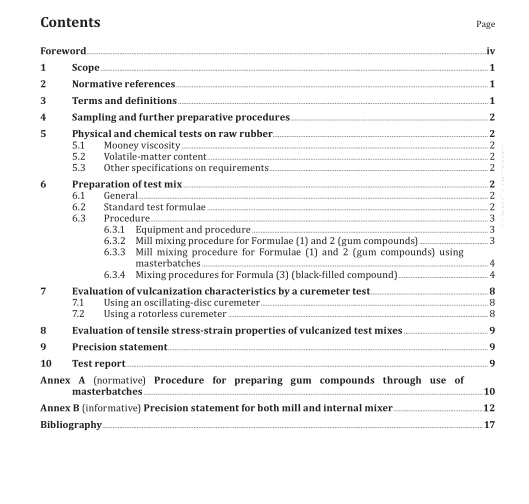

ISO 1658:2022 pdf download.Natural rubber (NR) — Evaluation procedure.

4 Sampling and further preparative procedures

4.1 A laboratory sample of mass approximately 1,5 kg shall be prepared by the method described in ISO 1795.

4.2 The rubber shall be homogenized in accordance with ISO 1795.

4.3 Preparation of the test samples shall be in accordance with ISO 1795.

5 Physical and chemical tests on raw rubber

5.1 Mooney viscosity

Determine the Mooney viscosity in accordance with ISO 289-1 on a test sample prepared as indicated in 4.3. Record the result as ML(1+4) at 100 °C.

5.2 Volatile-matter content

Determine the volatile-matter content by the oven method specified in ISO 248-1 on a test sample prepared as indicated in 4.3.

5.3 Other specifications on requirements

Any specific values for physical and chemical properties other than the above (5.1 and 5.2) shall be based upon the grades given in ISO 2000:2020, Table 2.

6 Preparation of test mix

6.1 General

The following standard formulae and mixing procedures are recommended:

a) two gum-stock formulae for comparative testing of the vulcanization characteristics of natural rubber for use in non-black-filled compounds;

b) a black-filled formula for comparative testing of natural rubber for use in black-filled compounds;

c) a mill mixing procedure including masterbatches for the two gum-stock formulae;

d) a mill mixing procedure and a laboratory internal mixer (LIM) mixing procedure for the blackfilled formula.

NOTE The black-filled formula [Formula (3) in Table 1] can also be used for comparative testing of isoprene rubbers (IRs).

6.2 Standard test formulae

The standard test formulae are given in Table 1.

The materials shall be national or international standard reference materials.

6.3 Procedure

6.3.1 Equipment and procedure

Equipment and procedure for the preparation, mixing and vulcanizing shall be in accordance with ISO 2393.

6.3.2 Mill mixing procedure for Formulae (1) and 2 (gum compounds)

The standard laboratory mill batch mass, in grams, shall be four times the formulation batch mass [i.e.

110,5 g × 4 = 442 g, for Formula (1)]. Maintain the surface temperature of the rolls at 70 °C ± 5 °C and a good rolling bank at the nip of the rolls during mixing. If this is not obtained with the nip settings specified hereunder, small adjustments to the mill openings might be necessary.

a) Pass the rubber twice between the rolls without banding, with the mill opening set at 0,2 mm.

b) Band the rubber with the mill opening set at 1,4 mm. When a smooth band has been obtained, adjust the mill opening to 1,8 mm.

c) Add the zinc oxide, the stearic acid, the sulfur and the MBT or TBBS. 4

d) Make three 3/4 cuts from each side. 3

e) Cut the batch from the mill. Set the mill opening to 0,8 mm and pass the rolled batch endwise through the rolls six times.

f) Check the mass of the batch (see ISO 2393). If the mass of the batch differs from the theoretical value by more than + 0,5 % or − 1,5 %, discard the batch and remix.

g) Cut sufficient material from the batch for curemeter testing and, if required, for determination of the Mooney viscosity of the unvulcanized batch in accordance with ISO 289-1. Sheet the batch to approximately 2,2 mm for preparing test slabs or to the appropriate thickness for preparing ISO ring test pieces.

h) Condition the batch for 2 h to 24 h after mixing and prior to vulcanizing, if possible at standard tem- perature and humidity as defined in ISO 23529.

6.3.3 Mill mixing procedure for Formulae (1) and 2 (gum compounds) using masterbatches Compounding materials such as accelerators, sulfur or fillers can be incorporated into the rubber as masterbatches. This technique improves the accuracy of compounding-material incorporation and is also more convenient. The procedure for preparing masterbatches and test mixes for the gum compounds shall be as given in Annex A.

6.3.4 Mixing procedures for Formula (3) (black-filled compound)

6.3.4.1 Mill mixing

6.3.4.1.1 Measurement of rapid plasticity number

Load the rubber on to the mill with the mill opening set at 0,5 mm. Masticate until a smooth band and rolling bank are obtained. After mastication, determine the rapid plasticity number in accordance with ISO 2007. The rapid plasticity number shall not exceed 45, which is approximately equivalent to a viscosity of 70 Mooney units determined in accordance with ISO 289-1.

6.3.4.1.2 Mixing

The standard laboratory mill batch mass, in grams, shall be two times the formulation batch mass (i.e. 144,95 g × 2 = 289,9 g, for Formula (3). Maintain the surface temperature of the rolls at 70 °C ± 5 °C and a good rolling bank at the nip of the rolls during mixing. If this is not obtained with the nip settings specified hereunder, small adjustments to the mill openings may be necessary.ISO 1658 pdf download.ISO 1658 pdf download