Quality management systems — Fundamentals and vocabulary

3 Terms,definitions, symbols and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 3534-1, ISO 3534-2 and

ISO 9000 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1.1 non-rejection number

c largest number of nonconforming items or nonconformities, respectively, found in the sample from the population under investigation that does not lead to contradiction of the declared quality level

3.1.2 quality ratio QR

ratio of the actual quality level to the declared quality level of the entity under investigation

3.1.3 limiting quality ratio

LQR value of the quality ratio that is limited to a small risk of failing to contradict an incorrect declared

quality level

Note 1 to entry: In this document, the risk of failing to contradict an incorrect declared quality level is no more

than 10 %.

3.1.4 audit population

totality of items under audit inspection

3.1.5 audit population conformance

state of the audit population fulfilling imposed requirements.ISO 2859-4 pdf download.ISO 2859-4 pdf download